A titanium dioxide porphyrin-based covalent organic framework composite material and its preparation method and application

A technology of covalent organic framework and titanium dioxide, applied in chemical instruments and methods, catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, etc., can solve slow electron transfer, limited application, carrier recombination Efficiency barriers and other issues, to achieve the effect of strong electron feeding ability, improved utilization rate, and high industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

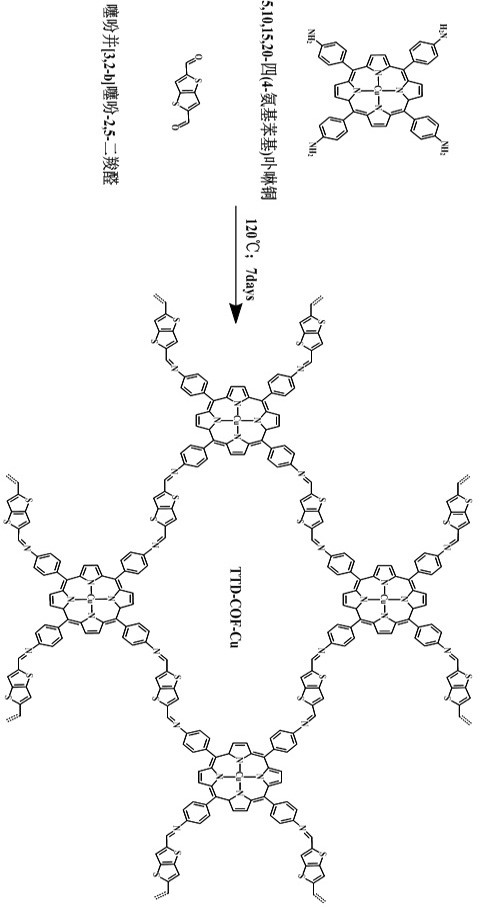

[0026] Copper 5,10,15,20-tetrakis(4-aminophenyl)porphyrin (14.8 mg, 0.02 mmol) and thieno[3,2-b]thiophene-2,5-dicarbaldehyde (8 mg, 0.04 mmol ) into a Pyrex tube (about 5 mL in volume, 20 cm in length, and 1 cm in diameter), add 0.925 mL of benzyl alcohol and 0.077 mL of n-butanol and sonicate for 1 minute to disperse evenly, then add 0.2 mL of 6 M acetic acid . The Pyrex tube was then frozen and thawed in liquid nitrogen, evacuated three times to bring its internal pressure to 0 mbar and flame-tight. Then the Pyrex tube was placed in an oven at 120 °C for 7 days. Wash three times with tetrahydrofuran and acetone, collect the product by suction filtration, and dry the collected purple powder in vacuum at 70° C. overnight.

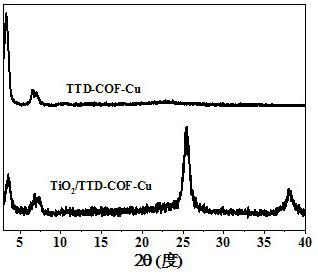

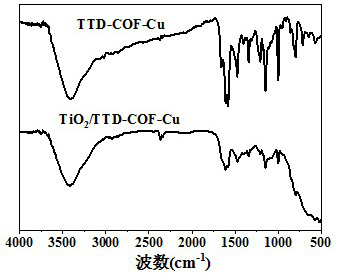

[0027] Weigh 20mg of TTD-COF-Cu, add it into a beaker filled with 20mL of absolute ethanol, continue to slowly add 43μL of titanium tetra-n-butoxide and 0.5mL of water into the beaker successively, while stirring continuously. Then the mixed solution was...

Embodiment 2

[0029] Weigh 10 mg TiO 2 / TTD-COF-Cu, add 500mg sodium ascorbate and 3wt% Pt, add 50mL water, put it into a special quartz glass reactor after ultrasonication for 5 minutes. After the reactor was evacuated, a 300 W xenon lamp was used to simulate visible light (λ ≥ 420 nm) at 303–323 K. During the photocatalytic reaction, the gas composition after the photocatalytic reaction was detected by gas chromatography at intervals of 1 hour, as shown in Figure 6 As shown, pure TiO 2 The yield is 303 (μmol / g) / h, pure TTD-COF-Cu and the material after physically mixing the two in the same proportion have no catalytic activity, but the composite material TiO 2 H of / TTD-COF-Cu 2 The yield can reach 656.5 (μmol / g) / h. Therefore, it can be explained that the composite material in the present invention can effectively improve the photocatalytic activity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com