Oxygen-doped carbon-based nickel carbide nano composite material as well as preparation method and application thereof

A nano-composite material and nickel carbide technology, which is applied in the direction of carbon compound catalysts, chemical instruments and methods, hydrogenation hydrocarbon production, etc., can solve the problems of heteroatom doping and regulation of composite materials, and achieve low cost, performance improvement, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]Another aspect of the present invention provides a method of preparing the oxygen-doped carbon-based nickel nickel nanocomposites, including steps as follows:

[0044]Preparation of the precursor of the nickel source, no nitrogen-free organic carboxylic acid and alkali metal salt;

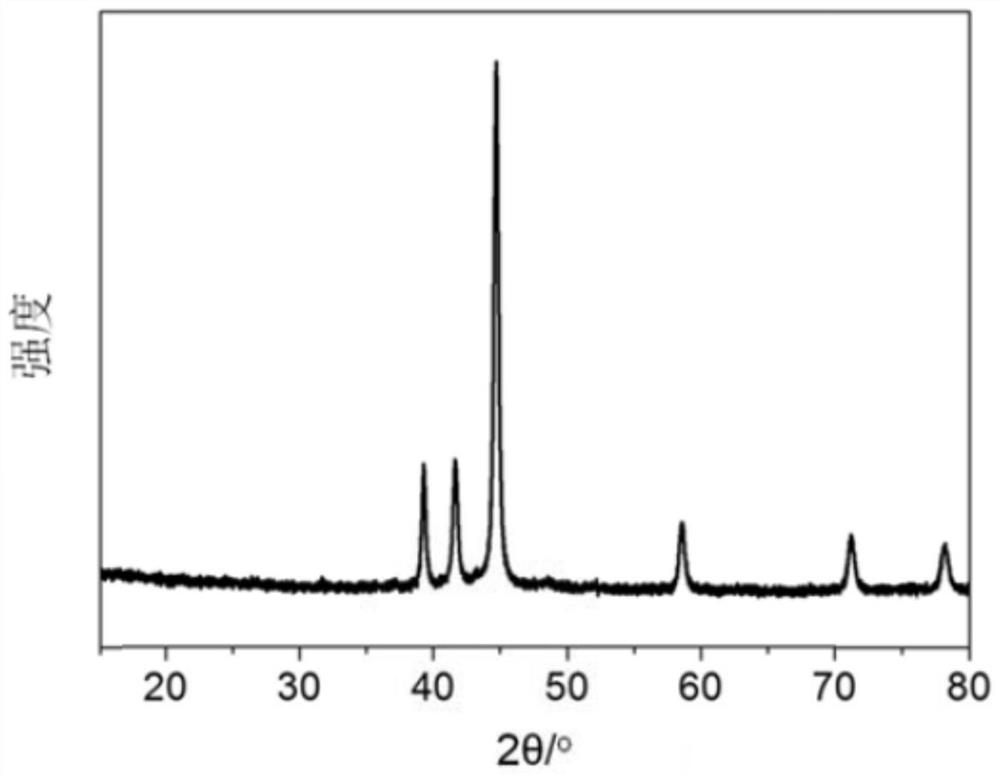

[0045]The precursor was picked under an inert atmosphere to obtain a nanocomposite; wherein the pyrolysis temperature was 310 ° C to 340 ° C.

[0046]According to the present invention, in an early study, the inventors have found that a nickel-coated nanocomposites can be obtained by a method of pyrolysis by precursor, for example, patented CN 109309213A discloses a carbon cladding nickel nanocomposite and a preparation method thereof. Among them, the temperature of the precursor constant temperature section is 425 ° C to 800 ° C. In fact, the preparation temperature range of the preparation of carbon coated nickel nanoparticles in the present pyrolysis method is also usually carried out at the foregoing te...

Embodiment 1

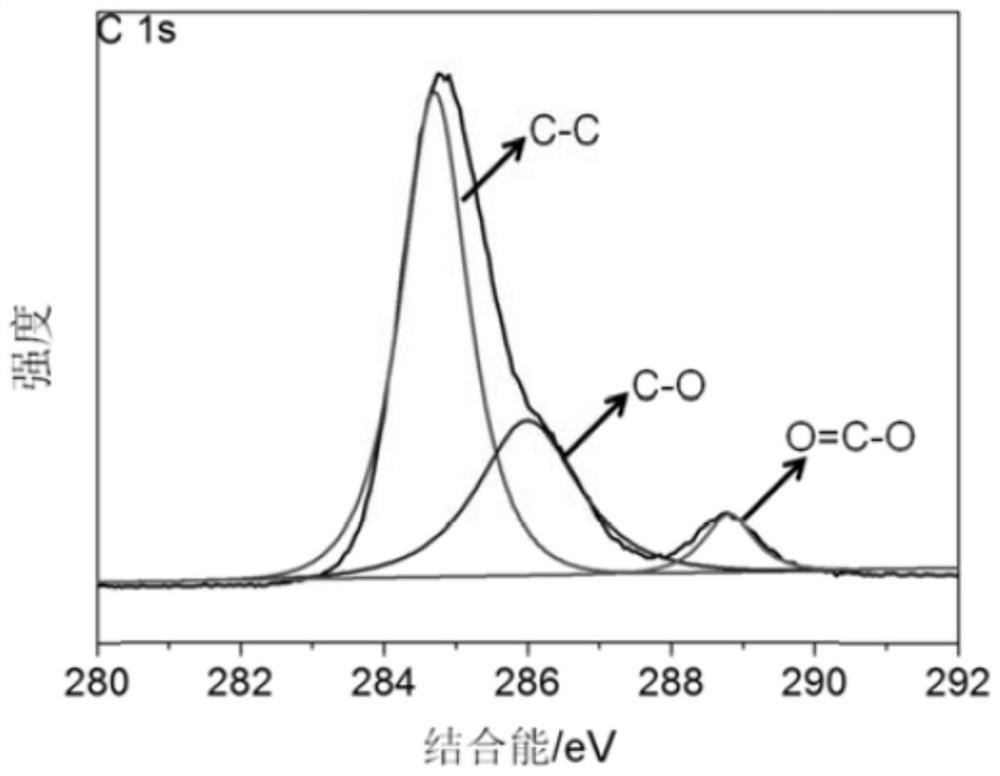

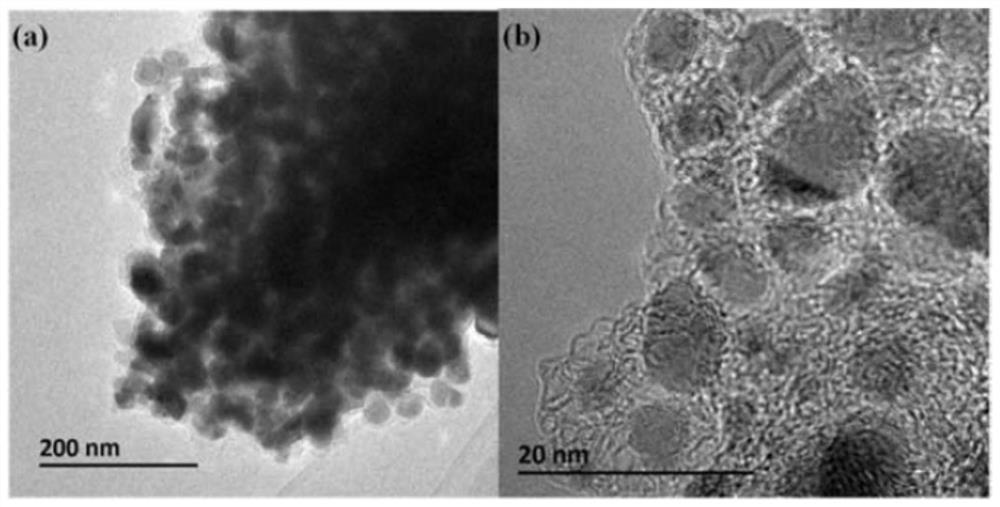

[0066]This example is used to illustrate the preparation of oxygen-doped carbon-based nickel nickel nanocomposites of the present invention.

[0067]1) Weigh 10.51 g (50 mmol) of a hydrated citric acid, 4.64 g (50 mmol) nickel hydroxide, 5.84 g (100 mmol) sodium chloride added 150 ml of deionized water, stirred at 110 ° C to obtain a uniform solution, and continued heating steam Dry, obtain the solid after polishing to get the precursor.

[0068]2) Take 7G Step 1) The resulting precursor is placed in the porcelain boat, and then the porcelain boat is placed in the constant temperature zone of the tube furnace, and the nitrogen gas, the flow rate is 100 ml / min, and the rate of temperature is heated to 330 ° C at a rate of 1 ° C / min. After 150 min, the constant temperature stopped heating and cooled to room temperature under a nitrogen atmosphere.

[0069]3) Transfer the composite of the porcelain to the porcelain obtained by step 2) to the flask, add 50 ml of deionized water, stirred at 6...

Embodiment 2

[0073]This example is used to illustrate the preparation of oxygen-doped carbon-based nickel nickel nanocomposites of the present invention.

[0074]1) Weigh 10.51 g (50 mmol) of a hydrated citric acid, 4.64 g (50 mmol) nickel hydroxide, 11.69 g (200 mmol) sodium chloride, add 150 mL of deionized water, stirred at 110 ° C to obtain a uniform solution, and continue to heat soon Dry, obtain the solid after polishing to get the precursor.

[0075]2) Take 8G Step 1) The precursor is placed in the porcelain boat, then the porcelain boat is placed in the constant temperature zone of the tube furnace, and the flow of nitrogen, 100 ml / min, and warm up at a rate of 1.5 ° C / min to 330 ° C After 150 min, the constant temperature stopped heating and cooled to room temperature under a nitrogen atmosphere.

[0076]3) Transfer the composite of the porcelain to the porcelain obtained by step 2) to the flask, add 50 ml of deionized water, stirred at 60 ° C for 20 minutes, filtrate, dry the filter cake at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com