Visual fluorescent fiber as well as preparation method and application thereof

A fluorescent fiber and fiber technology, which is applied in the fields of material synthesis chemistry and clinical medicine, can solve problems such as the lack of methods for threading tubes and the difficulty of fast and accurate threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Another aspect of the embodiments of the present invention also provides a method for preparing the above-mentioned visible fluorescent fiber, including:

[0038] The core layer fiber doped with fluorescent material is prepared, and the shell layer is coated on the surface of the core layer fiber.

[0039] In some preferred embodiments, the preparation method of the visible fluorescent fiber includes: injecting the cellulose solution doped with the fluorescent material into a coagulation bath containing a dehydrating solvent and a cationic surfactant, undergoing wet stretching and drying to obtain core layer fibers, the cellulose solution contains 1-10wt% cellulose material and 0.01-2wt% fluorescent material.

[0040] Alternatively, a calcium alginate solution doped with a fluorescent material at a concentration of 1-10% is injected into a coagulation bath containing metal cations and cationic surfactants, subjected to wet stretching and dried to obtain core layer fiber...

Embodiment 1

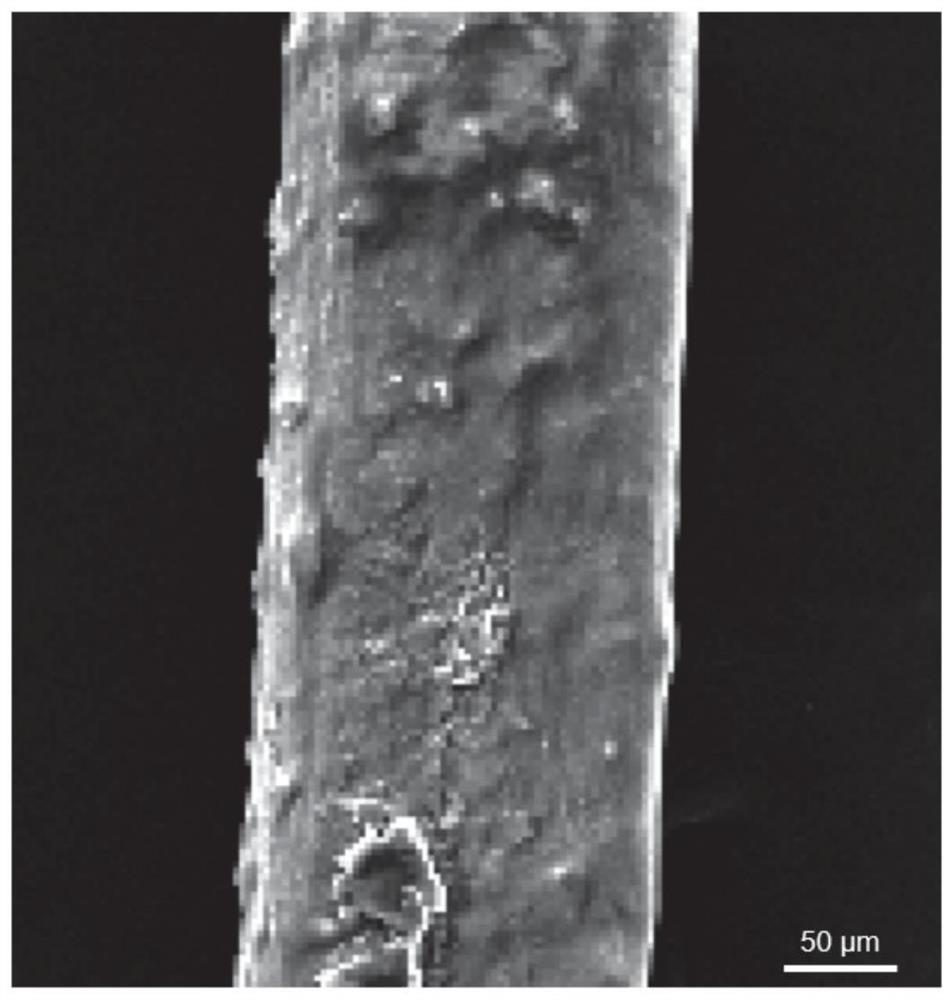

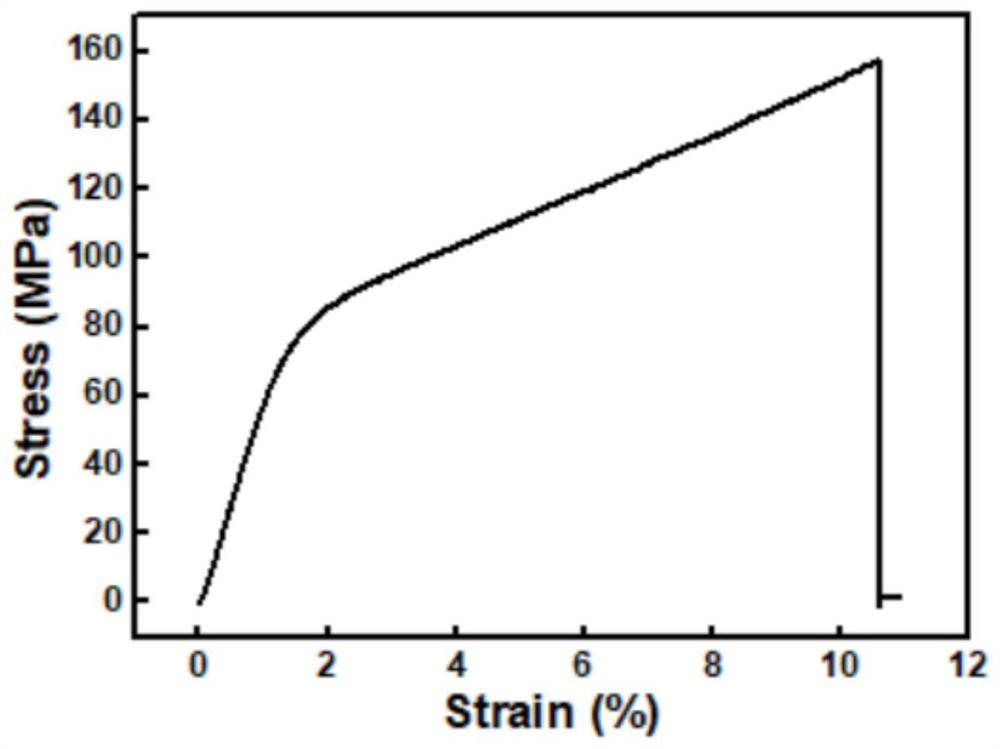

[0052] Example 1: Blend 10 mg CTAB-InP@ZnS quantum dots (or 10 mg Nile Red), 10 g sodium alginate, and 490 g deionized water, stir vigorously at 60°C for 3 hours, vacuum pump to remove air bubbles, and remove the pre-liquid Put it into a plastic syringe, and inject it into the coagulation bath through a steel pipe with an inner diameter of 0.41mm and a length of 15cm at a speed of 5ml / min. The composition of the coagulation bath is 0.1mol / L CaCl 2 and 0.1mmol / L CTAB, after soaking in the coagulation bath for 10min, the fibers were washed in deionized water to remove Ca on the surface 2+ and CTAB, then the fibers were naturally air-dried in an air with a humidity of 50%, and the resulting fibers were observed by an environmental scanning electron microscope, and the entire fiber diameter was 150±10 μm; the 10cm core layer fiber was placed in 50ml of ethanol, 1ml of ethyl orthosilicate ester, 10ml of 28% ammonia water mixed solution, heated at 60°C, stirred vigorously for 6 hour...

Embodiment 2

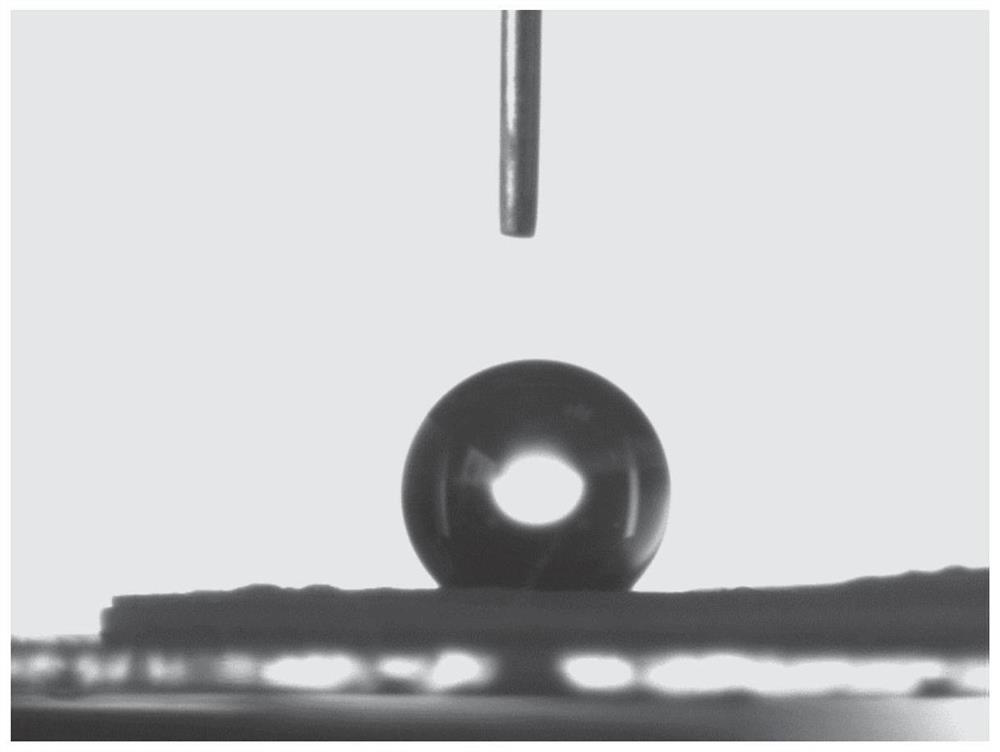

[0053] Example 2: Blend 10 mg CTAB-InP@ZnS quantum dots (or 10 mg Nile Red), 20 g cellulose nanofibers, and 480 g deionized water, stir vigorously for 3 hours, remove air bubbles by vacuum pumping, and put the pre-liquid into a plastic syringe , at a speed of 5ml / min, through a steel pipe with an inner diameter of 0.41mm and a length of 15cm, inject it into the coagulation bath. The coagulation bath consists of acetone and 0.1mmol / LCTAB. Fix it to make it dry naturally in the air with a humidity of 50%. The obtained fiber is observed by an environmental scanning electron microscope. The monofilaments inside the macroscopic fiber are closely arranged, the orientation is high, the surface is smooth, and the diameter of the entire fiber is 150 ± 10 μm; Dissolve 0.1 g of fluorinated silicon dioxide particles in 10 ml of tetrahydrofuran, ultrasonically treat for 30 min, then place a 10 cm core layer fiber in tetrahydrofuran dissolved in fluorinated silicon dioxide nanoparticles, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com