Integrated method for purifying rare earth metal gadolinium and preparing gadolinium oxide nano material by arc plasma method

An arc plasma and rare earth metal technology, which is applied in the preparation/treatment of rare earth metal oxides/hydroxides, rare earth metal compounds, lanthanide oxides/hydroxides, etc., can solve the problem of long operation time and product purity. Insufficient, long process flow and other problems, to achieve the effect of low production cost, good purification effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

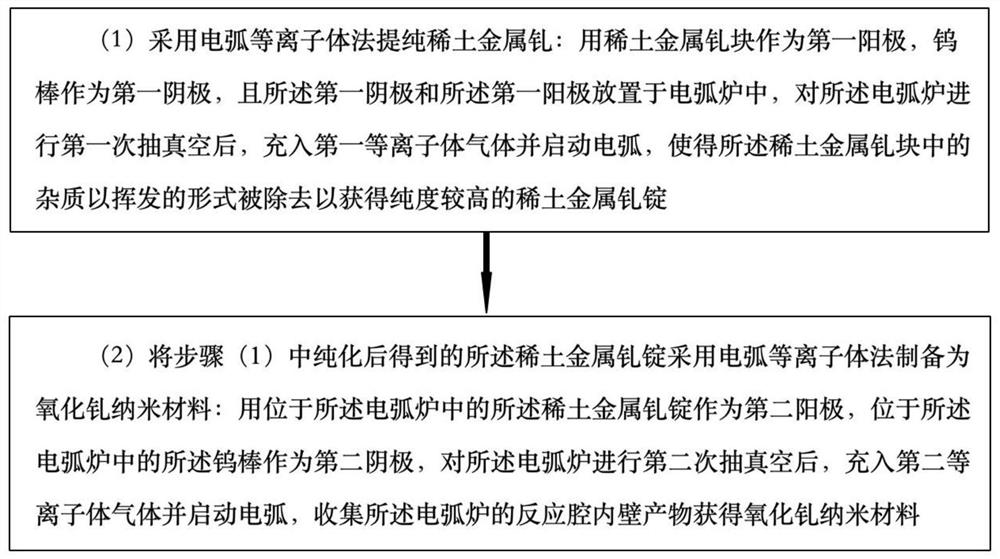

[0062] An arc plasma method for purifying rare earth metal gadolinium and preparing a method for integrating gadolinium oxide nanomaterials, the specific process is as follows:

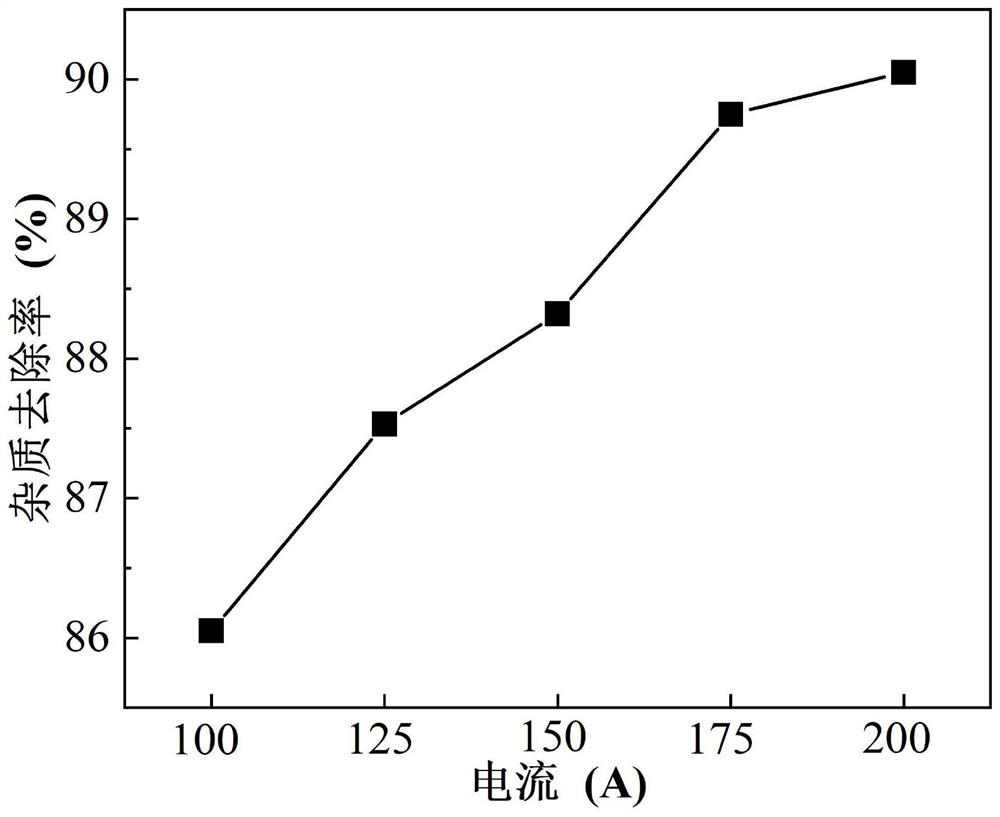

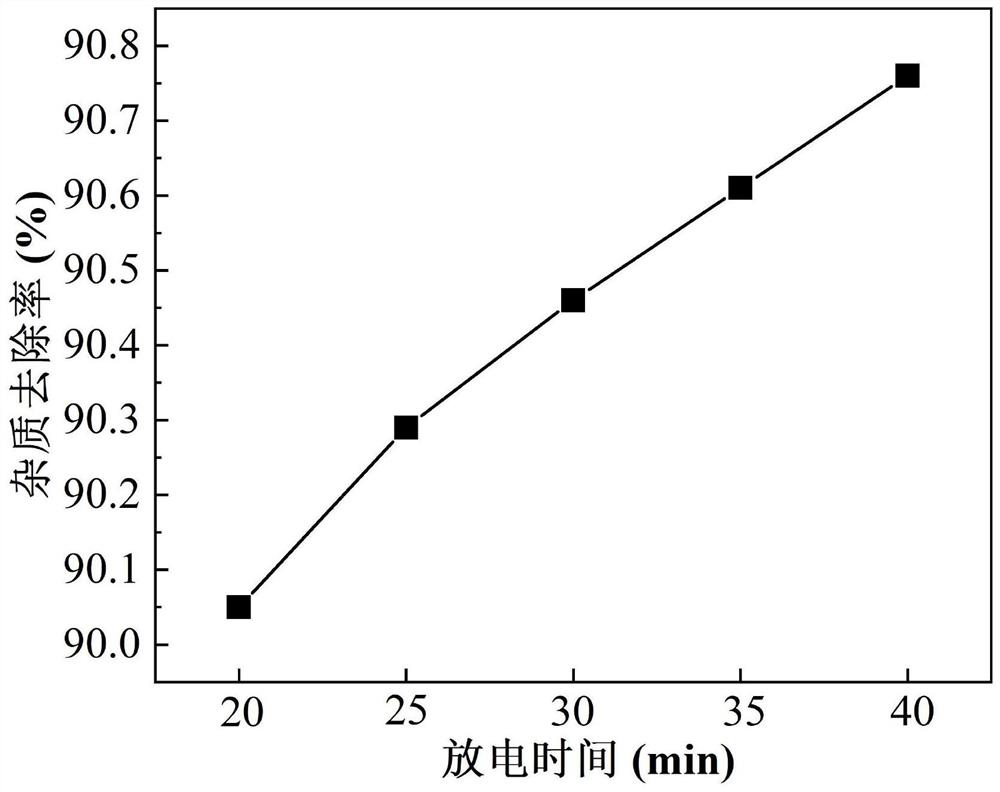

[0063] Step (1), using rare earth metal gadolinium block as the first anode (mass about 20g), tungsten rod as the first cathode, the first cathode and the first anode are vertically placed in the electric arc furnace (such as vertically along the horizontal The vertical direction of the direction), and the distance is 8mm. After the electric arc furnace is evacuated, it is filled with 50kPa of argon (Ar), starts the arc, adjusts the current to 100A and conducts plasma melting for 20min. After the melting is completed, the rare earth metal gadolinium ingot is obtained. The purity was tested by inductively coupled plasma mass spectrometry (ICP-MS).

[0064]In step (2), the rare earth metal gadolinium ingot obtained in the above step (1) is prepared into a gadolinium oxide nanomaterial by an arc plasma m...

Embodiment 2

[0066] An arc plasma method for purifying rare earth metal gadolinium and preparing a method for integrating gadolinium oxide nanomaterials, the specific process is as follows:

[0067] Step (1), using a rare earth metal gadolinium block as the first anode (mass about 20g), a tungsten rod as the first cathode, the first cathode and the first anode are placed vertically in the electric arc furnace, and the distance is 8mm, After the electric arc furnace was evacuated, it was filled with argon gas of 50kPa, the arc was started, and the current was adjusted to 125A for plasma smelting for 20min. ) for purity testing.

[0068] In step (2), the rare earth metal gadolinium ingot obtained in the above step (1) is prepared into a gadolinium oxide nanomaterial by an arc plasma method: using the rare earth gadolinium ingot as a second anode, and the tungsten rod as a second cathode, The second cathode and the second anode are vertically located in the electric arc furnace, and the dist...

Embodiment 3

[0070] An arc plasma method for purifying rare earth metal gadolinium and preparing a method for integrating gadolinium oxide nanomaterials, the specific process is as follows:

[0071] Step (1), using a rare earth metal gadolinium block as the first anode (mass about 20g), a tungsten rod as the first cathode, the first cathode and the first anode are placed vertically in the electric arc furnace, and the distance is 8mm, After the electric arc furnace was evacuated, it was filled with argon gas of 50kPa, the arc was started, and the current was adjusted to 150A for plasma smelting for 20min. ) for purity testing.

[0072] In step (2), the rare earth metal gadolinium ingot obtained in the above step (1) is prepared into a gadolinium oxide nanomaterial by an arc plasma method: using the rare earth gadolinium ingot as a second anode, and the tungsten rod as a second cathode, The second cathode and the second anode are vertically located in the electric arc furnace, and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com