A kind of preparation method of UHV composite insulator

A composite insulator and ultra-high voltage technology, applied in the field of preparation of ultra-high voltage composite insulators, can solve the problems of short service life, poor hydrophobicity, and reduced tensile strength, achieve excellent formability, improve aging resistance, reduce The effect of thermal degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

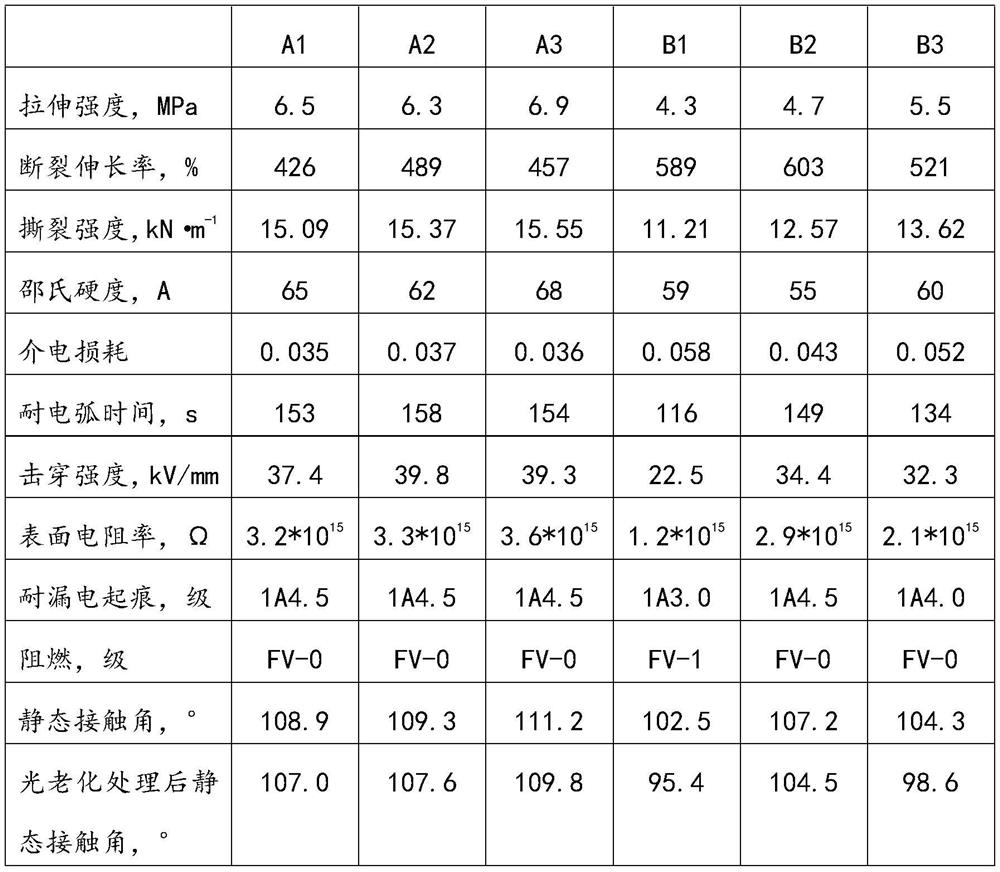

Examples

preparation example Construction

[0030] The preparation method of the UHV composite insulator of the present invention specifically comprises the following steps:

[0031] (1) Put methyl vinyl phenyl silicone rubber raw rubber, Mg-SiC compound and hydroxyl silicone oil in a kneader, knead at 80-120°C for 0.5-1h, then mix modified diatomaceous earth, cyclo Thin trisilazane, nano-ZnO, titanium dioxide, dispersant and silane coupling agent are put into the kneader, vacuumed for vacuum kneading, the vacuum degree is 0.05-0.26MPa, the temperature is 120-160°C, and kneading for 2-3h , to obtain the mixed rubber.

[0032] (2) Wrap the mixed rubber on an open mill, add a vulcanizing agent, thin it out, and release the sheet, then place the sheet on a flat vulcanizing machine for vulcanization and molding, and vulcanize for 10 at 160-180°C under a pressure of 10-12MPa. -12min, get silicone rubber material.

[0033] (3) Put the FRP mandrel into the pressure impregnation tank, turn on the vacuum pump, vacuumize, the v...

Embodiment 1

[0039] A kind of preparation method of silicone rubber material The preparation method specifically comprises the following steps:

[0040] (1) Put 100 parts of methyl vinyl phenyl silicone rubber raw rubber, 40 parts of Mg-SiC compound and 3 parts of hydroxyl silicone oil in a kneader, knead at 80°C for 1 hour, and then mix the modified diatomite 70 parts, 7 parts of cyclic trisilazane, 5 parts of nano-ZnO, 2 parts of titanium dioxide, 1.5 parts of dispersant and 1.5 parts of silane coupling agent were put into the kneader, vacuumed for vacuum kneading, the vacuum degree was 0.05MPa, The temperature was 160°C, and the mixture was kneaded for 3 hours to obtain a mixed rubber.

[0041] (2) Wrap the mixed rubber on an open mill, add 3 parts of vulcanizing agent phenol formaldehyde resin, thin it out, and release the sheet, then place the sheet on a flat vulcanizing machine for vulcanization and molding, and vulcanize at 160°C and 12MPa pressure After 10 minutes, the silicone ru...

Embodiment 2

[0047] A kind of preparation method of silicone rubber material specifically comprises the following steps:

[0048] (1) Put 100 parts of methyl vinyl phenyl silicone rubber raw rubber, 80 parts of Mg-SiC compound and 5 parts of hydroxyl silicone oil in a kneader, knead at 120°C for 0.5h, and then mix the modified diatom Put 50 parts of soil, 4 parts of cyclic trisilazane, 8 parts of nano-ZnO, 5 parts of titanium dioxide, 3 parts of dispersant and 4 parts of silane coupling agent into the kneader, vacuumize and knead with a vacuum degree of 0.26MPa , the temperature was 120°C, and the mixture was kneaded for 2 hours to obtain a mixed rubber.

[0049] (2) Wrap the mixed rubber on an open mill, add 1 part of vulcanizing agent phenol formaldehyde resin, thin it out, and release the sheet, then put the sheet material on a flat vulcanizing machine for vulcanization molding, and vulcanize at 180°C and 10MPa pressure After 12 minutes, the silicone rubber material A2 was obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com