Preparation method and application of electrochemical sensor based on tyrosinase nanocapsule

A tyrosinase, nanocapsule technology, applied in the field of biosensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

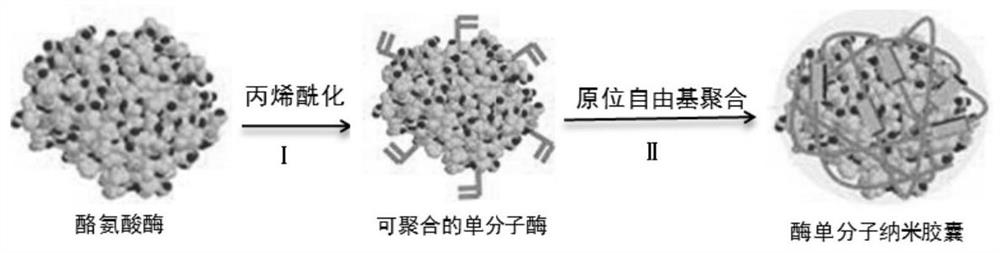

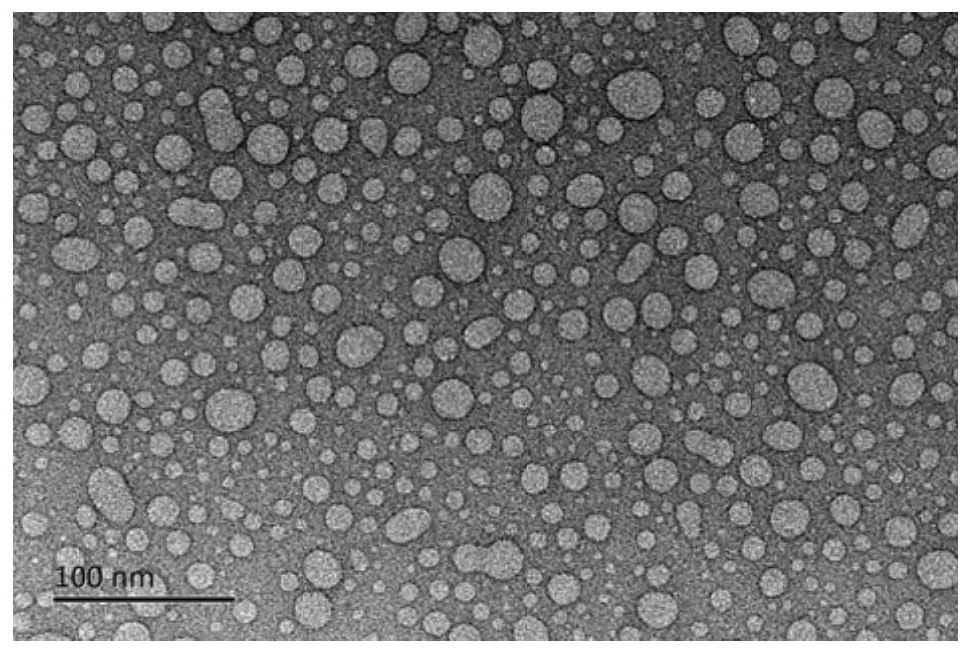

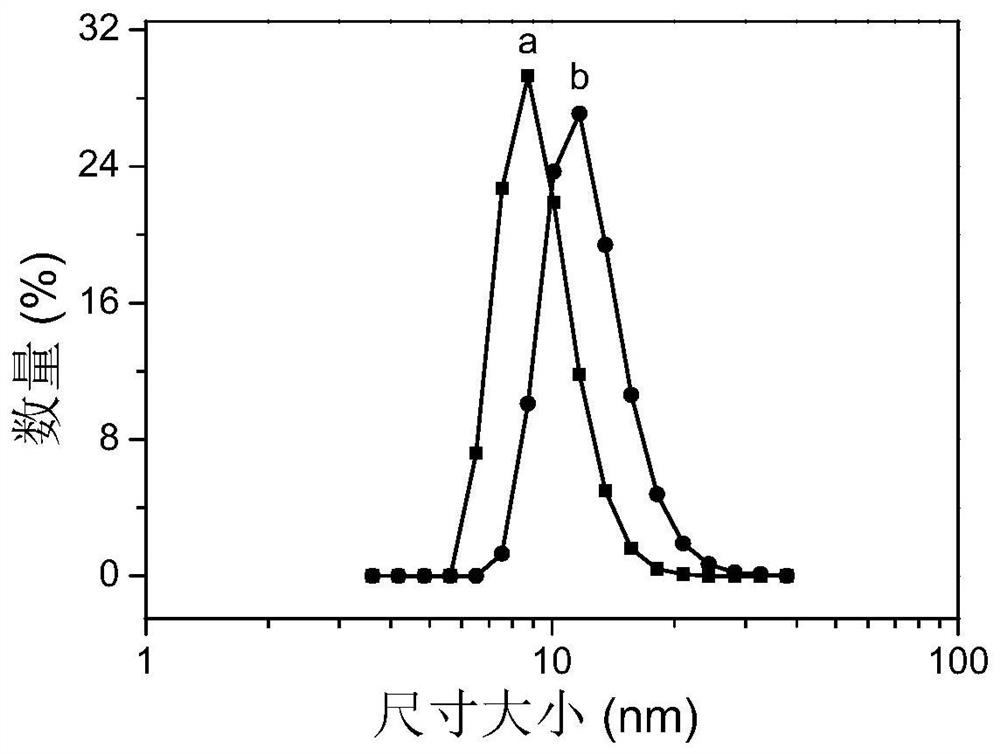

[0052] Preparation and Characterization of Tyrosinase Nanocapsules

[0053] Firstly, the alkenyl group is connected to the surface of the enzyme molecule by adsorption, covalent crosslinking, etc. to make it a polymerizable unimolecular enzyme form, and then a thin layer of polymer is formed on the enzyme surface by in situ free radical polymerization. Shell, that is, the formation of enzyme single-molecule nanocapsules.

[0054] (a) Surface modification of tyrosinase

[0055] Dissolve tyrosinase (Tyr) in disodium hydrogen phosphate-sodium dihydrogen phosphate buffer (50 mM, pH 7.0) at a concentration of 5 mg / mL; dissolve N-acryloyloxysuccinimide (NAS) In dimethyl sulfoxide (DMSO), the concentration was 10 mg / mL.

[0056] Take 20μL 10mg / mL NAS and slowly add to 200μL 5mg mL -1 The tyrosinase solution was reacted at 4 °C for 2 h. The reacted solution was transferred to a dialysis tube with a molecular weight cut-off of 12kDa, and dialyzed in disodium hydrogen phosphate-sodi...

Embodiment 2

[0064] Activity comparison of tyrosinase and surface-modified tyrosinase

[0065] Fabrication of electrochemical enzyme sensors

[0066] (1) Polish the surface of the glassy carbon electrode with aluminum oxide powder with a particle size of 1 μm, 0.3 μm, and 0.05 μm, and then repeatedly ultrasonically clean it in absolute ethanol and deionized water, and then clean the electrode surface with high-purity nitrogen gas. Blow dry and set aside. Put in 1mmol L -1 The cyclic voltammetry curve was scanned between -0.1 and +0.6V in the potassium ferricyanide / potassium ferrocyanide solution (molar ratio 1:1). The redox peak potential difference of the curve is less than 70mV, indicating that the redox reaction on the surface of the glassy carbon electrode is a completely reversible reaction, and the electrode polishing is in good condition, and the next experiment can be carried out.

[0067] (2) The biocompatible film-forming agent chitosan (its film-forming ability and adhesion i...

Embodiment 3

[0074] Thermostability of Tyrosinase Nanocapsules

[0075] In the tyrosinase nanocapsule solution that obtains in embodiment 1, add film-forming agent chitosan, fully mix, the composition of final dispersion liquid is that the concentration of tyrosinase nanocapsule is 2.5mg mL-1 ;Chitosan concentration is 1.5mg mL -1 , 5 μL of the final dispersion was dropped onto the surface of the glassy carbon electrode, and left to dry slowly at room temperature to obtain a homogeneous tyrosinase nanocapsule-chitosan electrode (nTyr-Chi / GCE).

[0076] Prepare Tyr-Chi and nTyr-Chi electrodes with free tyrosinase and tyrosinase nanocapsules. At room temperature, add 4 μL of 1 mM bisphenol A standard solution continuously (every 50 s) to the Tyr-Chi or nTyr electrode. In the detection solution of the three-electrode system composed of -Chi electrodes in 8mL phosphate buffer solution, the constant potential scanning was carried out under the condition of the working potential of -0.04V, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com