Fe2O3-loaded Al2O3/SiO2@TiO2 porous core-shell sphere adsorbent as well as preparation method and application thereof

A porous core and adsorbent technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of adsorbents such as limited desulfurization and denitrification functions, inability to meet practical applications, and increased specific surface area, so as to improve adsorption capacity, Effect of reducing resistance and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

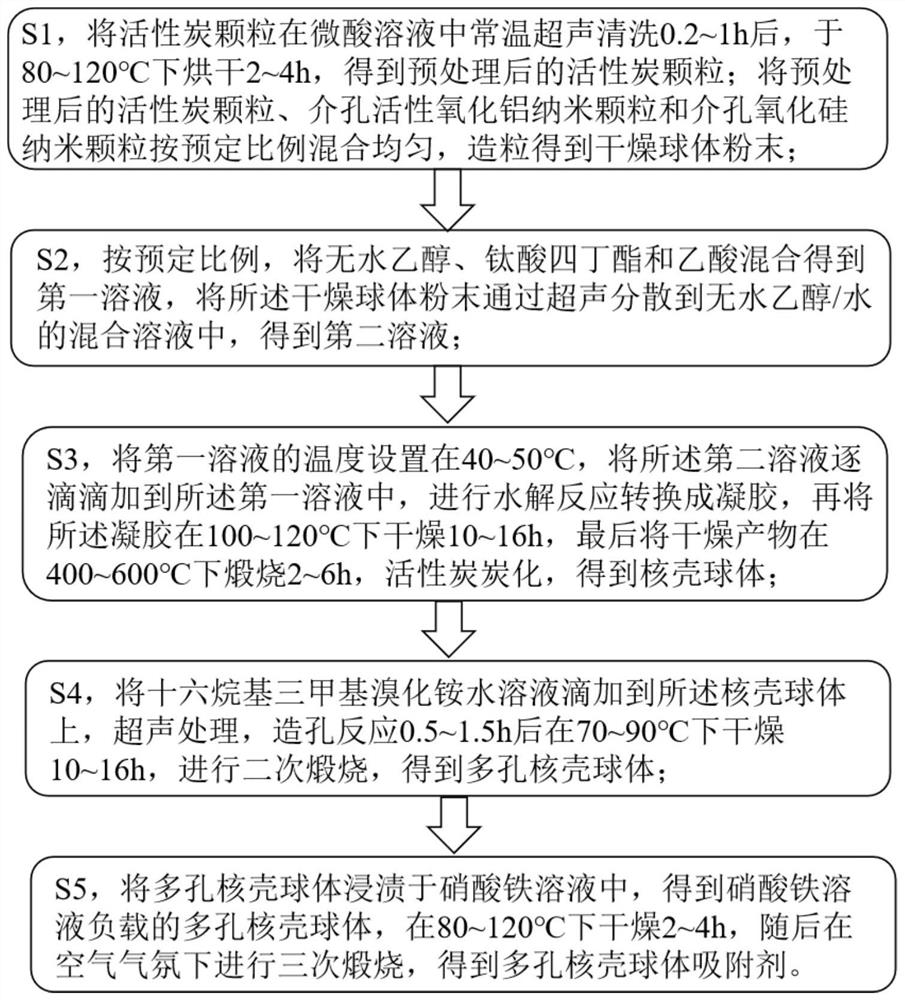

[0033] see figure 1 As shown, the present invention provides a Fe 2 o 3 load Al 2 o 3 / SiO 2 @TiO 2 The preparation method of porous core-shell spherical adsorbent comprises the following steps:

[0034] S1, the activated carbon particles are ultrasonically cleaned in a slightly acidic solution at room temperature for 0.2 to 1 hour, and then dried at 80 to 120°C for 2 to 4 hours to obtain pretreated activated carbon particles; pretreated activated carbon particles, mesoporous active oxidation Aluminum nanoparticles and mesoporous silica nanoparticles are mixed evenly according to a predetermined ratio, and granulated to obtain dry spherical powder with uniform particle size;

[0035] S2, mixing absolute ethanol, tetrabutyl titanate and acetic acid according to a predetermined ratio to obtain a first solution, and dispersing the dry spherical powder into a mixed solution of absolute ethanol / water by ultrasonic to obtain a second solution;

[0036] S3, setting the tempera...

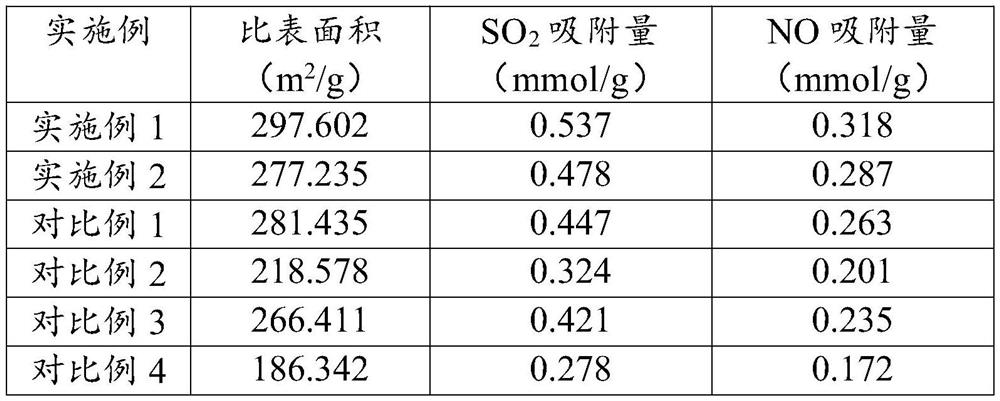

Embodiment 1

[0047] Embodiment 1 of the present invention provides a kind of Fe 2 o 3 load Al 2 o 3 / SiO 2 @TiO 2 The preparation method of porous core-shell spherical adsorbent comprises the following steps:

[0048] S1, the activated carbon particles were placed in a slightly acidic solution with a pH value of 6 and ultrasonically cleaned at room temperature for 0.5 h, then dried at 100°C for 3 h to obtain pretreated activated carbon particles; the pretreated activated carbon particles, mesoporous Activated alumina nanoparticles and mesoporous silica nanoparticles are mixed evenly at a mass ratio of 0.2:1:0.3, and dried spherical powder with uniform particle size is prepared through an integrated granulation dryer, and the diameter of the sphere is 0.5-2mm.

[0049] S2, mix 30mL of absolute ethanol, 10mL of tetrabutyl titanate and 5mL of acetic acid, adjust the pH value to 4 to obtain the first solution, and disperse the dried sphere powder into absolute ethanol / water (20mL: 2mL) by...

Embodiment 2

[0054] The difference from Example 1 is that the molar ratio of the dry sphere powder to the titanium in the tetrabutyl titanate (core / shell molar ratio) is 1.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com