A method for preparing a solid composite electrolyte membrane supported by a synchronous substrate

A technology of composite electrolyte membrane and solid electrolyte, which is applied in the manufacture of electrolyte batteries, electrolytes, non-aqueous electrolyte batteries, etc. It can solve the problems of uncontrollable electrolyte penetration effect, great difference in film forming mechanical properties, and damage to the safety performance of solid-state batteries. Achieve the effect of improving lithium guiding ability, good processing performance, uniform and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A preparation method of a solid composite electrolyte membrane supported by a synchronous substrate, comprising the following steps:

[0019] a. Ultra-high molecular weight or high-density polyolefin melt slurry is extruded to form a cast film;

[0020] b. Uniformly extruding the molten solid electrolyte slurry on the surface of the cast film at a temperature T1 to form a solid electrolyte coating to obtain a solid electrolyte coating-cast substrate;

[0021] c. Stretching the solid electrolyte coating-cast sheet substrate at a temperature T2 to obtain a film;

[0022] d. The stretched film is hot-pressed to control its thickness, and then cooled to obtain a solid composite electrolyte membrane.

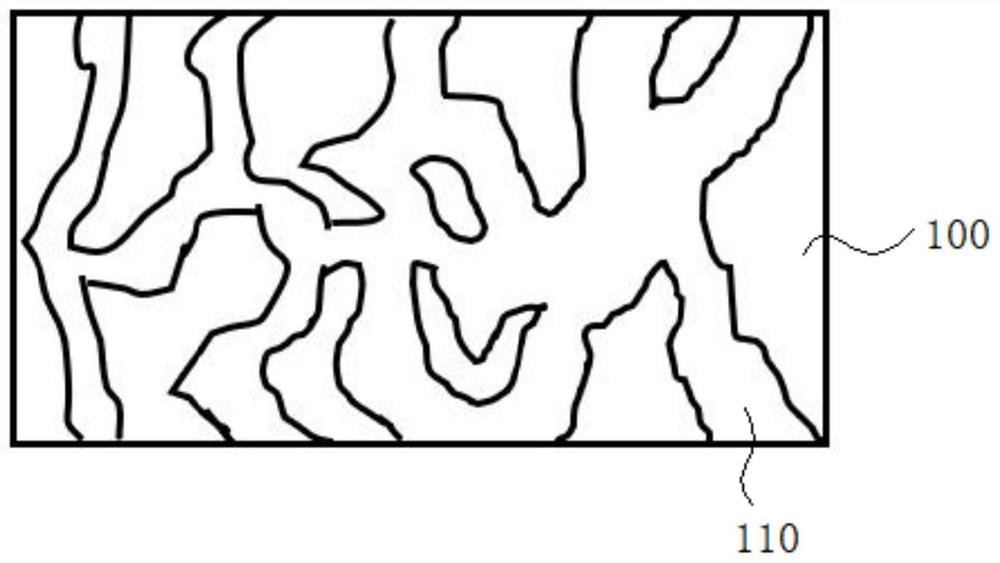

[0023] The present invention is to extrude and coat the molten solid electrolyte slurry on the polyolefin cast sheet to form a solid electrolyte coating-cast sheet substrate, which is then stretched, hot-pressed, and cooled in a heated state. figure 1 , to obtain a solid com...

Embodiment 1

[0056] The stretching method in this embodiment is stretching-impregnation simultaneous double-stretching, that is, as mentioned above, the process of stretching and reaming of the base material and infiltration and filling of the solid electrolyte material are not independent steps, but are carried out synchronously. The solid-state composite electrolyte membrane is based on the ratio of parts by mass, using 50 parts of polyethylene with a weight average molecular weight of 1.4 million to 1.6 million, 70 parts of polymer electrolyte, 30 parts of inorganic filler, and 5 parts of polymer interface modifier. 15 parts of lithium salt are obtained by melt mixing extrusion, stretching, and hot pressing; among them, the polymer electrolyte has a weight average molecular weight of 400,000, and polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) / weight average molecular weight 50,000 polypropylene carbonate (PPC) = 2:1; the inorganic filler is lithium lanthanum zirconium oxide parti...

Embodiment 2

[0058] The stretching method in this embodiment is stretching-dipping synchronous double stretching. The components and proportions of polyolefin substrate and solid electrolyte are the same as in Example 1. The stretching temperature of the simultaneous double stretching was 125° C., the transverse and longitudinal stretch ratio was 1.5, the longitudinal stretch ratio was 8 times, and the transverse stretch ratio was 12 times. The stretching rate was 100 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com