Graphene smoke adsorption material for reducing harmful ingredients in cigarette smoke as well as preparation method and application thereof

A technology for adsorbing materials and harmful components, applied in the field of graphene flue gas adsorbing materials and preparation thereof, can solve problems such as unfavorable suction, affecting suction resistance, phenol reduction rate needs to be improved, etc., and achieves simple and easy operation and low cost in the preparation process. Inexpensive, adjustable aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

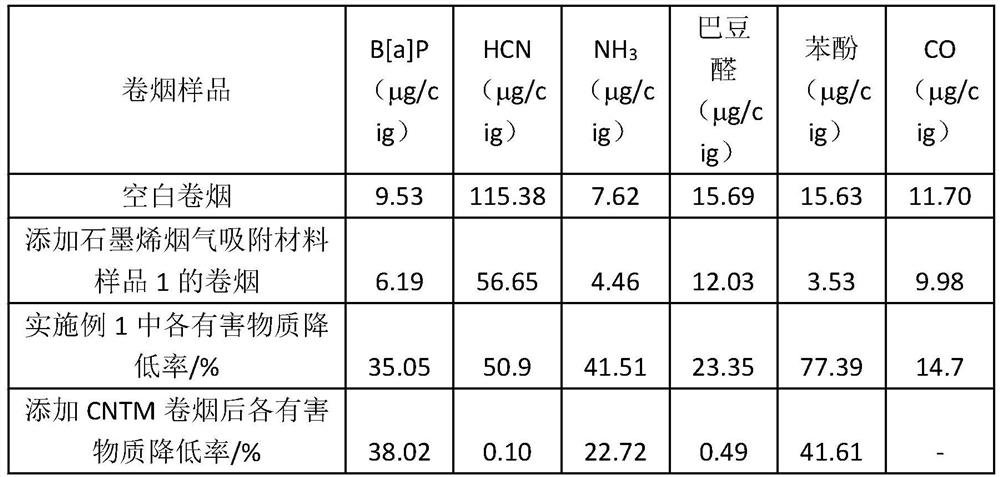

Embodiment 1

[0030] This embodiment is the preparation of graphene flue gas adsorption material sample 1, comprising the following steps:

[0031] (1) Add flake graphite into a single-necked flask equipped with a hydrochloric acid-hydrofluoric acid mixture (volume ratio of 1:0.5) and stir for 3 hours, separate solid from liquid, and obtain pretreated graphite after washing and drying. (100g / L) and potassium persulfate (100g / L) concentrated sulfuric acid to oxidize and dehydrate the pre-treated graphite, stir at 80°C for 6h, separate solid from liquid, and obtain pre-oxidized graphite after washing and drying. The mass ratio of sulfuric acid to pretreated graphite is 0.5:1; add preoxidized graphite, sodium nitrate, and potassium permanganate in sequence to concentrated sulfuric acid, and then place it in a water bath at 35°C for 9 hours, where concentrated sulfuric acid and preoxidized The mass ratio of graphite is 1:1, and the graphite of preoxidation: sodium nitrate: the mass ratio of pot...

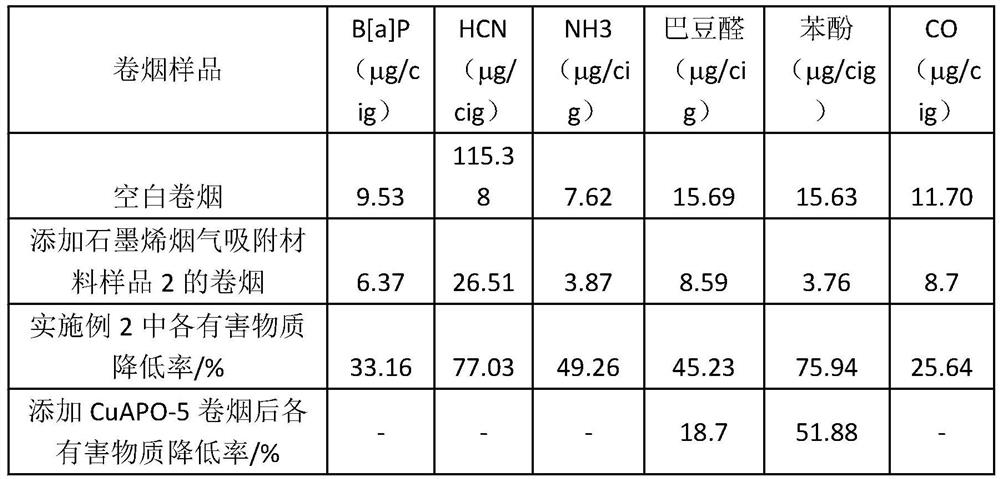

Embodiment 2

[0037] This embodiment is the preparation of graphene flue gas adsorption material sample 2, comprising the following steps:

[0038] (1) Add flake graphite into a single-necked flask equipped with hydrochloric acid-hydrofluoric acid mixture (volume ratio 1:1) and stir for 4 hours, separate solid from liquid, and obtain pretreated graphite after washing and drying. (120g / L) and potassium persulfate (120g / L) concentrated sulfuric acid to oxidize and dehydrate the pretreated graphite, stir at 60°C for 6h, separate solid from liquid, and obtain preoxidized graphite after washing and drying. The mass ratio of sulfuric acid to pretreated graphite is 0.5:0.5; add preoxidized graphite, sodium nitrate, and potassium permanganate in sequence to concentrated sulfuric acid, and then place it in a water bath at 40°C for 8 hours, wherein concentrated sulfuric acid and preoxidized The mass ratio of graphite is 0.5:1, and the graphite of preoxidation: sodium nitrate: the mass ratio of potass...

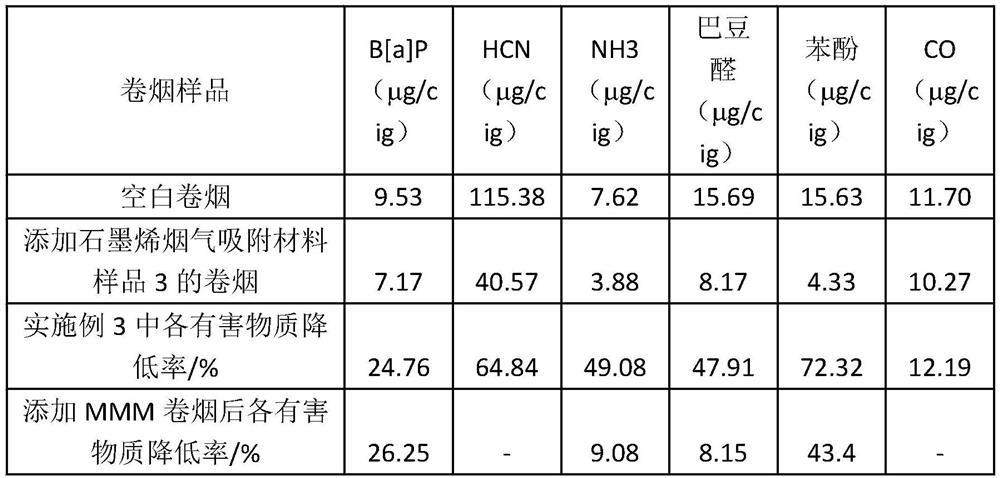

Embodiment 3

[0044] Present embodiment is the preparation of a kind of graphene flue gas adsorption material sample 3, comprises the following steps:

[0045] (1) Add flake graphite into a single-necked flask equipped with hydrochloric acid-hydrofluoric acid mixture (volume ratio 1.5:1) and stir for 5 hours, separate solid from liquid, and obtain pretreated graphite after washing and drying. (150g / L) and potassium persulfate (150g / L) concentrated sulfuric acid to oxidize and dehydrate the pretreated graphite, stir at 50°C for 6h, separate solid from liquid, and obtain preoxidized graphite after washing and drying. The mass ratio of sulfuric acid to pretreated graphite is 1:0.5; add preoxidized graphite, sodium nitrate, and potassium permanganate in sequence to concentrated sulfuric acid, and then place it in a water bath at 50°C for 5 hours, where concentrated sulfuric acid and preoxidized The mass ratio of graphite is 0.5:0.75, and the graphite of preoxidation: sodium nitrate: the mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com