Preparation method of nanometer calcium carbonate used for filling of hard PVC

A technology of nano-calcium carbonate and calcium carbonate, which is applied in the direction of nanotechnology, calcium carbonate/strontium/barium, and nanotechnology for materials and surface science, and can solve the problem of yellowing of PVC filled with nano-calcium carbonate and poor dispersion of modifiers. Uniformity, product yellowing and other problems, to achieve the effect of enhancing dispersion and fluidity, maintaining whiteness and stability, slowing down decomposition and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

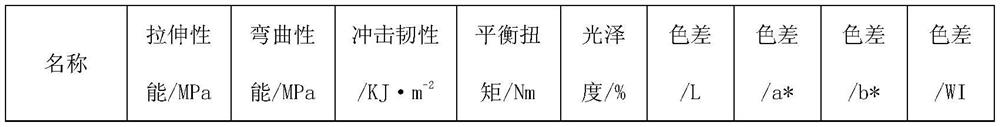

Examples

Embodiment 1

[0033] A preparation method for filling the nano-calcium carbonate of rigid PVC, comprising the following steps:

[0034] S1: Limestone with a mass content of 0.3% magnesium carbonate is calcined at 1000°C to obtain quicklime, and the quicklime and water are digested at a mass ratio of 1:5 to obtain Ca(OH) 2 , sieve and stand still, and then configure Ca(OH) with a solid content of 12% 2 suspension;

[0035] S2: To Ca(OH) 2 A mixture of 0.3% calcium carbonate on a dry basis mass of sucrose and glucose was added to the suspension as a crystal form control agent, and CO 2 The carbonation reaction is carried out with a mixed gas with a concentration of 20%, and the CO is controlled 2 The flow rate of the mixed gas is 0.02m 2 / h, the reaction temperature is 40°C, and the stirring speed is 500r / min; when the reaction suspension pH=10.0, stop feeding CO 2 ;

[0036] S3: carry out surface modification to the suspension, add the sodium stearate solution that the mass concentrati...

Embodiment 2

[0039]A preparation method for filling the nano-calcium carbonate of rigid PVC, comprising the following steps:

[0040] S1: Limestone with a mass content of 0.2% magnesium carbonate is calcined at 1100°C to obtain quicklime, and the quicklime and water are digested at a mass ratio of 1:7 to obtain Ca(OH) 2 , sieve and let it stand, and then configure it into Ca(OH) with a solid content of 9%. 2 suspension;

[0041] S2: To Ca(OH) 2 Add 0.4% sucrose on a dry basis of calcium carbonate as a crystal form control agent to the suspension, and feed CO 2 The mixed gas with a concentration of 40% is used for carbonation reaction to control CO 2 The flow rate of the mixed gas is 0.01m 2 / h, the reaction temperature is 30°C, and the stirring speed is 800r / min; when the reaction suspension pH=8.5, stop feeding CO 2 ;

[0042] S3: Carry out surface modification to suspension, add the sodium stearate solution that the mass concentration of 40% of calcium carbonate dry basis mass is 5...

Embodiment 3

[0045] A preparation method for filling the nano-calcium carbonate of rigid PVC, comprising the following steps:

[0046] S1: Limestone with a mass content of 0.1% magnesium carbonate is calcined at 1200°C to obtain quicklime, and the quicklime and water are digested at a mass ratio of 1:10 to obtain Ca(OH) 2 , sieve and let it stand, and then configure it into Ca(OH) with a solid content of 6.0%. 2 suspension;

[0047] S2: To Ca(OH) 2 Add 0.5% maltose on a dry basis of calcium carbonate to the suspension as a control agent, and feed CO 2 The mixed gas with a concentration of 30% carries out carbonation reaction and controls CO 2 The flow rate of mixed gas is 0.005m 2 / h, the reaction temperature is 35°C, and the stirring speed is 1000r / min; when the reaction suspension pH=9.2, stop feeding CO 2 ;

[0048] S3: carry out surface modification to the suspension, add the sodium stearate solution that the mass concentration of 50% of calcium carbonate dry basis mass is 70% to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com