Graphene-like biochar for removing heavy metals and preparation method of graphene-like biochar

A biochar and graphene technology, applied in the preparation/purification of graphene and carbon, chemical instruments and methods, etc., can solve the problems of high production cost, low output, and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, a kind of preparation method of the graphene-like biochar that is used for heavy metal removal comprises the following steps:

[0035] a. Utilize the petals of magnolia flower as a biochar carbon source material, wash and dry the collected petals, and set aside;

[0036] b. The petal carbon source obtained in step a is placed in the cysteine aqueous solution, and the petal and the sulfur nitrogen compound are fully mixed according to the ratio of the mass ratio of the petal to the cysteine water as the carbon source being 2:1 Finally, place in a vacuum oven at 60°C and dry overnight to obtain a mixture;

[0037] c. placing the mixture obtained in step b in a quartz boat, and performing a pyrolysis reaction at 700° C. for 4 hours under an argon atmosphere to obtain a black solid product;

[0038] d. Put the black solid product obtained in step c into an aqueous solution of nitric acid with a concentration of 6 mol / L, and perform an acidifi...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, especially in that:

[0049] A preparation method for graphene-like biochar for heavy metal removal, comprising the following steps:

[0050] a. Utilize the petals of magnolia flower as a biochar carbon source material, wash and dry the collected petals, and set aside;

[0051] b. The petal carbon source obtained in step a is placed in the cysteine aqueous solution, and the petal and the sulfur nitrogen compound are fully mixed according to the mass ratio of the petal as the carbon source and the cysteine water as 1:1 Finally, place in a vacuum oven at 60°C and dry overnight to obtain a mixture;

[0052] c. placing the mixture obtained in step b in a quartz boat, and performing a pyrolysis reaction at 600° C. for 3 hours under an argon atmosphere to obtain a black solid product;

[0053] d. Put the black solid product obtained in step c into an aqueous nitric acid solution with a concentration of 5 mol / L, and ...

Embodiment 3

[0059] This embodiment is basically the same as the previous embodiment, and the special features are:

[0060] A preparation method for graphene-like biochar for heavy metal removal, comprising the following steps:

[0061] a. Utilize the petals of magnolia flower as a biochar carbon source material, wash and dry the collected petals, and set aside;

[0062] b. The petal carbon source obtained in step a is placed in the cysteine aqueous solution, and the petal and the sulfur nitrogen compound are fully mixed according to the ratio of the mass ratio of the petal to the cysteine water as the carbon source being 3:1 Finally, place in a vacuum oven at 60°C and dry overnight to obtain a mixture;

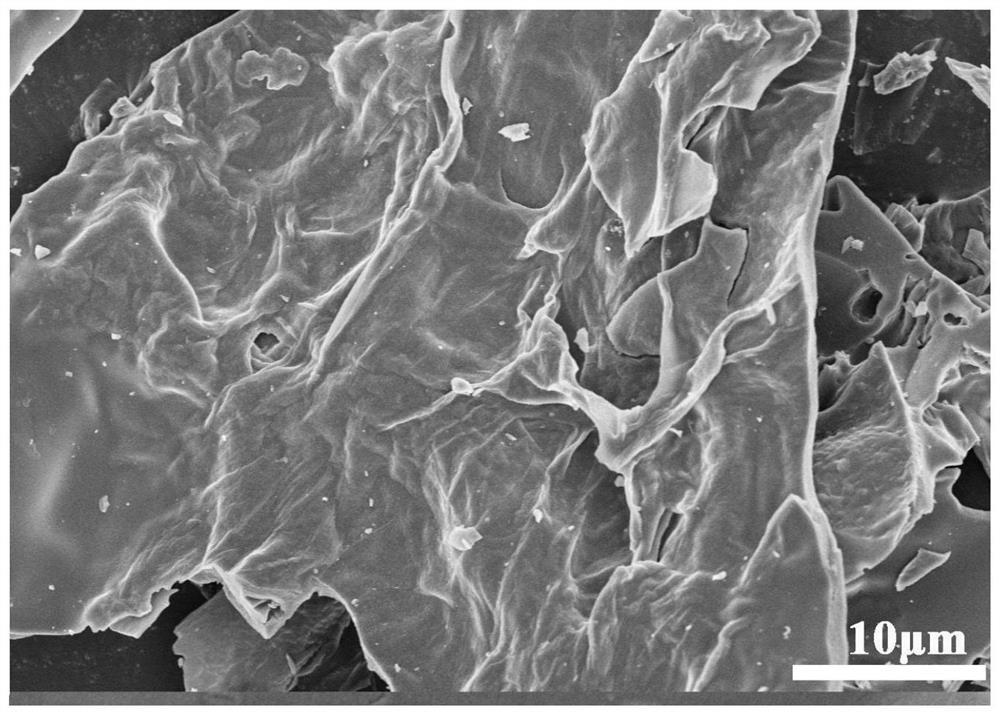

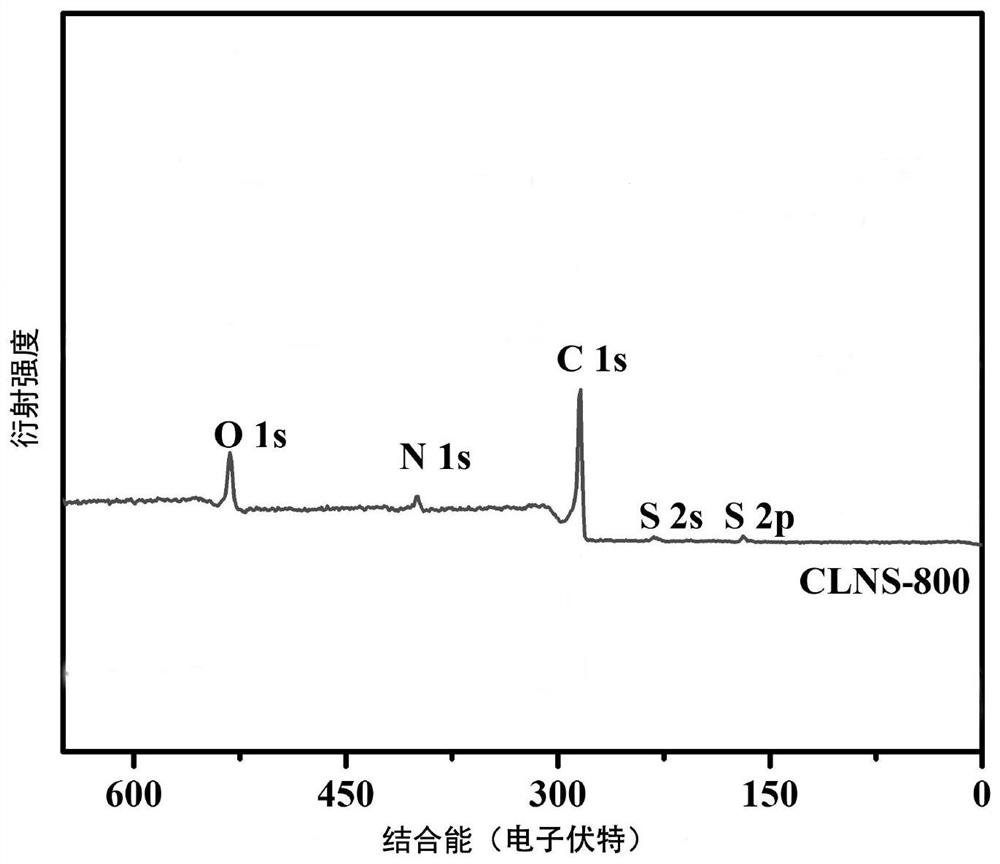

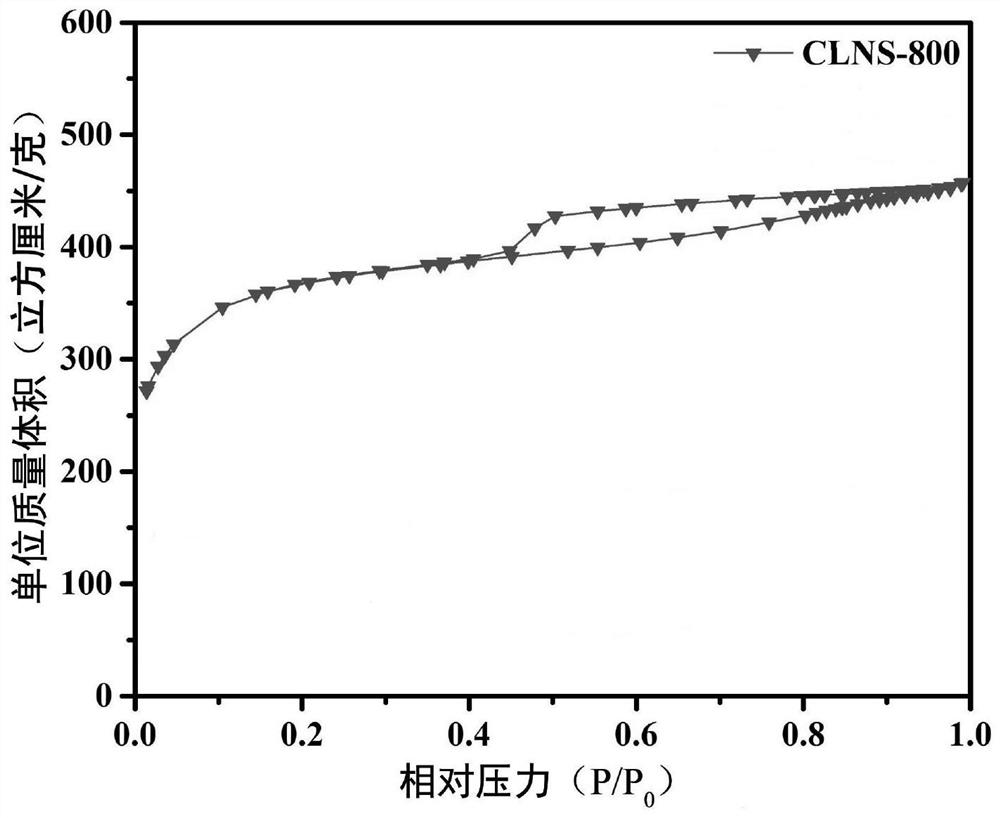

[0063] c. placing the mixture obtained in step b in a quartz boat, and performing a pyrolysis reaction at 800° C. for 5 hours under an argon atmosphere to obtain a black solid product;

[0064] d. Put the black solid product obtained in step c into an aqueous nitric acid solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com