Photoresist material for micro-nano processing as well as preparation and application thereof

A technology of photoresist and micro-nano structure, which is applied in the direction of photosensitive materials used for optomechanical equipment, technology for producing decorative surface effects, optomechanical equipment, etc., which can solve the incompatibility of photolithography technology and low resolution, etc. problem, to achieve the effect of widening the selection range, simple preparation method and various types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

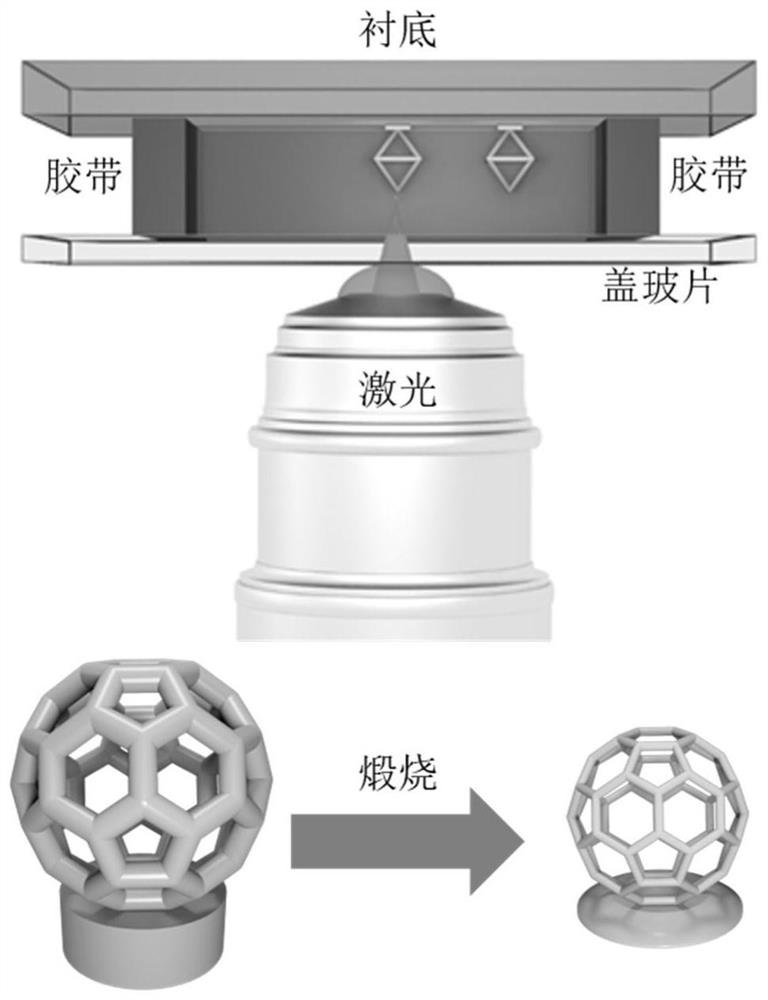

[0052] The present invention also provides the preparation method of described photoresist material, comprises the steps:

[0053] (1) Mix photosensitive resin monomer, organic acid and metal-organic framework material evenly to form solution A;

[0054] (2) Under the condition of avoiding light, add a photoinitiator into the solution A and stir evenly to obtain the photoresist material.

[0055] The good mutual solubility of metal organic framework materials and photosensitive resin monomers is very important for the preparation of three-dimensional metal oxide micro-nano structures by laser direct writing lithography. In the experiment of the present invention, it was found that the type of solvent was not suitable, or the dissolution time was not enough to cause the metal-organic framework When the material cannot be dissolved well, it cannot be formed by direct writing in subsequent laser direct writing, and an ideal three-dimensional structure cannot be obtained. If the ...

Embodiment 1

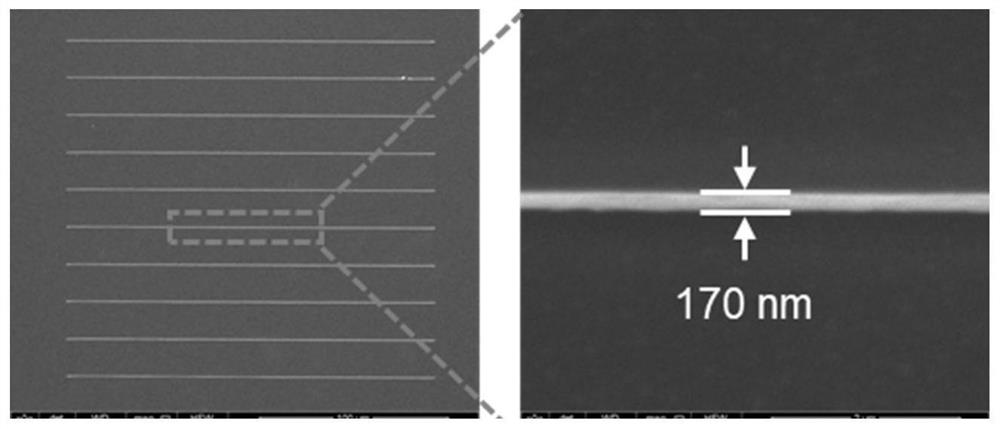

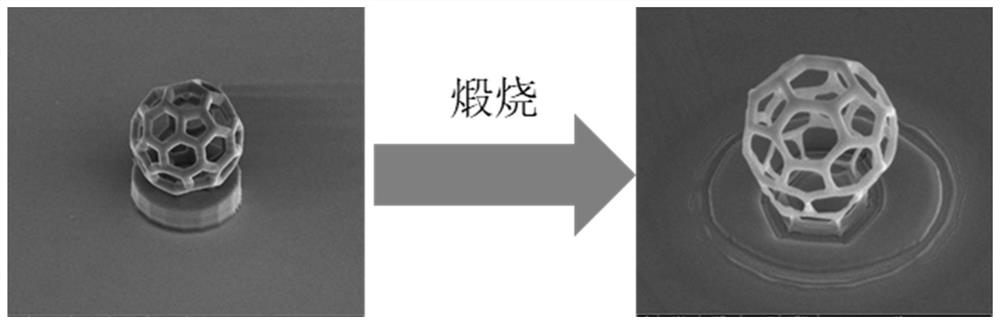

[0074] Dissolve 200 mg of ZIF-8 in 600 μL of acrylic acid and 500 μL of di(trimethylolpropane) tetraacrylic acid, and ultrasonicate in a water bath for 2 hours to obtain a uniform solution, then add 15 mg of photoinitiator benzil, photosensitizer 2-benzyl- 15 mg of 2-(dimethylamino)-4-morpholinobutaphenone was stirred with a magnetic stirrer for 30 min to obtain the photoresist, and the photoresist was dropped drop by drop on the quartz glass substrate with an interlayer. The developed femtosecond laser processing system additively manufactured a three-dimensional structure, then developed it in acrylic acid for five minutes, placed it in a diluent for five minutes, and dried it naturally to obtain a polymer with a three-dimensional micro-nano structure. The polymer with the three-dimensional micro-nano structure is placed in a small RTP annealing furnace, the heating rate is controlled at 5°C / min, under the oxygen flow, it is calcined at 550°C for 1 hour, and naturally cooled ...

Embodiment 2

[0078] Dissolve 50 mg of ZIF-67 in 600 μL of acrylic acid and 500 μL of bis(trimethylolpropane) tetraacrylic acid, and ultrasonicate for 2 hours in a water bath to obtain a uniform solution, then add 15 mg of photoinitiator benzil, photosensitizer 2-benzyl- 15 mg of 2-(dimethylamino)-4-morpholinobutaphenone was stirred with a magnetic stirrer for 30 min to obtain the photoresist, and the photoresist was dropped drop by drop on the quartz glass substrate with an interlayer. The developed femtosecond laser processing system additively manufactured a three-dimensional structure, then developed it in acrylic acid for five minutes, placed it in a diluent for five minutes, and dried it naturally to obtain a polymer with a three-dimensional micro-nano structure. The polymer with the three-dimensional micro-nano structure is placed in a small RTP annealing furnace, the heating rate is controlled at 5°C / min, under the oxygen flow, calcined at 600°C for 1 hour, and naturally cooled to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com