High-density microalgae bio-membrane reactor based on membrane aeration and membrane concentration and algae culture method thereof

A technology of microalgae bio-membrane reactor, applied in the direction of photobioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc. Economically feasible overall system and other issues, to achieve the effects of reducing energy consumption, increasing growth rate, and increasing growth metabolic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

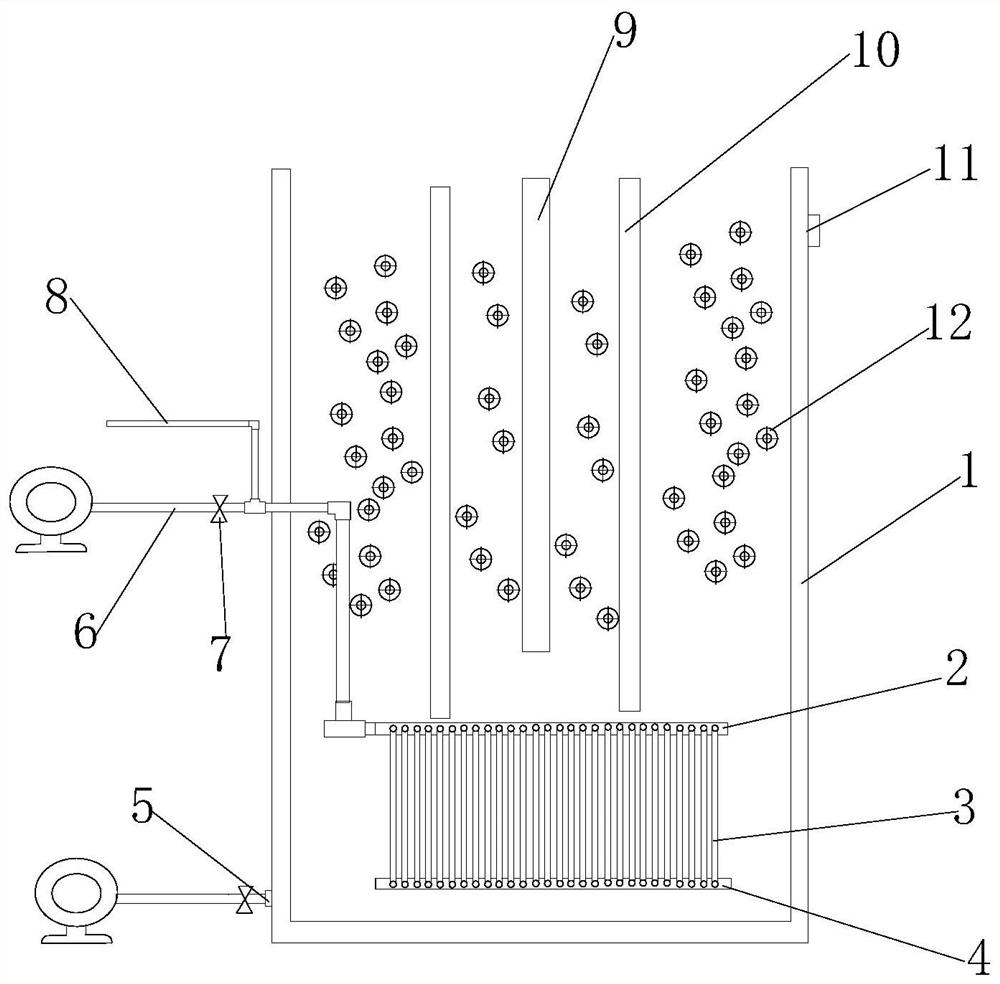

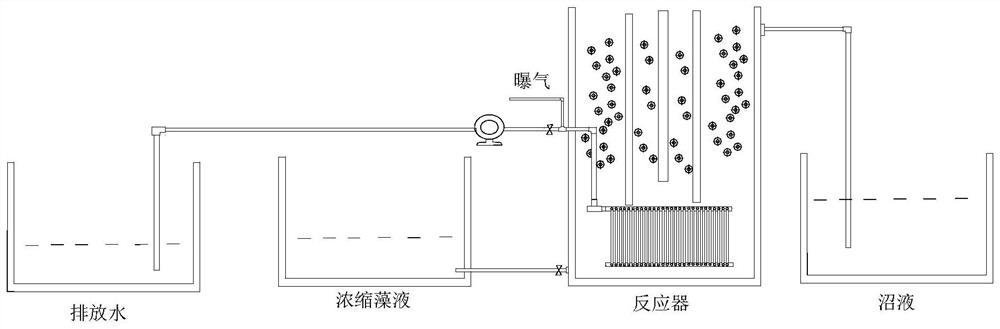

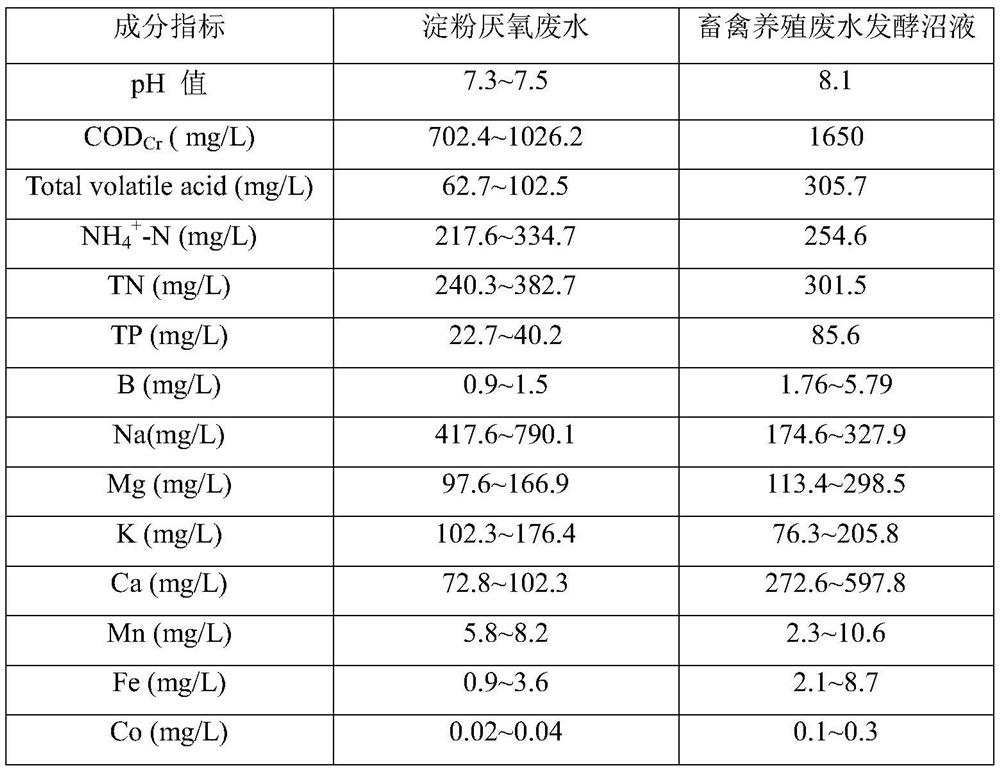

Embodiment 1

[0033] Such as figure 2 As shown, the anaerobic fermentation liquid of starch processing wastewater is used to cultivate Chlorella vulgaris, the anaerobic fermentation liquid enters the main body of the photobioreactor through the wastewater culture liquid tank, and the aeration component is adjusted to control the carbon dioxide flow rate of the hollow fiber membrane module into the reactor to achieve In the state of micro-nano aeration, at the same time, the microalgae membrane-loaded filler in the reactor is maintained in a suspended growth state, and the ventilation rate is controlled at 0.15-0.2L / min. The hollow fiber membrane module is a microfiltration membrane, and the material is a silicone hollow fiber membrane. The aperture is 0.01-0.1 μm, and the light component is adjusted to control the light intensity from 3000 to 6000 lux, and the light-to-dark time ratio is 12h:12h. When the microalgae biofilm reaches the stable growth stage, the hydraulic retention time is 5...

Embodiment 2

[0035] Such as figure 2As shown, the fermentation biogas slurry of livestock and poultry breeding wastewater is used to cultivate Chlorella pyrenoidosa, the acidification solution enters the main body of the photobioreactor through the wastewater culture solution tank, and the aeration component is adjusted to control the carbon dioxide flow rate of the hollow fiber membrane module into the reactor to achieve micro Nano-aeration state, while keeping the microalgae membrane-loaded filler in the reactor in a suspended growth state, the ventilation rate is controlled at 0.15-0.2L / min, the hollow fiber membrane module is a microfiltration membrane, and the material is organic silicon hollow fiber membrane silk. 0.01-0.1μm, adjust the lighting components, so that the light intensity is controlled to 3000-6000lux, and the light-to-dark time ratio is 12h:12h. When the microalgae biofilm reaches the stable growth stage, the hydraulic retention time is 5-8 days. At this time, the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com