High-efficiency non-noble metal water electrolysis catalytic material as well as preparation method and application thereof

A catalytic material, non-precious metal technology, applied in the field of high-efficiency non-precious metal electrolysis water catalytic materials, to achieve the effect of low production cost, stable structure, and favorable formation and exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

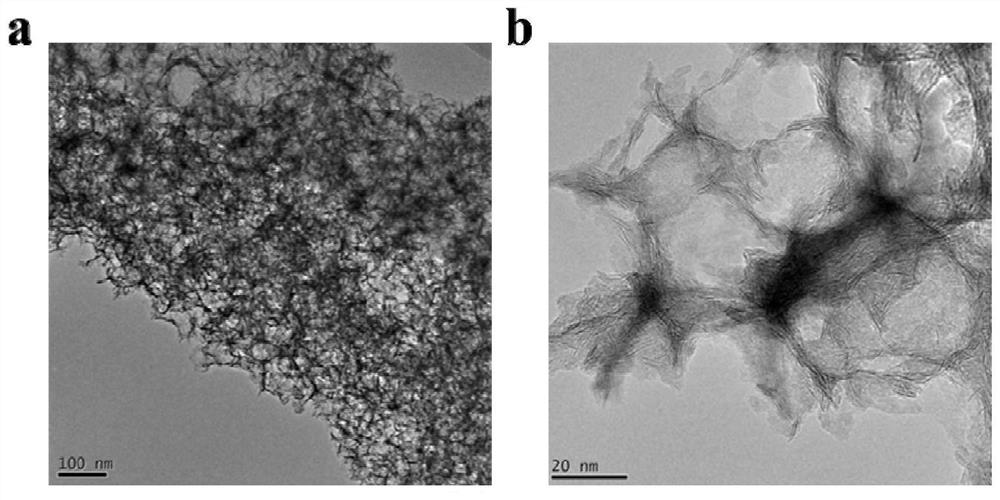

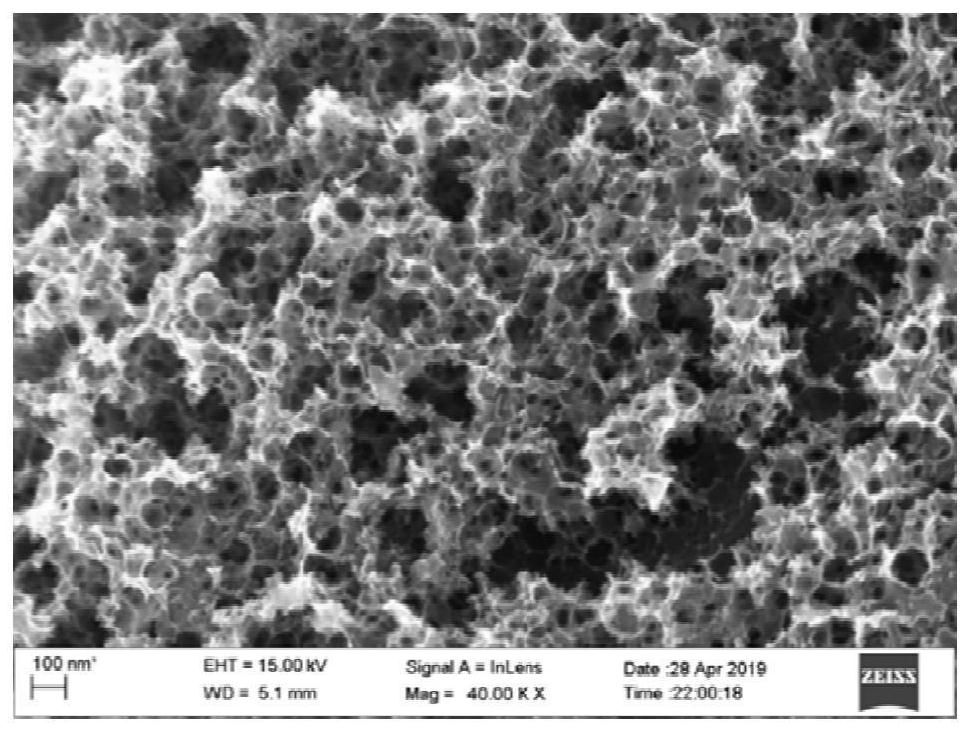

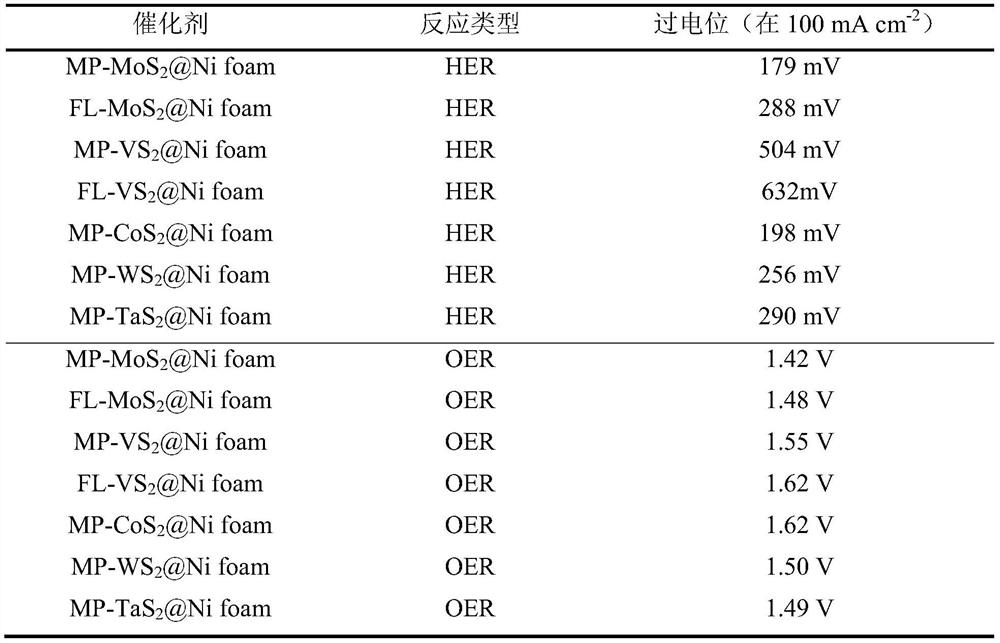

Image

Examples

Embodiment 1

[0041] 1. Cut a certain size of nickel foam (1*1cm, 300PPI, 3mm), put it in ultrapure water, acetone, hydrochloric acid (1M) and ultrapure water for ultrasonication, each ultrasonic time is 20min, and then place it in a vacuum oven Dry for 12 hours;

[0042]2. Dissolve 1.7mg of ammonium molybdate and 7mg of thiourea in 2mL of water, then add 50mg of silicon dioxide (100nm, 30wt.%) and 0.5mL of ethanol, stir and mix well, and then sonicate for 60min;

[0043] 3. Take the mixed solution in step (2) and drop-coat it directly on the nickel foam, so that the precursor is evenly loaded on the nickel foam. After baking for 3 hours under a 100W infrared lamp, place it in a vacuum dryer and dry it for 10 hours. The drying temperature is 60°C;

[0044] 4. Transfer the product obtained in step (3) to a tube furnace, and in an argon atmosphere, program the temperature to 400°C at a heating rate of 10°C / min, the mixed gas flow rate is 80mL / min, and then keep it for 240min;

[0045] 5. Mi...

Embodiment 2

[0048] 1. Cut a certain size of nickel foam (1*1cm, 300PPI, 3mm), put it in ultrapure water, acetone, hydrochloric acid (1M) and ultrapure water for ultrasonication, each ultrasonic time is 20min, and then place it in a vacuum oven Dry for 12 hours;

[0049] 2. Dissolve 13.3mg of sodium tungstate and 7mg of thiourea in 2mL of water, then add 50mg of silicon dioxide (100nm, 30wt.%) and 0.5mL of ethanol, stir and mix well, and then sonicate for 60min;

[0050] 3. Take the mixed solution in step (2) and drop-coat it directly on the nickel foam, so that the precursor is evenly loaded on the nickel foam. After baking for 3 hours under a 100W infrared lamp, place it in a vacuum dryer and dry it for 10 hours. The drying temperature is 60°C;

[0051] 4. Transfer the product obtained in step (3) to a tube furnace, and in an argon atmosphere, program the temperature to 400°C at a heating rate of 10°C / min, the mixed gas flow rate is 80mL / min, and then keep it for 240min;

[0052] 5. Mi...

Embodiment 3

[0055] 1. Cut a certain size of nickel foam (1*1cm, 300PPI, 3mm), put it in ultrapure water, acetone, hydrochloric acid (1M) and ultrapure water for ultrasonication, each ultrasonic time is 20min, and then place it in a vacuum oven Dry for 12 hours;

[0056] 2. Dissolve 23.7mg of cobalt nitrate and 7mg of thiourea in 2mL of water, then add 50mg of silicon dioxide (100nm, 30wt.%) and 1mL of ethanol, stir and mix well, and then sonicate for 60min;

[0057] 3. Take the mixed solution in step (2) and drop-coat it directly on the nickel foam, so that the precursor is evenly loaded on the nickel foam. After baking for 3 hours under a 100W infrared lamp, dry for 10 hours at a drying temperature of 60 ° C;

[0058] 4. Transfer the product obtained in step (3) to a tube furnace, and in an argon atmosphere, program the temperature up to 400°C at a heating rate of 10°C / min, with a mixed gas flow rate of 80ml / min, and then keep it for 240min;

[0059] 5. Mix 25mL of hydrofluoric acid, 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com