Preparation method of blue pearlescent pigment based on ultramarine pigment

A technology of pearlescent pigments and cyan pigments, applied in the field of materials, can solve problems such as irregular shapes and inability to ensure the compactness of the coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

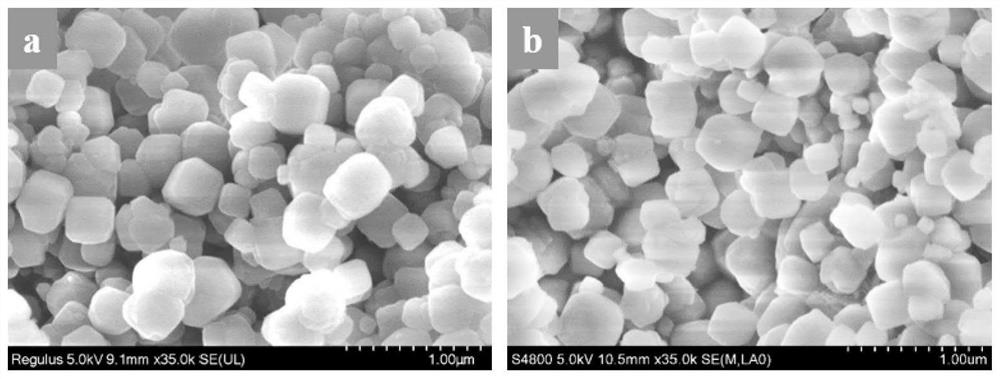

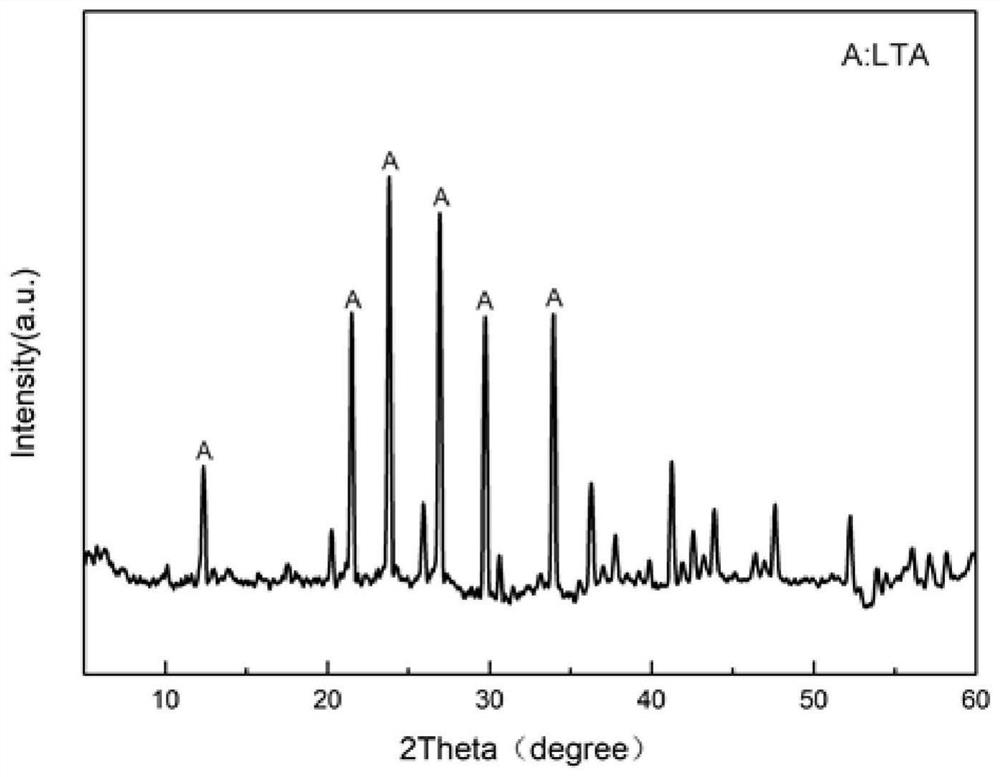

[0031] Example 1 Preparation of nano ultramarine particles.

[0032] Take 1.23g of sodium aluminate, 15g of water, 2g of sodium hydroxide, and 2.25g of colloidal silica and add in order to mix. The synthetic solution is stirred and dynamically aged for 20 hours at room temperature, then transferred to a reaction kettle and heated at 80°C for 6 hours, and the product is washed until the pH2 S 3 After immersing in aqueous solution (30%) for 22 hours, dry at 120°C; put the dried solid in a crucible, place it in an atmosphere furnace, pass in nitrogen for 30 minutes, heat up to 600°C at a rate of 5°C / min and calcinate for 1 hour , after cooling to room temperature, air was introduced for 30 min, the temperature was raised to 350 °C at a rate of 10 °C / min, and air was calcined for 2 h, then cooled to room temperature to obtain a blue pigment cake. The pigment cake is washed with water for several times, filtered, dried and ground to obtain a nanoscale blue sample with a uniform par...

Embodiment 2

[0036] A kind of blue pearlescent pigment based on ultramarine blue pigment, its specific preparation process is as follows:

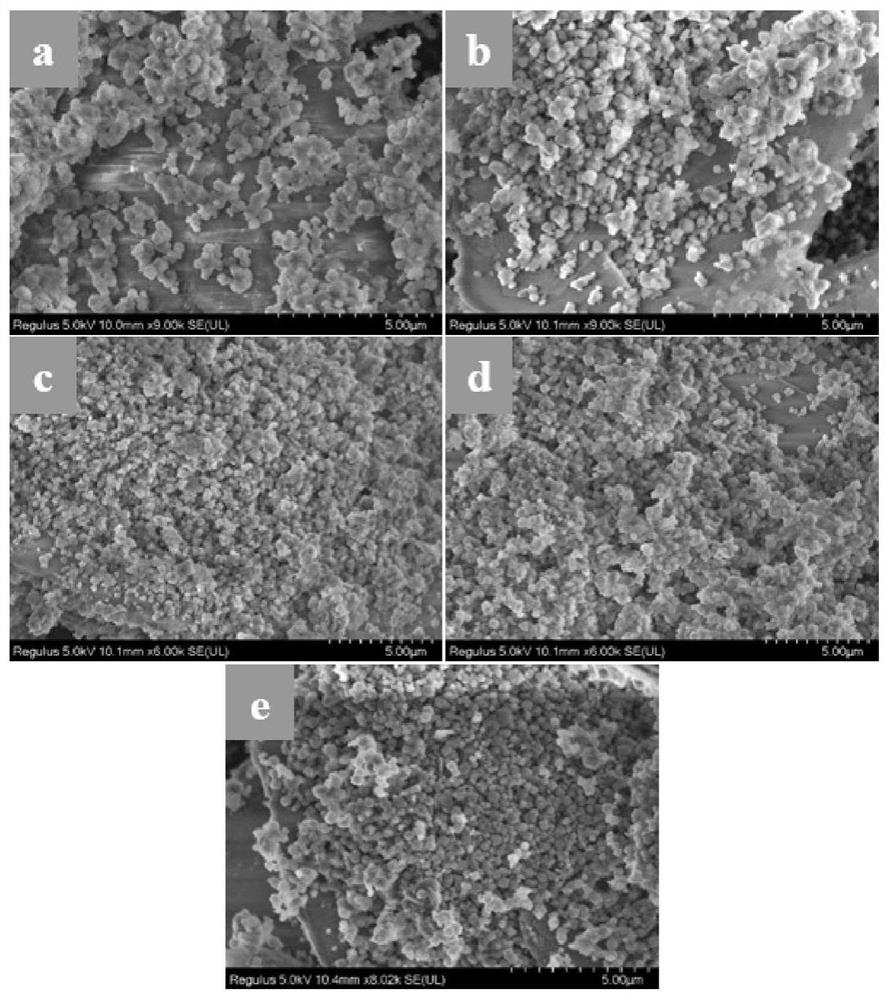

[0037] Take 1g nano ultramarine particles, 25g ethanol, 4.5g ammonia water and mixed zirconia beads with different particle sizes in a 100mL ball mill jar, add 1g silicone-oxygen coupling agent KH-560 to it at the same time, seal the jar and place it in a planetary ball mill During the reaction at 400rpm rotating speed for 4h, the ultramarine granules modified by KH-560, 0.3g mica powder and 30g DMF were obtained after finishing with ethanol centrifugal washing, drying and grinding to In a 100mL three-necked flask, the reaction was stirred at 130°C for 4h. After the reaction is finished, a cake-like product is obtained, and then a powder mica-ultramarine compound is obtained after further conventional ultrasonication, washing, drying and grinding. Its SEM-EDX mapping such as Image 6 as shown, Image 6 On the middle mica sheet, the element distribut...

Embodiment 3

[0047] A kind of blue pearlescent pigment based on ultramarine blue pigment, its specific preparation process is as follows:

[0048] Take 1g nano ultramarine particles, 25g ethanol, 4.5g ammonia water and mixed zirconia beads with different particle sizes in a 100mL ball mill jar, add 1g silicone-oxygen coupling agent KH-560 to it at the same time, seal the jar and place it in a planetary ball mill During the reaction at 400rpm rotating speed for 4h, after the end, the ultramarine granules modified by KH-560 were obtained by centrifugal washing with ethanol, drying and grinding; the ultramarine granules modified by 0.9g KH-560, 0.3g mica powder and 30g DMF were placed in In a 100mL three-necked flask, the reaction was stirred at 130°C for 4h. After the reaction, the sample was processed by ultrasonication, washing, drying, grinding, etc. to obtain the mica-ultramarine complex. Figure 7 Appears near 600nm and belongs to S 3 - The peak in the 400-500nm wavelength range has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com