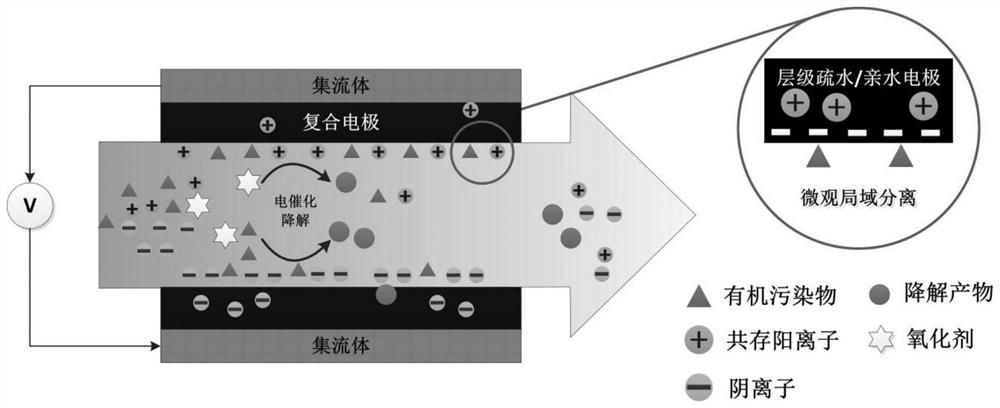

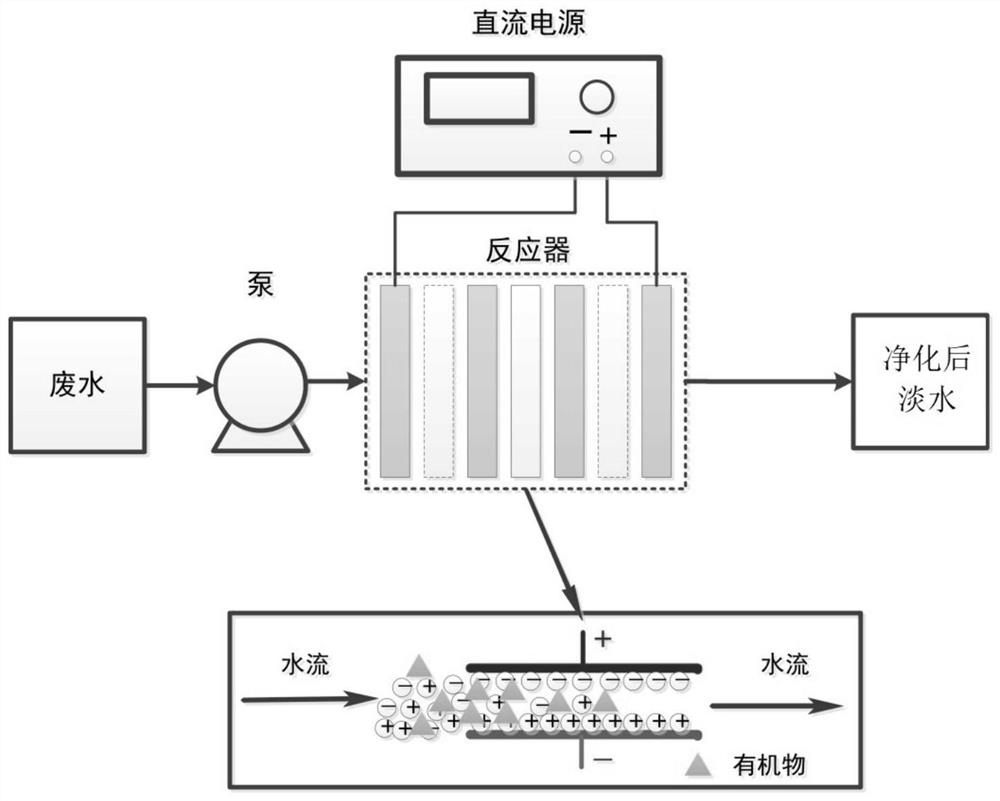

Method for synchronously removing salt and organic matters based on hierarchical hydrophobic/hydrophilic electrodes and device thereof

An organic and hydrophobic technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the limited effect of degrading organic matter, the removal efficiency of copper ions and citric acid needs to be further improved, electrode pollution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

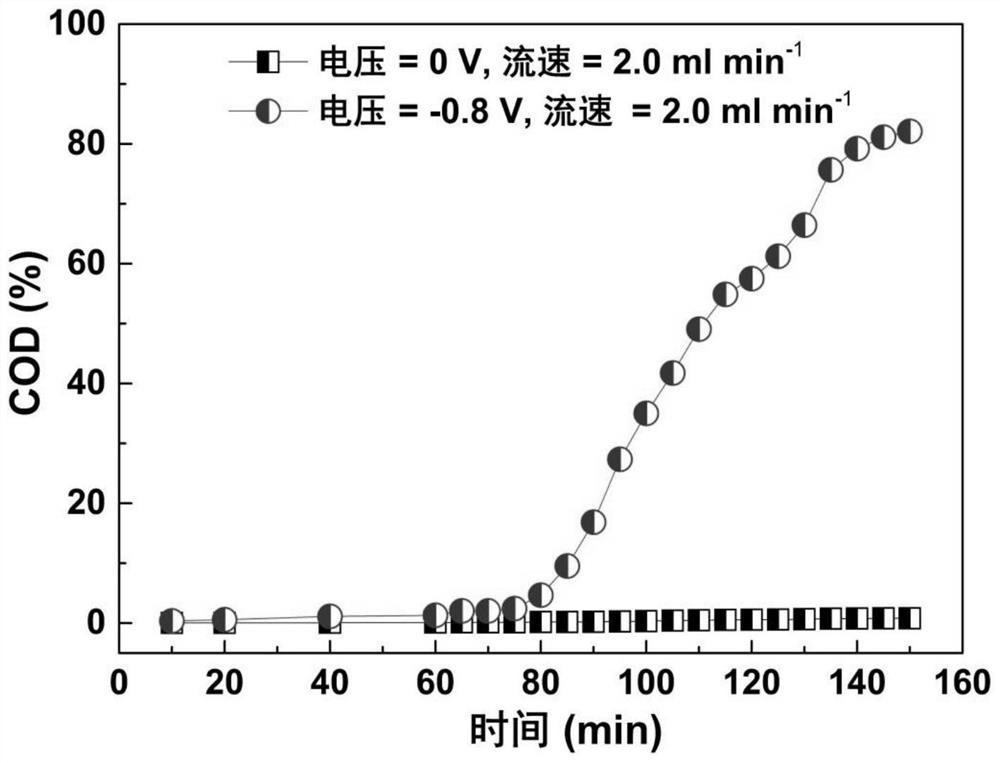

Examples

Embodiment 1

[0054] In this embodiment, the manufacturing steps of the capacitive deionization device are as follows:

[0055] 1. Preparation of porous composite materials

[0056] Add 1g of activated carbon material into 200mL of 5wt% hydrogen peroxide and soak for 1 hour at room temperature to obtain hydrophilic activated carbon;

[0057] Mix 0.5 g of hydrophilic activated carbon with 80 mL of MnSO at a concentration of 0.1 mol / L 4 Mix the solutions, transfer them into a hydrothermal reaction kettle after mixing evenly, take them out after reacting at 110°C for 12 hours, wash the crude material obtained, and obtain a porous composite material precursor (powder) after drying;

[0058] Take 200mL of deionized water containing 0.01g γ-MPS, adjust its pH to 8.5 with ammonia water, then add 0.6g of porous composite material precursor to it, then stir at a stirring speed of 500r / min for 1h, then centrifuge, and The obtained solid product was washed three times with distilled water, and then ...

Embodiment 2

[0072] The difference between this example and Example 1 is that 0.1mol / L CoCl 2 Solution replaces 0.1 mol / L MnSO 4 Solution, other conditions and process are all identical with embodiment 1, and its treatment effect is similar to embodiment 1.

Embodiment 3

[0074] The difference between this embodiment and embodiment 1 is that 0.1mol / L NiCl 2 Solution replaces 0.1 mol / L MnSO 4 Solution, other conditions and process are all identical with embodiment 1, and its treatment effect is similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com