Flame-retardant composite diaphragm, preparation method thereof and lithium ion battery

A flame-retardant composite and diaphragm technology, applied in the field of lithium-ion batteries, can solve the problems of restricting rapid development, affecting the electrochemical performance of lithium-ion batteries, breaking through, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

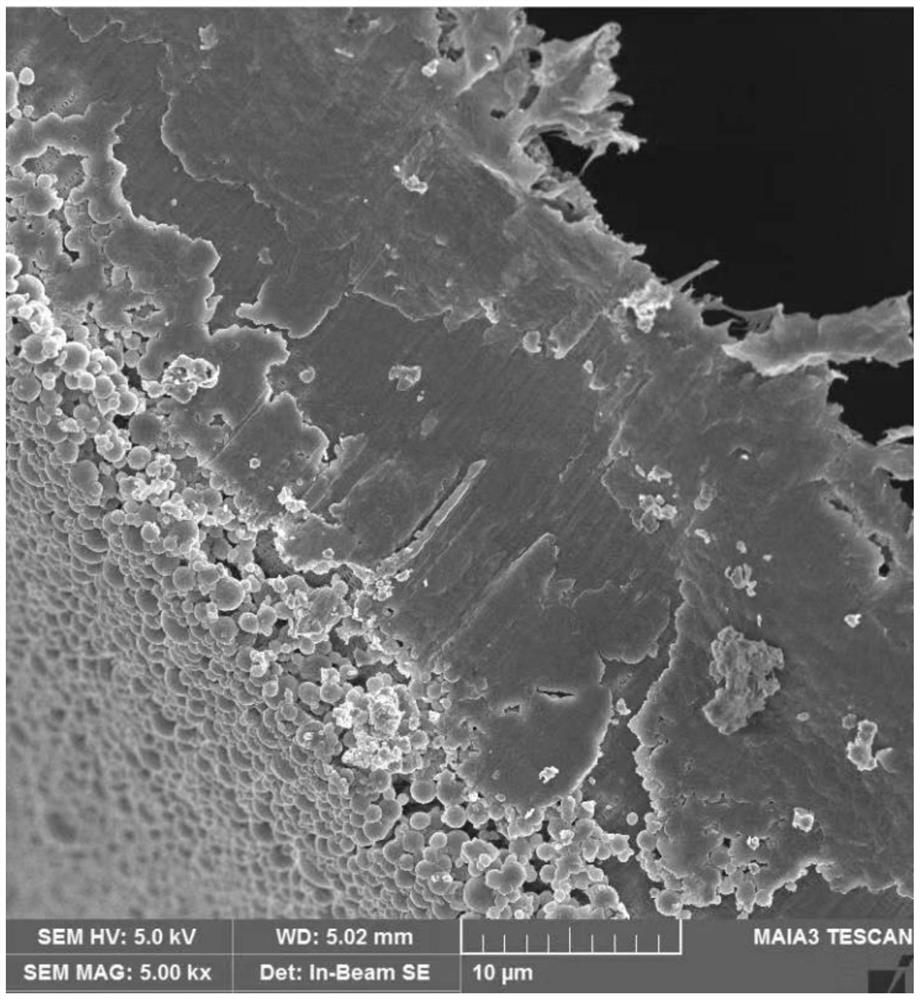

Image

Examples

preparation example Construction

[0084] The present invention also provides a preparation method of flame retardant microcapsules, comprising the following steps:

[0085] 1) Under the condition of protective gas, after dispersing the emulsifier and water, an emulsion is obtained;

[0086] 2) Under the condition of protective gas, add the monomer and cross-linking agent of the inner wall material to the emulsion obtained in the above steps for initial emulsification, then add the core material and initiator for re-emulsification, and finally Carry out heating reaction, obtain monolayer microcapsule;

[0087] 3) After mixing the single-layer microcapsules obtained in the above steps and the molten liquid of the outer capsule wall material, spray drying to obtain flame-retardant microcapsules.

[0088] The parameters, selections, and corresponding optimization principles of raw materials and products in the above-mentioned preparation method in the present invention can correspond to the parameters, selections...

Embodiment 1

[0154] (1) Preparation of double-layer flame retardant microcapsules:

[0155] A. Add 30ml methyl methacrylate to the emulsion containing 2.5g Triton X-100, emulsify and disperse evenly under nitrogen atmosphere, add ethylene glycol dimethacrylate and stir for 30min, add 30ml tribromomethyl phosphoric acid The ester and 0.2 g of azobisisoheptanonitrile were reacted at 45° C. for 5 h, and sodium chloride was added to terminate the reaction, washed and dried to obtain polymethyl methacrylate-coated microcapsules of tribromomethyl phosphate.

[0156] B. Add the microcapsules prepared in A to polyethylene melt, and spray-dry at 50° C. to obtain polyethylene-coated double-layer flame-retardant microcapsules.

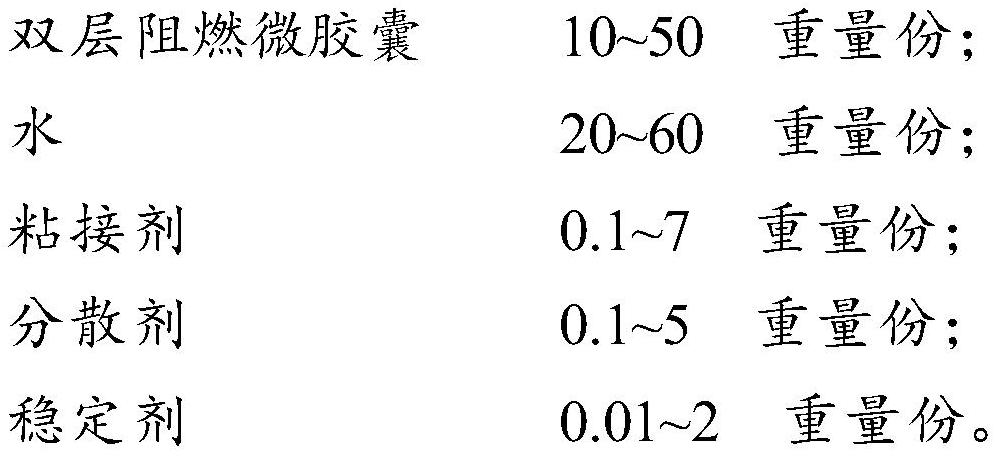

[0157] (2) Preparation of flame retardant diaphragm

[0158] A. Mix double-layer flame-retardant microcapsules with a mass ratio of 25:6:0.5:3.5:65, polyacrylic acid, ethylene glycol, fatty alcohol polyoxyethylene ether, and deionized water, and stir at high speed to obtain ...

Embodiment 2

[0177] (1) The preparation process of the double-layer flame-retardant microcapsules is the same as in Example 1.

[0178] (2) Preparation of flame retardant diaphragm:

[0179] A. Mix double-layer flame-retardant microcapsules with a mass ratio of 25:6:0.5:3.5:65, polyacrylic acid, ethylene glycol, fatty alcohol polyoxyethylene ether, and deionized water, and stir at high speed to obtain a double-layer flame-retardant microcapsule. capsule slurry;

[0180] B. Apply the double-layer flame-retardant microcapsule slurry to the side of the PP diaphragm (thickness 9 μm, porosity 45%) by spray coating, and the median thickness of the coating is 6 μm to obtain a flame-retardant diaphragm;

[0181] (3) The preparation process of the lithium-ion battery is the same as in Example 1.

[0182] The lithium-ion battery prepared in Example 2 of the present invention was tested for cycle performance, gas permeability and acupuncture performance.

[0183] Cycle performance test: the number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com