Fermentation conversion method and application of madecassoside

A technology of madecassoside and asiaticoside, which is applied to the application of madecassoside fermentation liquid and the field of centella asiaticoside fermentation, and can solve the problems of high cost, complicated operation, and large amount of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a fermentative transformation method of madecassoside. The preparation method comprises: using Centella asiatica or the crude extract of Centella asiatica or asiaticoside or a combination thereof as a raw material, by Microbial fermentation to prepare Centella asiatica fermented liquid rich in madecassoside;

[0045] Alternatively, the Centella asiaticoside fermented liquid rich in madecassoside is prepared by using the centella asiatica fermented liquid or the crude extract of centella asiatica or asiaticoside as a raw material through secondary fermentation of microorganisms;

[0046] post-processing the fermentation broth rich in madecassoside to obtain pure madecassoside;

[0047] Wherein, the microorganisms include thermophilic bacteria or a multi-bacteria composition composed of thermophilic bacteria and non-thermophilic bacteria.

[0048] Preferably, the thermophilic bacteria include one of Thermus thermophilus, Streptococcus thermophilus,...

Embodiment 1

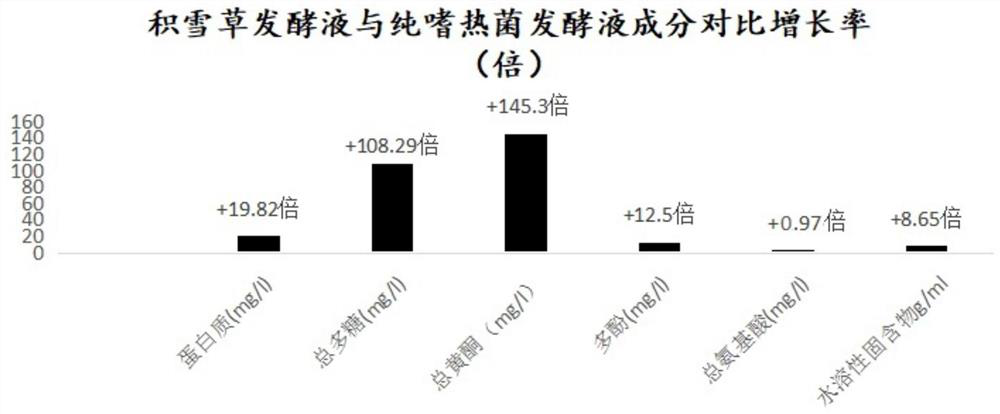

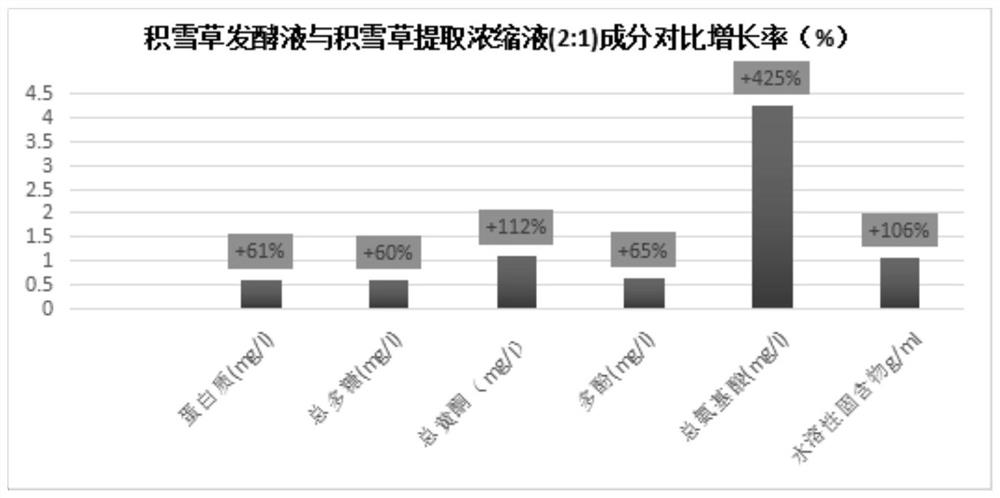

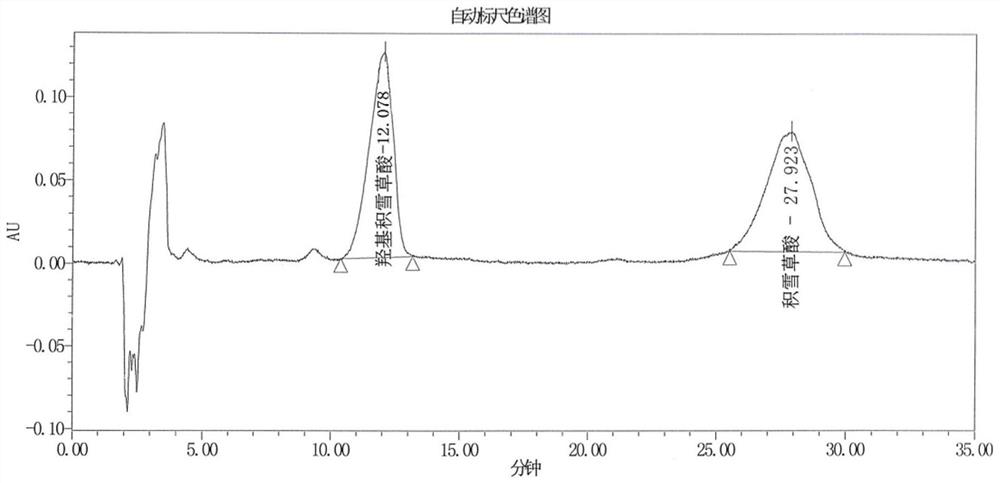

[0057] Centella asiatica was added to the medium of Thermus thermophiles, and cultured and fermented according to the fermentation process of Thermus thermophiles (60°C, 48h). Two concentrations of Centella asiatica were selected: 5g / L, 50g / L And with the same concentration of Centella asiatica water extract (60°C, 48h), and the concentrated solution of the same concentration of Centella asiatica water extract (concentrated into a medicinal material: concentrated solution ratio of 2:1, that is, 2g of medicinal materials to obtain a concentrated solution 1g) and the pure Thermus thermophilus fermented liquid without adding Centella asiatica were analyzed and compared, the results are shown in Table 1 and figure 1 , figure 2 : (1) Comparative data of various ingredients

[0058] Table 1 Composition comparison of Centella asiatica fermented liquid and pure thermophilic Thermus fermented liquid, Centella asiatica water extract, same concentration of Centella asiatica water extra...

Embodiment 2

[0076] Add asiaticoside (addition amount 50g / L) to the culture medium of the dual-bacteria composition of thermophilic bacteria and lactic acid bacteria, first ferment the lactic acid bacteria at (28°C, 18h) according to the fermentation process, and then transfer to Fermentation of Thermus thermica (78°C, 8h) for cultivation and fermentation, adding the fermented liquid to D330 resin to decolorize at a flow rate of 2BV / H, after centrifugal filtration, to obtain Centella asiatica fermented liquid rich in madecassoside, and then The pure product of madecassoside is obtained through post-treatment processes such as conventional purification and crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com