Mechanically enhanced gelatin chilled hydrogel as well as preparation method and application thereof

A technology of freezing water and hydrogel, which is applied in medical science, absorbent pads, non-active ingredients of polymer compounds, etc., can solve the problems of short degradation cycle, limited promotion, monomer residue, etc., and achieve good biocompatibility and prolong life. The effect of the degradation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Preparation of low solid content jelly (concurrently load-bearing test)

[0041] (1) Preparation of GelMA and SF-GMA

[0042] Dissolve 1g of gelatin in 10ml of 1×PBS buffer at 50°C, stir for 30 minutes until the gelatin is completely dissolved, use a micro-injection pump to continuously inject 0.6ml of methacrylic anhydride within 30 minutes, and then continue to react for 3 hours. The product was transferred to an 8-12kDA dialysis bag, and dialyzed at 40°C, the water was changed twice a day for 7 days, and the dialyzed product was freeze-dried to obtain white spongy methacrylylated gelatin (GelMA). Store at low temperature.

[0043] Add 1g of silk fibroin to 7ml of saturated lithium bromide solution at 60°C and stir for 40 minutes to dissolve it to obtain a silk fibroin solution, inject 0.3ml of glycidyl methacrylate into the silk fibroin solution, and stir for 3 hours to react , the stirring rate is 100-250rpm, the product is transferred to a 8-12kDA d...

Embodiment 2

[0050] Embodiment 2: preparation of higher solid content jelly

[0051] (1) Preparation of GelMA, SF-GMA and APS solutions

[0052] Prepare GelMA, SF-GMA solution, etc. according to the method of Example 1, weigh 0.45g APS and add it into 15ml ultrapure water, stir until APS is completely dissolved, and place the APS solution in a refrigerator at 4°C for use.

[0053] (2) Preparation of higher solid content (15%) GelMA / SF-GMA composite frozen hydrogel

[0054] Dissolve 1.2g of GelMA in 2.182ml of deionized water, then add 6.818ml of concentrated SF-GMA solution with a mass fraction of 8.8%, let stand at 40°C for 5min and stir well, then add 60μl of TEMED and mix well, and finally add 3ml of APS solution and stirred for 10s to mix the material, then divided into molds and stored at -30°C for cross-linking treatment (inducing free radical cross-linking), the time of cross-linking treatment is 24h, induction Frozen hydrogels form.

[0055] (3) Post-treatment of jelly

[0056]...

Embodiment 3

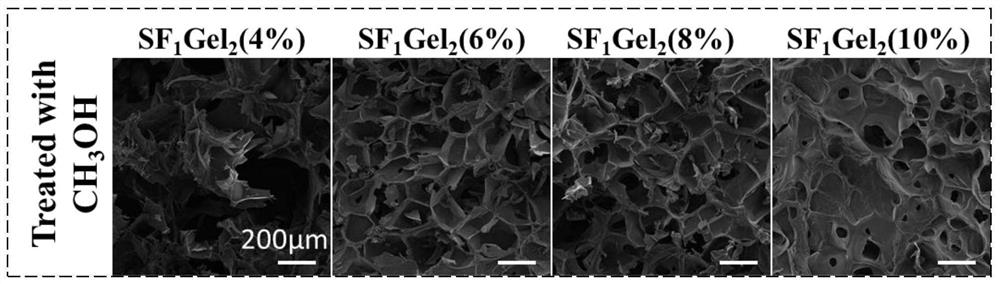

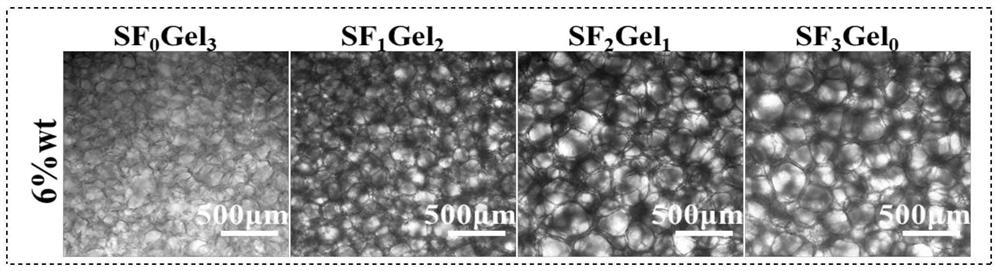

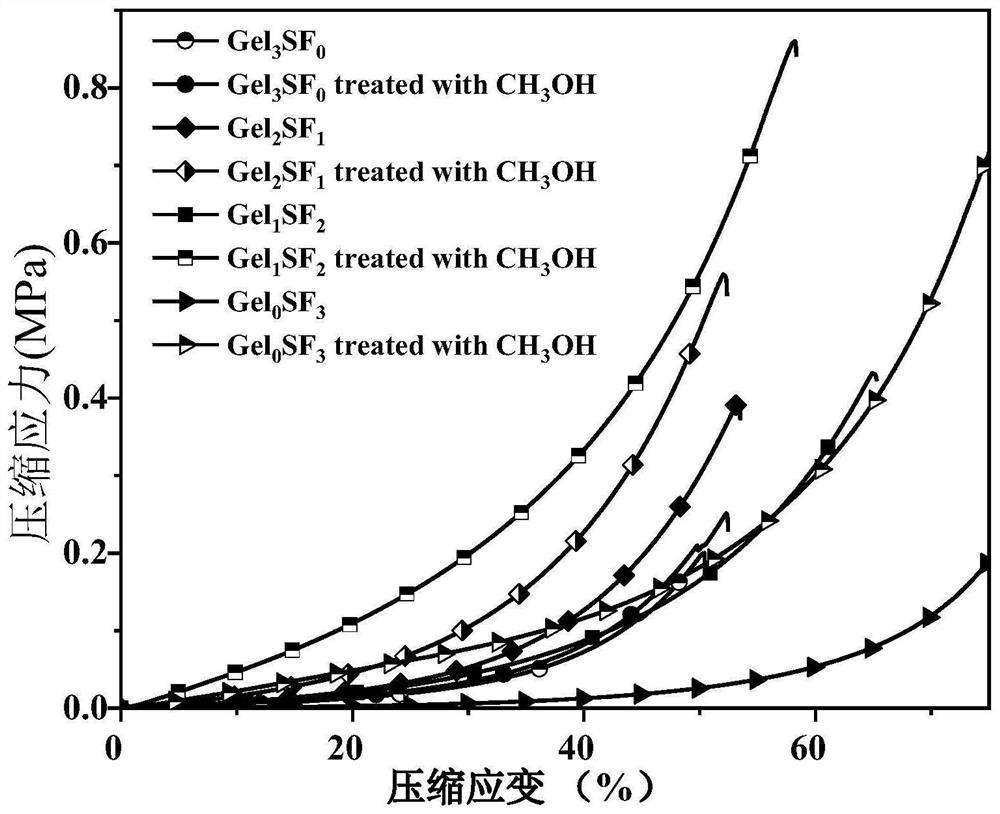

[0057] Example 3: Preparation of jelly with different solid content (and SEM morphology characterization)

[0058] (1) Preparation of GelMA, SF-GMA and APS solutions:

[0059] Prepare GelMA and SF-GMA solutions according to the method of Example 1, weigh 0.45g APS and add it to 15ml ultrapure water, dissolve it and place it in a refrigerator at 4°C for use.

[0060] (2) Preparation of GelMA / SF-GMA composite jelly with different solid contents:

[0061] In a series of vials, add the components of the hydrogel precursor solution in sequence according to the parameters in Table 1 and mix thoroughly. Finally, add the ammonium persulfate solution and stir for 10 seconds to mix the precursor solution, and then immediately transfer it to the mold and stored at -20°C for 12 hours to induce frozen hydrogel formation.

[0062] Table 1: Component ratios of frozen hydrogels with different solid contents

[0063]

[0064](3) Post-processing and characterization of frozen hydrogels

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com