Method for preparing organic fertilizer from coal-based solid waste

An organic fertilizer, coal-based technology, applied in the direction of fertilizer mixture, bio-organic part treatment, nitrogen fertilizer, etc., can solve the problems of polluting fragile environment, high maintenance cost of gangue dump, high cost enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

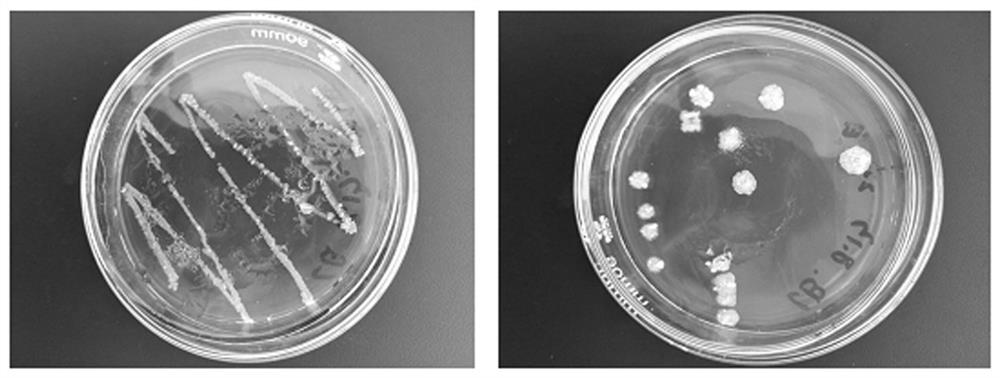

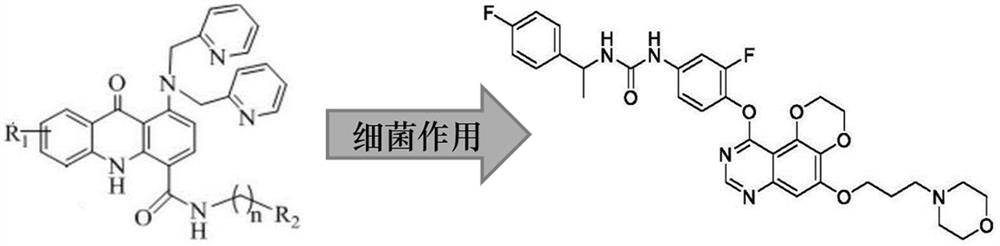

[0033]Crush the coal-based solid waste to less than 1.0 mm, and then grind it until the particle size is less than 0.125 mm. Take the ground coal-based solid waste and put it in a petri dish, add and mix according to the mass ratio of 100:2-8:8-20 Nutrients and tap water were used to cultivate at room temperature for 5 days to 30 days. The cultivated coal-based solid waste is taken out, soaked in water for 4 h-8 h according to the liquid-solid mass ratio of 1:2-5, and the water extract and water-extracted solid waste are obtained after solid-liquid separation, and the leachate is placed in Cultivate in solid medium at room temperature for 2 days to 4 days, and observe the growth morphology and development of the colony. To separate the colonies obtained above, first select a certain amount of colonies with a bacteria picker and draw a line in an aseptic operating table. The line drawing method can be linear or grid. Medium to 25 o C-35 o C culture for 2 days to 6 days. Acco...

Embodiment 2

[0035] Crush the coal-based solid waste to less than 1.0 mm, and then grind it until the particle size is less than 0.125 mm. Take the ground coal-based solid waste and put it in a petri dish, add and mix according to the mass ratio of 100:2-8:8-20 Nutrients and tap water were used to cultivate at room temperature for 5 days to 30 days. The cultivated coal-based solid waste is taken out, soaked in water for 4 h-8 h according to the liquid-solid mass ratio of 1:2-5, and the water extract and water-extracted solid waste are obtained after solid-liquid separation, and the leachate is placed in Cultivate in solid medium at room temperature for 2 days to 4 days, and observe the growth morphology and development of the colony. To separate the colonies obtained above, first select a certain amount of colonies with a bacteria picker and draw a line in an aseptic operating table. The line drawing method can be linear or grid. Medium to 25 o C-35 o C culture for 2 days to 6 days. Acc...

Embodiment 3

[0037] Crush the coal-based solid waste to less than 1.0 mm, and then grind it until the particle size is less than 0.125 mm. Take the ground coal-based solid waste and put it in a petri dish, add and mix according to the mass ratio of 100:2-8:8-20 Nutrients and tap water were used to cultivate at room temperature for 5 days to 30 days. The cultivated coal-based solid waste is taken out, soaked in water for 4 h-8 h according to the liquid-solid mass ratio of 1:2-5, and the water extract and water-extracted solid waste are obtained after solid-liquid separation, and the leachate is placed in Cultivate in solid medium at room temperature for 2 days to 4 days, and observe the growth morphology and development of the colony. To separate the colonies obtained above, first select a certain amount of colonies with a bacteria picker and draw a line in an aseptic operating table. The line drawing method can be linear or grid. Medium to 25 o C-35 o C culture for 2 days to 6 days. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com