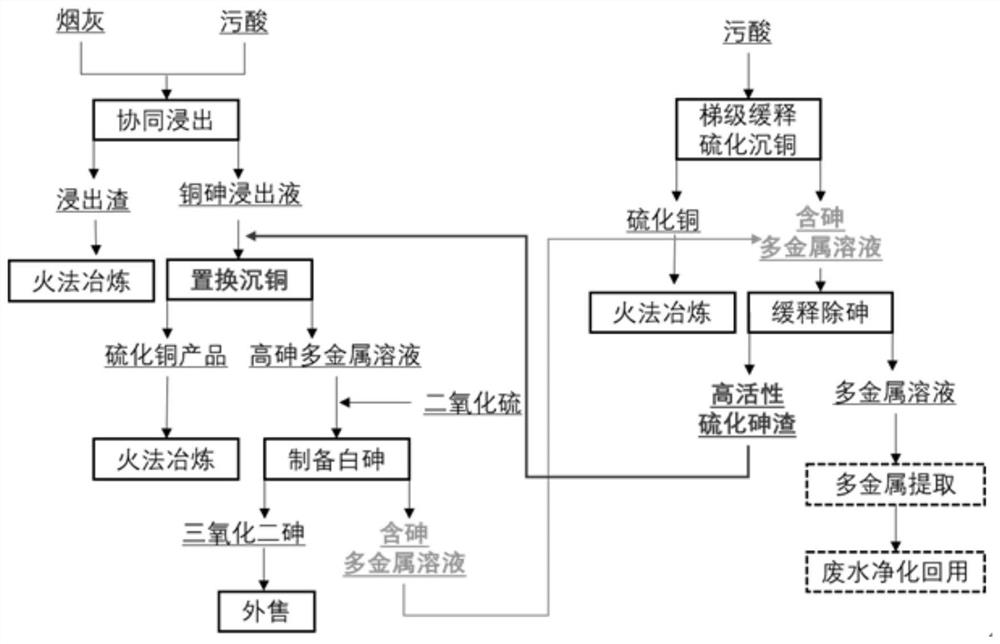

Method for recycling multiple metals through resource cooperative treatment of copper smelting white smoke dust and waste acid

A white smoke, polymetallic technology, applied in chemical instruments and methods, inorganic chemistry, arsenic compounds, etc., can solve the problems of increased processing burden and poor separation effect, and achieve the effects of low cost, fast settling speed and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Soot and polluted acid produced during the smelting process of a copper concentrate oxygen-enriched bottom blowing smelting pool in a domestic enterprise, the main components of copper soot are (%): Pb 24.9, Cu 14.2, As 5.8, Bi 2.5, Zn 2.5, Fe 1.4. The main components of dirty acid are (g / L): As 2.1, Cu 0.5, Bi 0.3, H 2 SO 4 205. Dilute the polluted acid by one time and cooperate with copper soot for leaching. The leaching conditions are: solid-to-liquid ratio 1:5, leaching temperature 25°C, leaching time 1h. The leaching rate of copper and arsenic in the leaching solution is more than 99%, and the leaching rate of arsenic is more than 85%. The lead and bismuth are basically all entered into the slag, and the grades of lead and bismuth slag are 54.2% and 5.2% respectively.

[0045] The slow-release vulcanizing agent used is prepared by the following method: MnSO 4 with Na 2 S 2 o 3 According to molar ratio 1.2:1, react 30min at room temperature, the tensio-activ...

Embodiment 2

[0048] The soot and lead smelting sewage acid produced by a domestic enterprise copper concentrate, the main components of copper soot, in mass percentage (%): Pb 36.6, Cu 8.2, As 14.3, Bi 1.6, Zn 3.5, Fe 0.7. The main components of dirty acid are (g / L): As3, Cu 2, Bi 0.5, H 2 SO 4 70. Synergistic oxidative leaching of polluted acid and copper soot, the leaching conditions are: 30% hydrogen peroxide 20mL / L as oxidant, solid-liquid ratio 1:3, leaching temperature 65°C, leaching time 1h. The leaching rate of copper and arsenic in the leaching solution is more than 99%, and the leaching rate of arsenic is more than 96%. The lead and bismuth are basically all entered into the slag, and the grades of lead and bismuth slag are 61.8% and 3.4% respectively.

[0049] The slow-release vulcanizing agent used is to calcinate excess iron powder and sulfur at a temperature of 350°C under a protective atmosphere. The molar ratio of iron powder to sulfur is 1.2:1; the protective atmosphere...

Embodiment 3

[0052] The soot and lead smelting sewage acid produced by a domestic enterprise copper concentrate, the main components of copper soot, in mass percentage (%): Pb 36.6, Cu 8.2, As 14.3, Bi 1.6, Zn 3.5, Fe 0.7. The main components of dirty acid are (g / L): As3, Cu 2, Bi 0.5, H 2 SO 4 70. Synergistic oxidative leaching of polluted acid and copper soot, the leaching conditions are: 30% hydrogen peroxide 20mL / L as oxidant, solid-liquid ratio 1:3, leaching temperature 65°C, leaching time 1h. The leaching rate of copper and arsenic in the leaching solution is more than 99%, and the leaching rate of arsenic is more than 96%. The lead and bismuth are basically all entered into the slag, and the grades of lead and bismuth slag are 61.8% and 3.4% respectively.

[0053] The slow-release vulcanizing agent used is to calcinate natural pyrite with a purity of 95% at a temperature of 550° C. under a protective atmosphere, and the protective atmosphere is nitrogen. The atmosphere used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com