Sulfonic acid type solvent-free waterborne polyurethane resin and preparation method thereof

A water-based polyurethane, solvent-free technology, applied in the field of polyurethane, can solve the problems of increasing the cost of solvent recovery, limiting the scope of application, unfavorable environment and human health, etc., and achieves the effects of convenient operation and processing, no environmental pollution, and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of sulfonic acid type solvent-free waterborne polyurethane is as follows:

[0052] Step 1: Drying of polyether polyol

[0053] Weigh 100-200g of polyether polyol, 1-2g of antioxidant, 1-2g of light stabilizer in a four-necked flask equipped with a stirrer, thermometer, constant pressure funnel and vacuum pump, turn on the stirrer, vacuum pump, and pass through the automatic The temperature control system heats the material in the reactor to 100-120°C, adjusts the pressure to ≤-0.08MPa, vacuum distills for 1-2 hours, dehydrates the raw materials, and uses a trace moisture meter to measure the water content below 0.05%.

[0054] Step 2: Preparation of solvent-free waterborne polyurethane prepolymer

[0055] Lower the temperature of the polyol obtained in step (1) to below 80°C, then add 40 to 70 g of diisocyanate to the polyol from a constant pressure funnel, stir evenly, gradually raise the temperature to 80°C to 100°C, and react at a constant tem...

Embodiment 1

[0061] Step 1: Drying of polyether polyol

[0062] First, add 180g polytetrahydrofuran ether glycol (PTMG2000) and 1.44g antioxidant 1010, 1.68g light stabilizer 866 to a 500ml four-necked flask with electric stirring, thermometer, constant pressure funnel and vacuum pump, then turn on the electric stirring for stirring , Turn on the oil bath to heat up, turn on the positive air pump to vacuumize the four-necked flask, start timing when the thermometer on the four-necked flask reaches 110°C and the vacuum pressure is ≤-0.08MPa, keep the temperature at 100°C-120°C, Vacuum dehydration for 1.5h under the condition of pressure ≤ -0.08MPa.

[0063] Step 2: Preparation of solvent-free waterborne polyurethane prepolymer

[0064] When the water content in the polyol is less than 0.05%, turn off the vacuum pump and reduce the temperature of the oil bath. When the temperature of the thermometer drops to 80°C, slowly add 53.02g of isophorone diisocyanate (IPDI) through a constant pressu...

Embodiment 2

[0070] Step 1: Drying of polyether polyol

[0071] Add 146.20g polypropylene glycol (PPG2000) and 25.8g polycarbonate diol (UH-200), 3.56g polyethylene glycol monomethyl ether (N120) and 1.43g antioxidant 1010, 1.66g light stabilizer 866 to 500ml A four-necked flask with an electric stirrer, a thermometer, a constant pressure funnel and a vacuum pump, then turn on the electric stirrer to stir, turn on the oil bath to heat up, turn on the positive vacuum pump to vacuum the inside of the four-necked flask, when the thermometer on the four-necked flask When the temperature reaches 110°C and the vacuum pressure is ≤-0.08MPa, start timing, and keep the temperature between 100°C and 120°C and the pressure is ≤-0.08MPa for vacuum dehydration for 1 hour.

[0072] Step 2: Preparation of solvent-free waterborne polyurethane prepolymer

[0073] When the water content in the polyol is less than 0.05%, turn off the vacuum pump and reduce the temperature of the oil bath. When the temperatu...

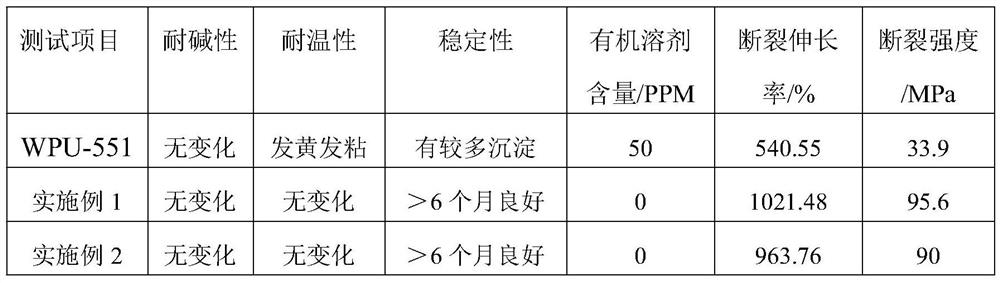

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com