Manganese-zinc power ferrite material and preparation method thereof

A ferrite material and power technology, which is applied in the field of magnetic materials to achieve the effects of reducing residual loss, increasing cut-off frequency and high saturation magnetic induction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045]

[0046] The preparation method of manganese zinc power ferrite material of the present invention comprises the steps:

[0047] (1), put main component into ball mill and carry out ball milling and mixing, once ball milling 30-60min, obtain mixed powder;

[0048] (2), the mixed powder is placed in a horse boiling furnace to keep warm, and pre-fired to obtain the pre-fired powder;

[0049] (3) After pulverizing the calcined powder, carry out secondary ball milling, and put it into a grinder, add auxiliary components and pure water for sand milling at the same time, and control the particle size at 1-2 μm;

[0050] (4), drying the slurry after the sanding in step (3), and adding polyvinyl alcohol to granulate, and pressing after drying to obtain a molded blank;

[0051] (5) Put the formed blank into a sintering furnace with atmosphere adjustment, and sinter it under the atmosphere of nitrogen and oxygen.

[0052] Wherein, in step (1), the main components include 73-74...

Embodiment 1

[0061] The preparation method of the manganese zinc power ferrite material of the present embodiment comprises the following steps:

[0062] (1), the Fe of 73.34wt% 2 o 3 , 3.30wt% of ZnO and the balance of MnO are put into a ball mill for ball milling and mixing, once ball milling for 30min, to obtain a mixed powder;

[0063] (2), place the mixed powder in a horse boiling furnace at 900°C, heat it for 1 hour to pre-burn, and obtain the pre-burned powder;

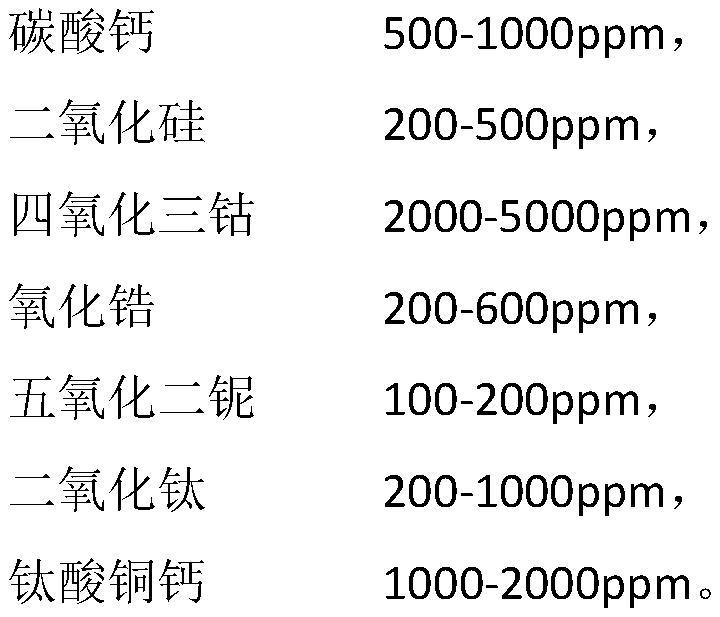

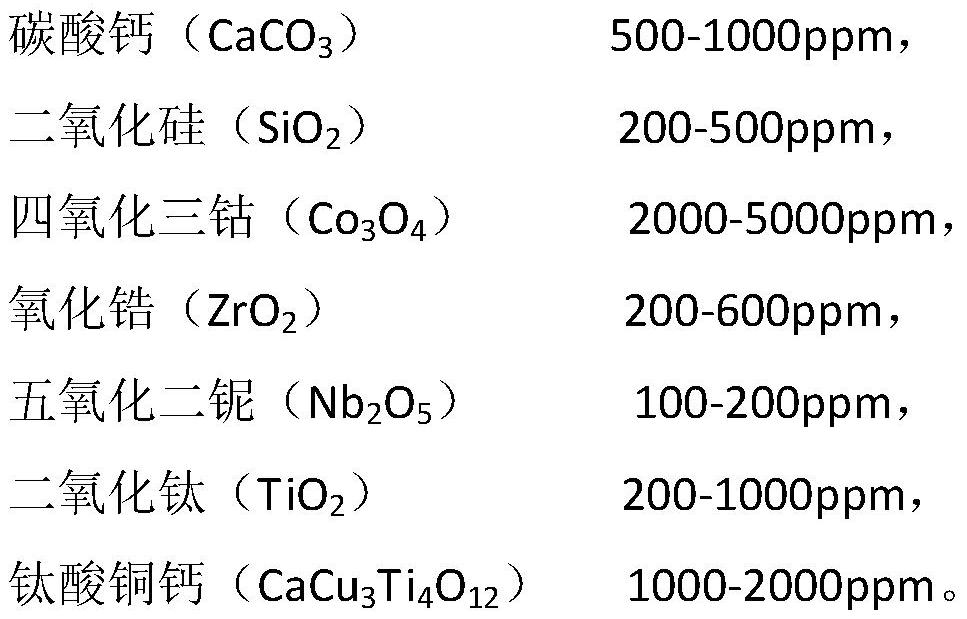

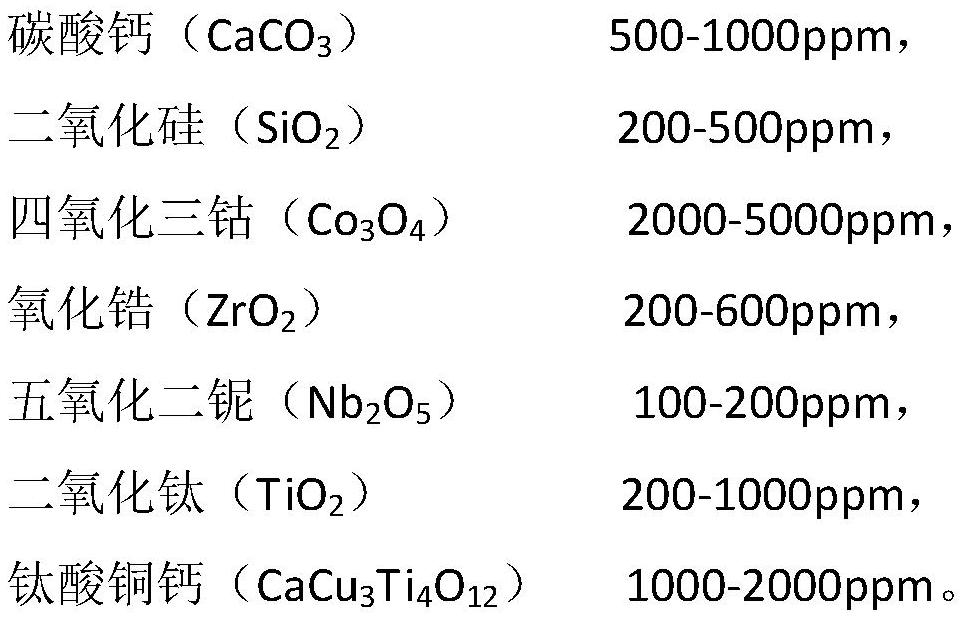

[0064] (3) Secondary ball milling for 60 minutes after the calcined powder is pulverized, and put into a grinder, and simultaneously add auxiliary components (as shown in Table 1) and pure water for sand milling, and the particle size is controlled to be 1 μm;

[0065] (4), drying the slurry after sanding in step (3), adding 15wt% polyvinyl alcohol (PVA) to granulate, drying at 250°C and then pressing to form, so as to obtain a molded blank;

[0066] (5), the molded blank is put into the sintering furnace with atmosphere...

Embodiment 2

[0072] The preparation process and main components are the same as in Example 1, and the changed additive (subcomponent) content is listed in Table 1. The test conditions are the same as in Example 1, and the test results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com