Fluorine-silicon modified multifunctional linseed oil-based alkyd resin UV curing coating and preparation and application thereof

A technology of fluorosilicon modification and alkyd resin, which is applied in the direction of polyester coatings and coatings, can solve the problems of low coating hardness, cumbersome synthesis process, and long curing time, and achieve high reactivity, wide sources, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

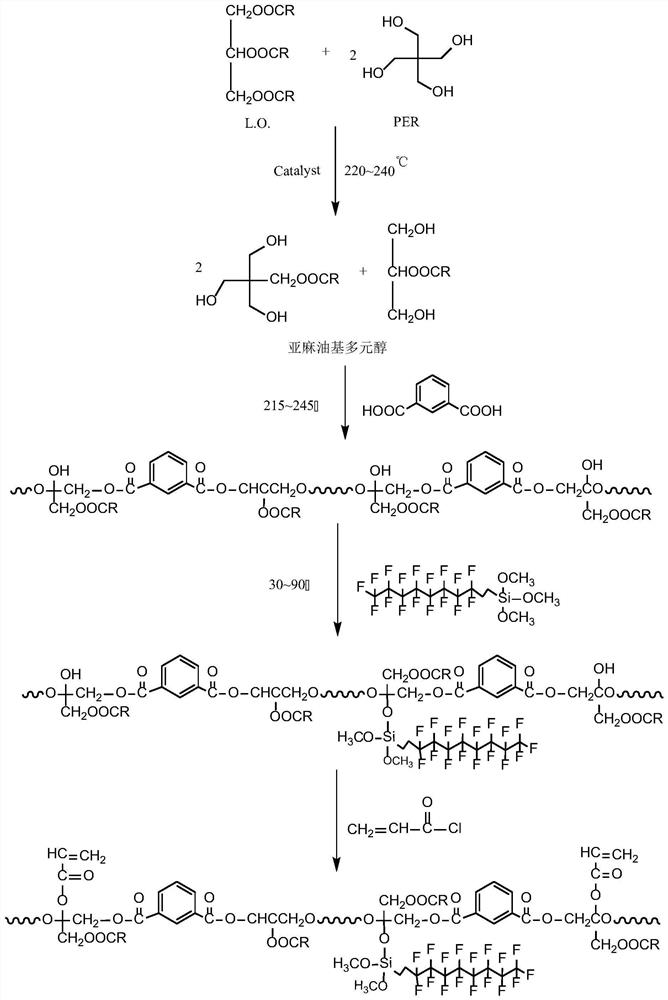

[0035] 1. A preparation method of fluorosilicon-modified multifunctional linseed oil-based UV-curable alkyd resin oligomer

[0036] Such as figure 1 As shown, it mainly includes the following steps:

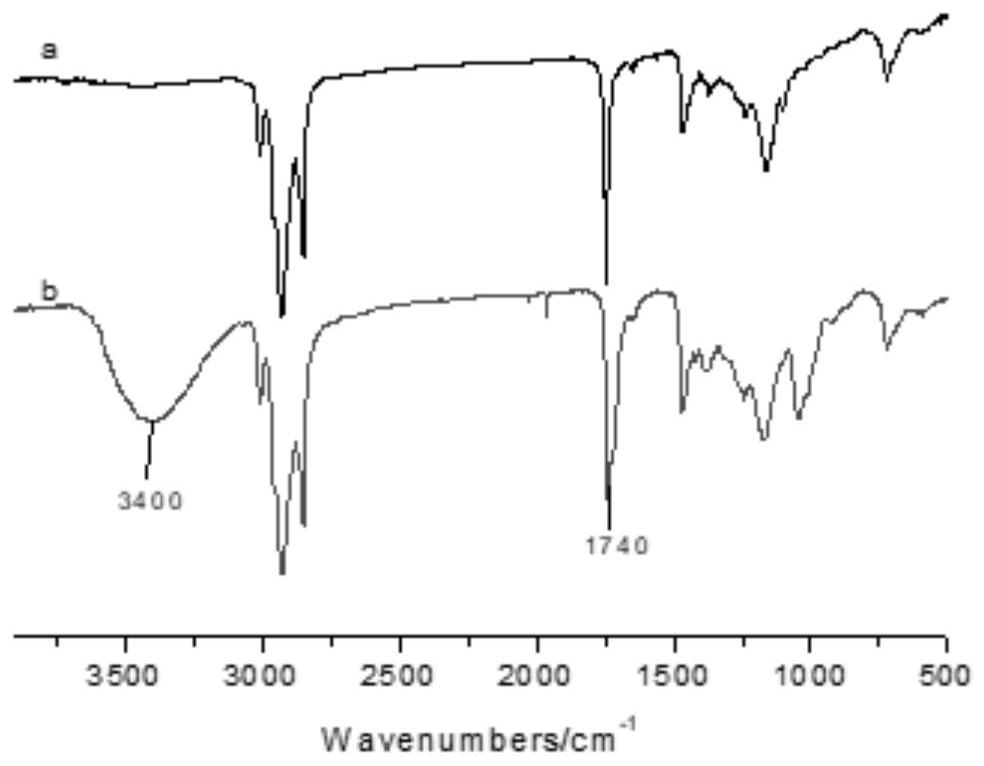

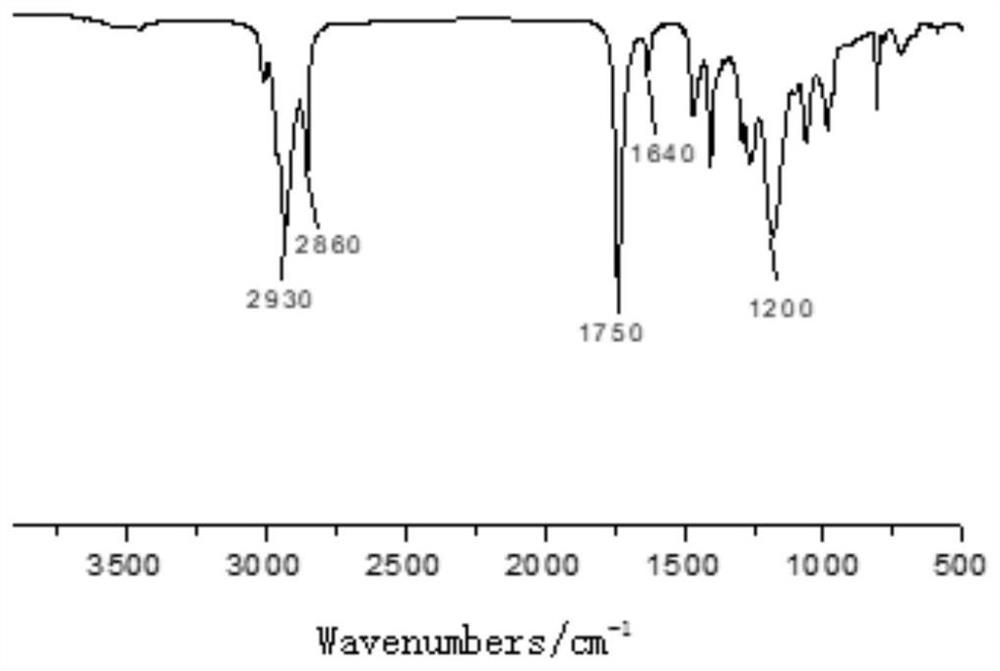

[0037] (1) Add 20g of refined linseed oil to a 250mL three-necked flask, install a mechanical stirrer, a spherical condenser, and a nitrogen port, add 6.2g of pentaerythritol, stir and heat up to 120°C, add 4wt% lithium hydroxide as a catalyst, and Nitrogen, react at 210°C for 3 hours until the ethanol tolerance is 5, add an appropriate amount of phosphoric acid to neutralize lithium hydroxide, and lower the temperature to obtain linseed oil-based polyol (intermediate product I). The FT-TR spectra of linseed oil and linseed oil polyols are as follows figure 2 As shown, its infrared characteristic absorption peak data is as follows: IR: 2950cm -1:-CH 3 Existence; 2860cm -1 :-CH 2 Existence; 1740cm -1 : linseed oil-C=O exists; 3400cm -1 :-OH exists.

[0038] (2) Cool the ...

Embodiment 2

[0044] 1. A preparation method of fluorosilicon-modified multifunctional linseed oil-based UV-curable alkyd resin oligomer

[0045] Such as figure 1 As shown, it mainly includes the following steps:

[0046] (1) Add 20g of refined linseed oil to a 250mL three-necked flask, install a mechanical stirrer, a spherical condenser, and a nitrogen port, add 6.8g of pentaerythritol, stir and heat up to 120°C, add 5% wt of lithium hydroxide as a catalyst, Nitrogen, react at 220°C for 2 hours until the ethanol tolerance is 5, add an appropriate amount of phosphoric acid to neutralize lithium hydroxide, and cool down to obtain linseed oil-based polyol (intermediate product I);

[0047] (2) The linseed oil-based polyol obtained above is lowered to about 150°C, and 10wt% of the reflux solvent xylene is added as a water-carrying agent, and 6.4g of isophthalic acid is added, and the temperature is raised to 190°C for 1 hour, and then heated to React at 225°C for 4 hours, stop the reaction w...

Embodiment 3

[0053] 1. A preparation method of fluorosilicon-modified multifunctional linseed oil-based UV-curable alkyd resin oligomer

[0054] Such as figure 1 As shown, it mainly includes the following steps:

[0055] (1) Add 20g of refined linseed oil to a 250mL three-necked flask, install a mechanical stirrer, a spherical condenser, and a nitrogen port, add 6.5g of pentaerythritol, stir and heat up to 120°C, add 4wt% lithium hydroxide as a catalyst, and Nitrogen, react at 240°C for 1.5h until the ethanol tolerance is 5, add an appropriate amount of phosphoric acid to neutralize lithium hydroxide, and cool down to obtain linseed oil-based polyol (intermediate product I);

[0056] (2) Lower the linseed oil-based polyol prepared above to about 150°C, add 8wt% reflux solvent xylene as a water-carrying agent, add 5.4g of isophthalic acid, heat up to 180°C, keep warm for 1h, and continue to heat up To 235°C, maintain this temperature for 3 hours until the acid value is lower than 0.5mgKOH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com