Transparent electromagnetic shielding film

An electromagnetic shielding film, transparent technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of high processing costs, polluting the environment, and long time consumption, and achieve excellent optical performance, high light transmittance, and no pinholes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

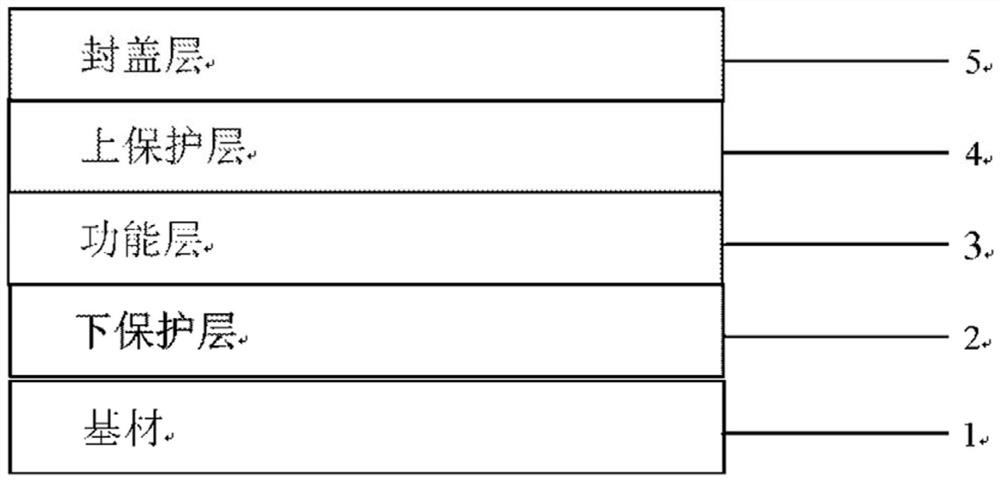

Image

Examples

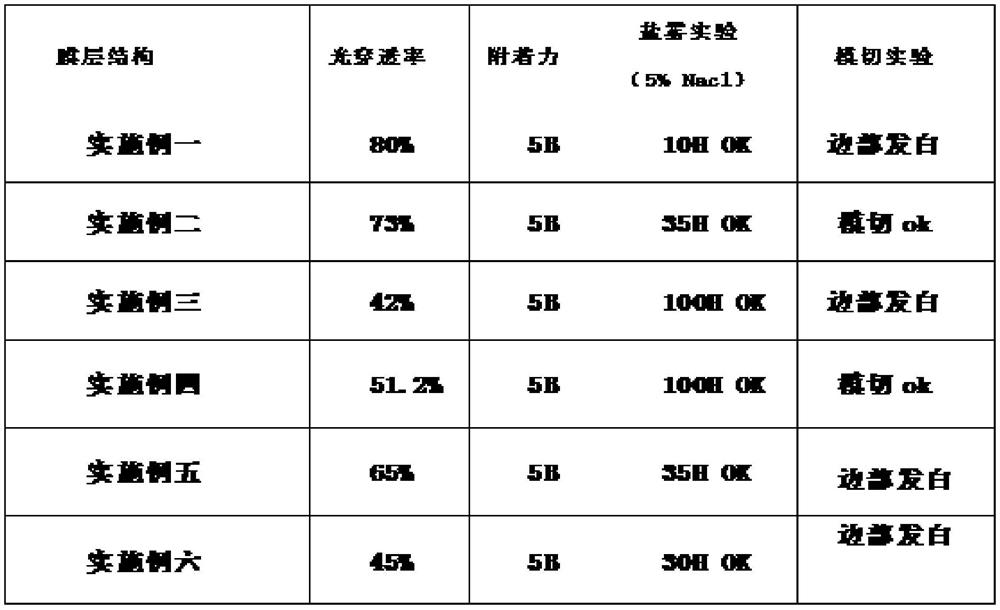

Embodiment 1

[0023] In Example 1, the lower protective layer 2 is made of silicon dioxide, the metal functional layer 3 is made of silver alloy, the upper protective layer 4 is made of silicon dioxide, and the capping layer 5 is made of titanium oxide. After testing in this embodiment, the light transmittance is as high as 80%, adhesion 5B, salt spray test (5% Nacl) can only resist corrosion for 10H, die cutting test found that the edge is whitish.

Embodiment 2

[0024] Example 2, the lower protective layer 2 is made of silicon dioxide, the metal functional layer 3 is made of silver alloy, the upper protective layer 4 is made of aluminum oxide-doped zinc oxide, wherein the content of zinc oxide is 50%-99%, and the sealing layer 5 is made of Niobium pentoxide, this embodiment is tested, the light transmittance is as high as 73%, the adhesion is 5B, the salt spray test (5% Nacl) can resist corrosion for 35H, and the die-cutting test is up to standard.

Embodiment 3

[0025] Example 3, the lower protective layer 2 is aluminum oxide-doped zinc oxide, the metal functional layer 3 is silver alloy, the upper protective layer 4 is nickel-chromium alloy, and the capping layer 5 is silicon dioxide. After testing in this embodiment, the oxidation The zinc content is 50%-99%, the light transmittance is as high as 42%, the adhesion is 5B, the salt spray test (5% Nacl) can resist corrosion for 100H, and the die-cutting test shows that the edge is whitish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com