Simultaneous preparation of binary and ternary high-performance composite aerogels from iron tailings

A technology of composite airgel and iron tailings, applied in chemical instruments and methods, iron oxide, colloid chemistry, etc., can solve the problem of strict requirements for supercritical drying equipment, unfavorable large-scale industrialization promotion, inability to prepare iron oxide, etc. Problems, achieve excellent adsorption potential, improve functionality and added value, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

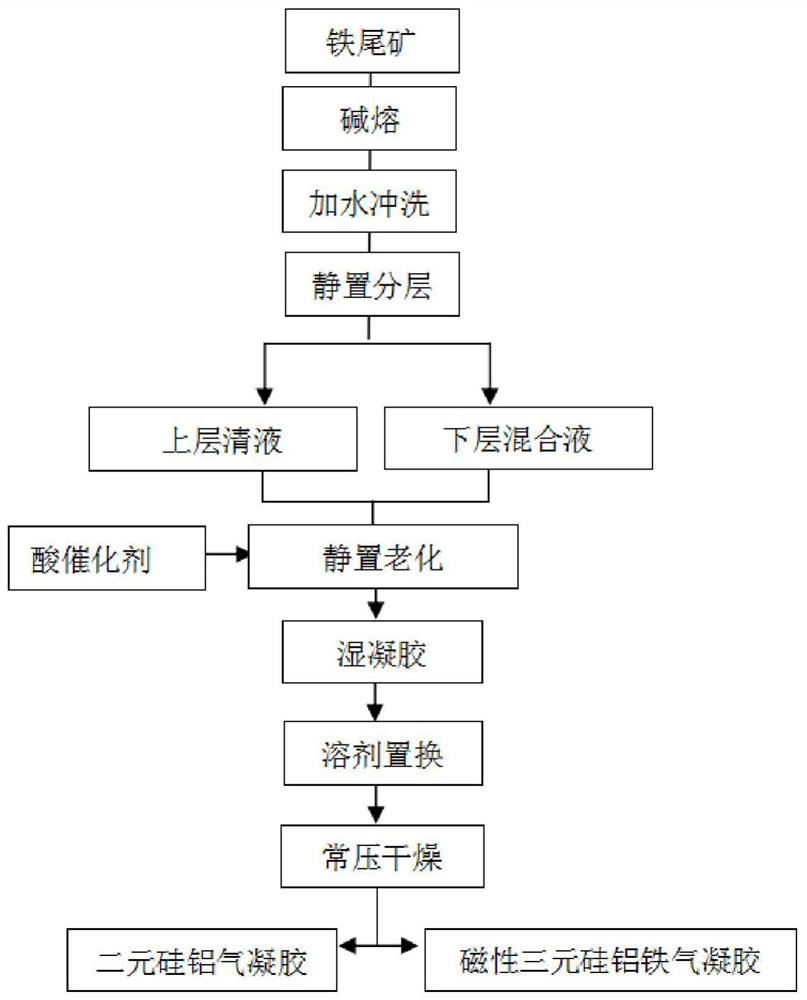

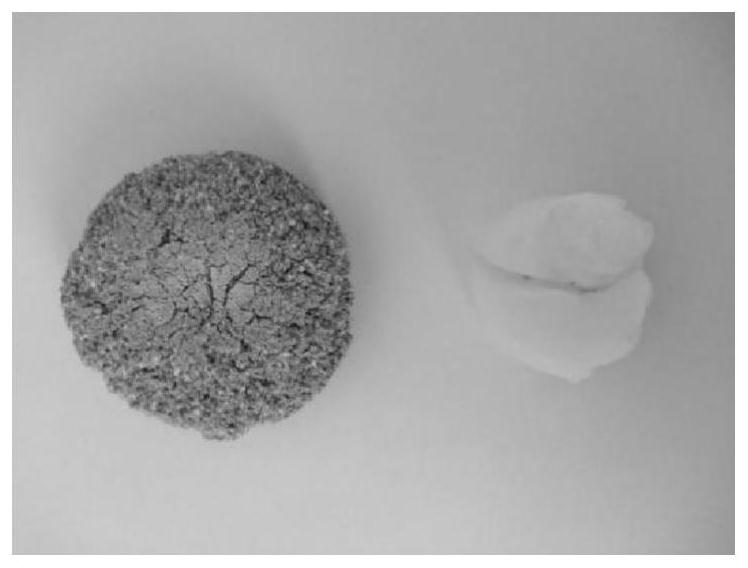

[0027] A method for simultaneously preparing binary and ternary high-performance composite aerogels by utilizing iron tailings, the specific preparation steps are as follows: (1) powdered iron tailings with a size of more than 50 meshes and powdered sodium hydroxide in a mass ratio of 1 : 1 Put it into the crucible and mix it evenly, put the crucible into the muffle furnace, set the heating rate of the muffle furnace to be 5 ℃ / min, heat it to 700 ℃ and keep it for 4 hours to obtain the iron tailings and sodium hydroxide after the reaction. The mixture was washed four times with deionized water at a solid mass to liquid volume ratio of 1:20 to obtain a washing solution.

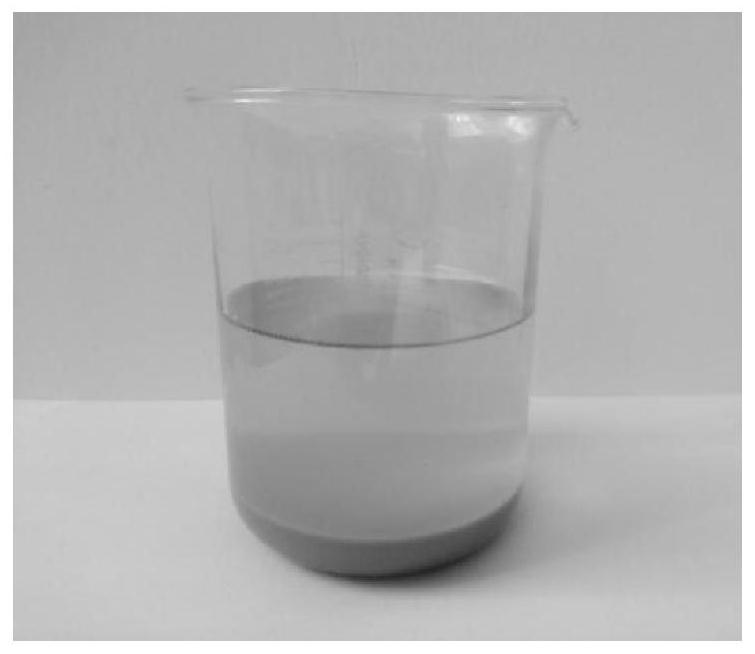

[0028] (2) After standing for 30 minutes, the lotion was obviously stratified, and the supernatant was drawn into other glass containers. Add 5% hydrochloric acid + ascorbic acid (mass ratio 2:1) into two containers respectively, adjust the liquid in the container to pH=9.1, and let the liquid in the two conta...

Embodiment 2

[0033] A method for simultaneously preparing binary and ternary high-performance composite aerogels by utilizing iron tailings, the specific preparation steps are as follows: (1) powdered iron tailings with a size of more than 50 meshes and powdered sodium hydroxide in a mass ratio of 1 : 2 Put it into the crucible and mix it evenly, put the crucible into the muffle furnace, set the heating rate of the muffle furnace to be 5 ℃ / min, heat to 780 ℃ and keep the temperature for 3.5 hours to obtain the iron tailings and sodium hydroxide after the reaction. The mixture was washed 6 times with deionized water at a solid mass to liquid volume ratio of 1:30 to obtain a washing solution.

[0034] (2) After standing for 40 minutes, the lotion was obviously stratified, and the supernatant was drawn into other glass containers. The mass fraction of 5% sulfuric acid + ascorbic acid (mass ratio 2:1) was added to the two containers respectively to adjust the liquid in the container to pH=9.3,...

Embodiment 3

[0039] A method for simultaneously preparing binary and ternary high-performance composite aerogels by utilizing iron tailings, the specific preparation steps are as follows: (1) powdered iron tailings with a size of more than 50 meshes and powdered sodium hydroxide in a mass ratio of 1 : 2.5 Put it into the crucible and mix it evenly, put the crucible into the muffle furnace, set the heating rate of the muffle furnace to be 5 ℃ / min, heat it to 850 ℃ and keep it for 3 hours to obtain the iron tailings and sodium hydroxide after the reaction. The mixture was washed 8 times with deionized water at a solid mass to liquid volume ratio of 1:40 to obtain a washing solution.

[0040] (2) The lotion is obviously layered after standing for 50 minutes, suck the supernatant into other glass containers, and add phosphoric acid + tartaric acid (mass ratio 3:1) with a mass fraction of 10% into two containers to adjust the container. Medium liquid pH = 9.7, and the liquids in both containers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com