Mobile phone surface antibacterial coating and spraying process thereof

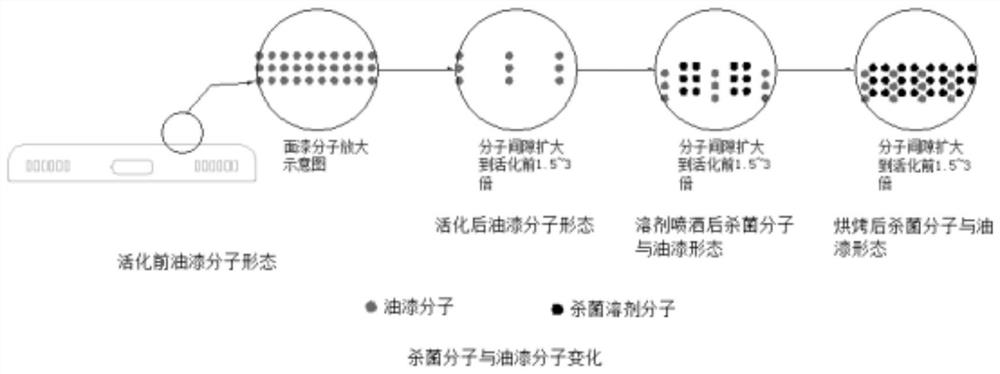

A surface antibacterial and antibacterial coating technology, which is applied to the device, coating, and pretreatment surface of the surface coating liquid, can solve the problems of lack of antibacterial performance, antibacterial performance measurement, etc., to achieve sterilization and inhibition of bacterial reproduction, Uniform, easy-to-remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] An antibacterial coating on the surface of a mobile phone, the antibacterial coating comprising the following raw materials in parts by weight: 0.7 parts of γ-aminopropyltriethoxysilane, 10 parts of modified nano silicon dioxide, 70 parts of caprolactam, oxalic acid 17 parts, 6 parts of tetrabutyl titanate, 0.4 parts of didecyl dimethyl ammonium bromide, 0.4 parts of dibasic lead phosphite, 80 parts of polyisoprene, 8 parts of polyamide wax micropowder;

[0058] Also includes antibacterial emulsion, described antibacterial emulsion comprises the raw material of following parts by weight: 1.4 parts of calcium ricinoleate, 0.2 part of hydrolyzed polymaleic anhydride, 1 part of allyl polyethylene glycol, 0.7 part of polybenzimidazole, acrylic acid Calcium acid 0.1 part, isothiazolinone 0.2 part, coconut acid diethanolamide 1 part and deionized water 80 parts.

[0059] The preparation method of antibacterial emulsion comprises the following steps:

[0060] (a) Take 30% of ...

Embodiment 2

[0069] An antibacterial coating on the surface of a mobile phone, the antibacterial coating comprising the following raw materials in parts by weight: 0.8 parts of γ-aminopropyltriethoxysilane, 12 parts of modified nano silicon dioxide, 80 parts of caprolactam, oxalic acid 18 parts, 8 parts of tetrabutyl titanate, 0.6 parts of didecyl dimethyl ammonium bromide, 0.6 parts of dibasic lead phosphite, 85 parts of polyisoprene, 15 parts of polyamide wax micropowder;

[0070] Also includes antibacterial emulsion, described antibacterial emulsion comprises the following raw materials in parts by weight: 1.7 parts of calcium ricinoleate, 0.25 parts of hydrolyzed polymaleic anhydride, 2 parts of allyl polyethylene glycol, 0.8 part of polybenzimidazole, acrylic acid Calcium acid 0.2 parts, isothiazolinone 0.3 parts, coconut acid diethanolamide 2 parts and deionized water 90 parts.

[0071] The preparation method of antibacterial emulsion comprises the following steps:

[0072] (a) Take...

Embodiment 3

[0080] An antibacterial coating on the surface of a mobile phone, the antibacterial coating comprising the following raw materials in parts by weight: 1 part of γ-aminopropyltriethoxysilane, 13 parts of modified nano silicon dioxide, 85 parts of caprolactam, oxalic acid 20 parts, 10 parts of tetrabutyl titanate, 0.7 parts of didecyldimethylammonium bromide, 0.7 parts of dibasic lead phosphite, 90 parts of polyisoprene, 20 parts of polyamide wax micropowder;

[0081] Also includes antibacterial emulsion, said antibacterial emulsion includes the following raw materials in parts by weight: 2 parts of calcium ricinoleate, 0.3 part of hydrolyzed polymaleic anhydride, 2 parts of allyl polyethylene glycol, 1 part of polybenzimidazole, acrylic acid 0.3 parts of calcium carbonate, 0.4 parts of isothiazolinone, 2 parts of coconut acid diethanolamide and 100 parts of deionized water.

[0082] The preparation method of antibacterial emulsion comprises the following steps:

[0083] (a) Ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com