Preparation method of mung bean sprout yoghourt

A technology of mung bean sprouts and yogurt, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of inefficient enrichment, poor strain stability, and complicated steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

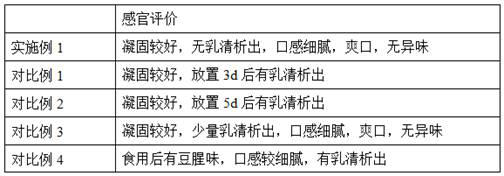

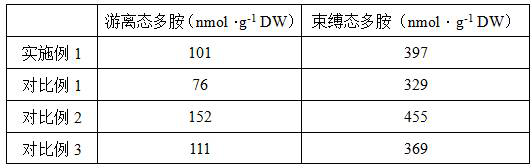

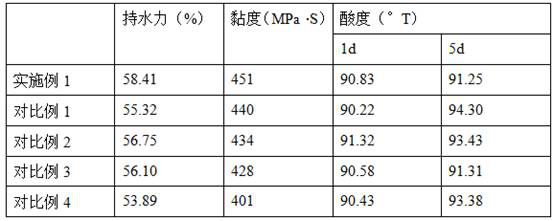

Examples

Embodiment 1

[0031] The selected mung bean seeds were soaked in 1% sodium hypochlorite aqueous solution for 20 minutes to disinfect them, and then placed in 5 times the volume (v / w) of drinking water, soaked at 30 °C for 5 hours, and the soaked The mung bean seeds were placed in a germination machine and germinated in the dark at 30 °C for 48 h, sprayed with spray liquid for 2 min every 1 h, the flow rate of the spray liquid was 200 mL / min, and the spray liquid was 6 mM CaCl 2 Mixed aqueous solution with 180 μM putrescine and 1g / L mussel mucin; peeled and washed mung bean sprouts, heated at 95 ℃ for 10 min, then cooled rapidly, drained the surface water and mixed with drinking water at a ratio of 1:3 (w / v) Mix and beat in proportion, filter through four layers of gauze to obtain mung bean sprout pulp; in the above mung bean sprout pulp, add fresh milk at a mass ratio of 1: 1.5, add 8% white sugar, mix well, and place in a water bath at 60 °C Preheat in the pot, stir to dissolve the white...

Embodiment 2

[0033] Mung bean grain selection, disinfection, soaking methods are the same as in Example 1. The soaked mung bean seeds were placed in a germination machine and germinated at 30 °C in the dark for 60 h, and sprayed with spray liquid for 2 min every 1 h, the flow rate of the spray liquid was 250 mL / min, and sprayed 6 mM CaCl 2Mixed aqueous solution with 180 μM putrescine and 1g / L mussel mucin; peeled and washed mung bean sprouts, heated at 95 ℃ for 10 min, then cooled rapidly, drained the surface water and mixed with drinking water at a ratio of 1:2 (w / v) Mix and beat in proportion, filter through four layers of gauze to obtain mung bean sprout pulp; in the above mung bean sprout pulp, add fresh milk at a mass ratio of 1: 2.3, add 6% white sugar, mix well, and place in a water bath at 60 °C Preheat in the pot, stir and dissolve the white granulated sugar, homogenize at 25 MPa for 5 minutes, then heat to 95°C, keep warm for 15 minutes, and cool to 42°C; Add 5% mixed bacteria...

Embodiment 3

[0035] Mung bean grain selection, disinfection, soaking methods are the same as in Example 1. The soaked mung bean seeds were placed in a germination machine, germinated at 30 °C in the dark for 48 h, sprayed with spray liquid for 2 min every 1 h, the flow rate of the spray liquid was 200 mL / min, and the spray liquid 6 mM CaCl 2 Mixed aqueous solution with 180 μM putrescine and 1g / L mussel mucin; peeled and washed mung bean sprouts, heated at 95 ℃ for 10 min, then cooled rapidly, drained the surface water and mixed with drinking water at a ratio of 1:3 (w / v) Mix and beat in proportion, filter through four layers of gauze to obtain mung bean sprout pulp; in the above mung bean sprout pulp, add fresh milk at a mass ratio of 1: 1, add 7% white sugar, mix well, and place in a water bath at 60 °C Preheat in the pot, stir and dissolve the white granulated sugar, homogenize at 25 MPa for 5 minutes, then heat to 95°C, keep warm for 15 minutes, and cool to 42°C; Add 5% mixed bacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com