Silicon dioxide composite film with disilane precursor as well as preparation method and application of silicon dioxide composite film

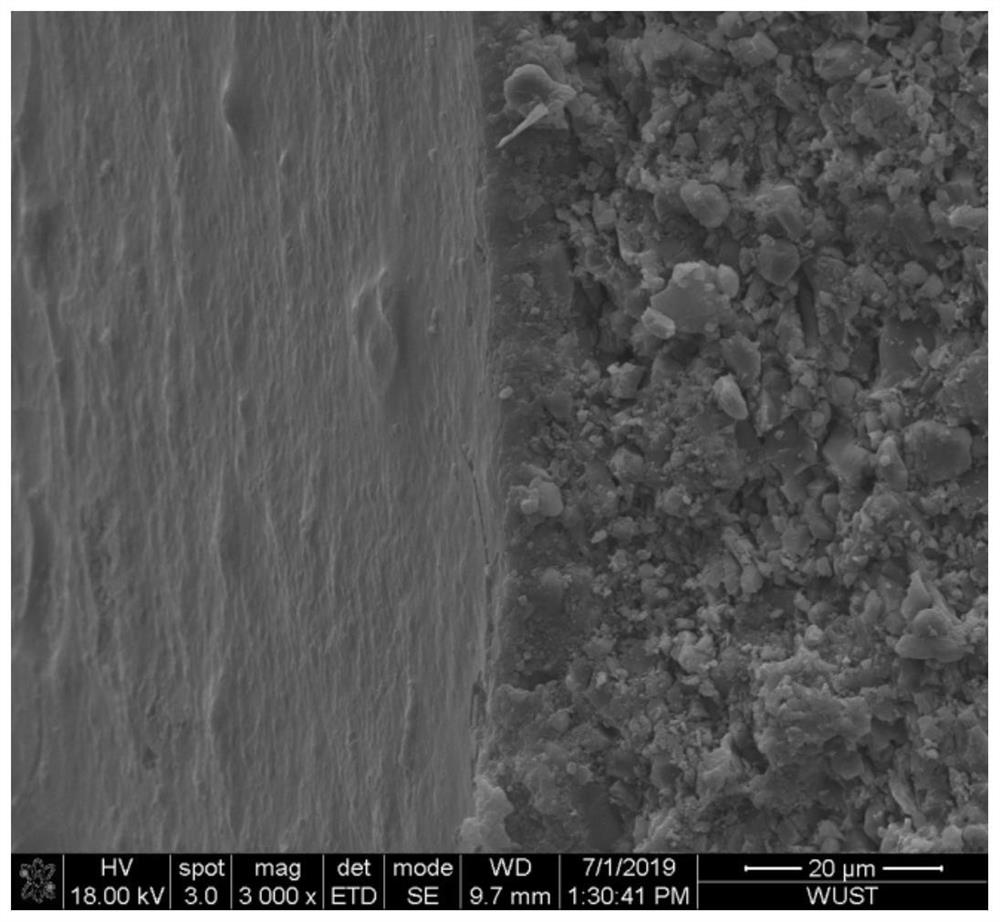

A technology of silicon dioxide and composite membrane, applied in the field of composite membrane, can solve the problems of low flux and poor hydrothermal stability of silicon dioxide membrane, and achieve the effects of easy batching, stable network structure and increased flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]The preparation method is performed in step (1) to step (3), and each step is explained.

[0057]Step (1): Preparation of large, small particle sol and precursor sol

[0058]1) The preparation process of large and small particle sol is as follows:

[0059]Process (1-1): 3 g of orthosilicate was added to 110 g of ethanol solution, and 1 g of deionized water and 3 g of concentrated hydrochloric acid were oscillated at room temperature for 3 h after mixing.

[0060]Process (1-2): After the ethane hydrolysis is hydrolyzed, 6 g of ni-niol zirconium continues to oscillate 12h;

[0061]Process (1-3): The above solution was transferred into a three flask to add a large amount of deionized water to 500 mL and an appropriate amount of hydrochloric acid was added to 2 or less, boiled for 8 h, and the total volume of the solution was maintained at 500 mL;

[0062]Procedure (1-4): Cool until the reaction was completed to room temperature. The prepared adhesive sol was divided into two alcohols, and two alum...

Embodiment 2

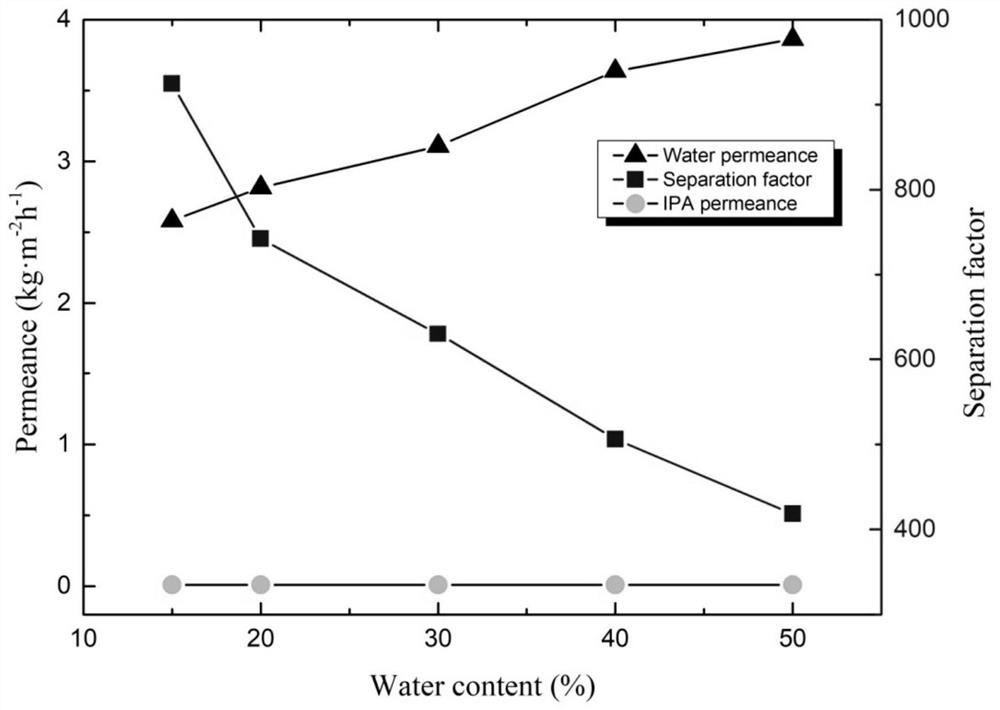

[0080]In this example, the film tube was soaked in a hydrochloride prepared to PH = 2 (± 0.2), and the film tube was removed, and the diaphragm is taken out, and the test is removed, and the test is subjected to the acid solution. , Repeat operation until the end of the immersion is 15 days. The operating temperature of the permeable vaporization performance was maintained at 75 ° C, and the aqueous content of the isopropyl alcohol solution to be separated was 15% by weight.

[0081]Figure 4 Under the hydrochloric acid treatment of the double silane precursor, the hydrochloric acid solution of pH = 2, the effect of different treatment time on its permeation vaporization performance. As can be seen from the figure, the flux of the membrane tube has gradually stabilized the change in the decline as the acid immersion time, and finally stabilizes the water content, and the water content of the permeate is also a slow increase. trend. The prepared silica composite membrane can remain stabl...

Embodiment 3

[0083]In this example, the monosilane (Btese) silica composite film is prepared, and the silane silica composite film in Example 1 is subjected to permeability.

[0084]The preparation step (1) to step (3) of this Example 3 is only that the difference from the first embodiment is only that

[0085]1) Preparation process of precursor sol: Process (1-5): Add Btese to anhydrous ethanol and add mixed solution of nitric acid and deionized water therein, and quench the reaction after reaction in an ice bath. Mono-transparent Btese sol; process (1-5) each substance molar ratio is: Btese: EtoH: HNO3: H2O = 1: 10: 0.1: 6.

[0086]Others are all identical, no longer educated.

[0087]In this Example 3, 5 sets of silica composite film tubes were prepared under the same conditions, respectively, respectively, made of silane (Btese / MTES) and single silane (Btese) as the precursor substance by sol gel method.

[0088]Figure 5 The permeation vaporification properties of the silica composite film prepared by do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com