A multi-bacteria fusion symbiotic fermentation process for disease resistance and growth promotion

A symbiotic fermentation and process technology, which is applied in the field of multi-bacteria fusion symbiotic fermentation process, can solve the problems of high process cost and single colony, and achieve the effects of increasing dissolved oxygen, diversifying bacterial flora, and shortening the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

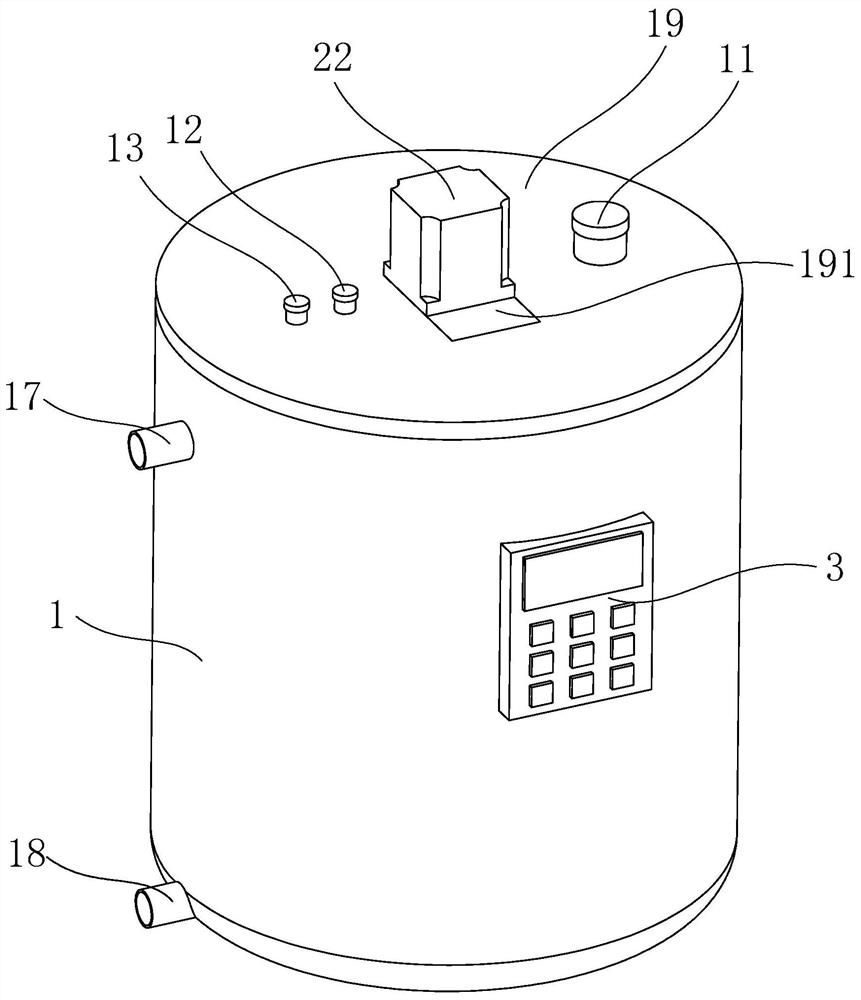

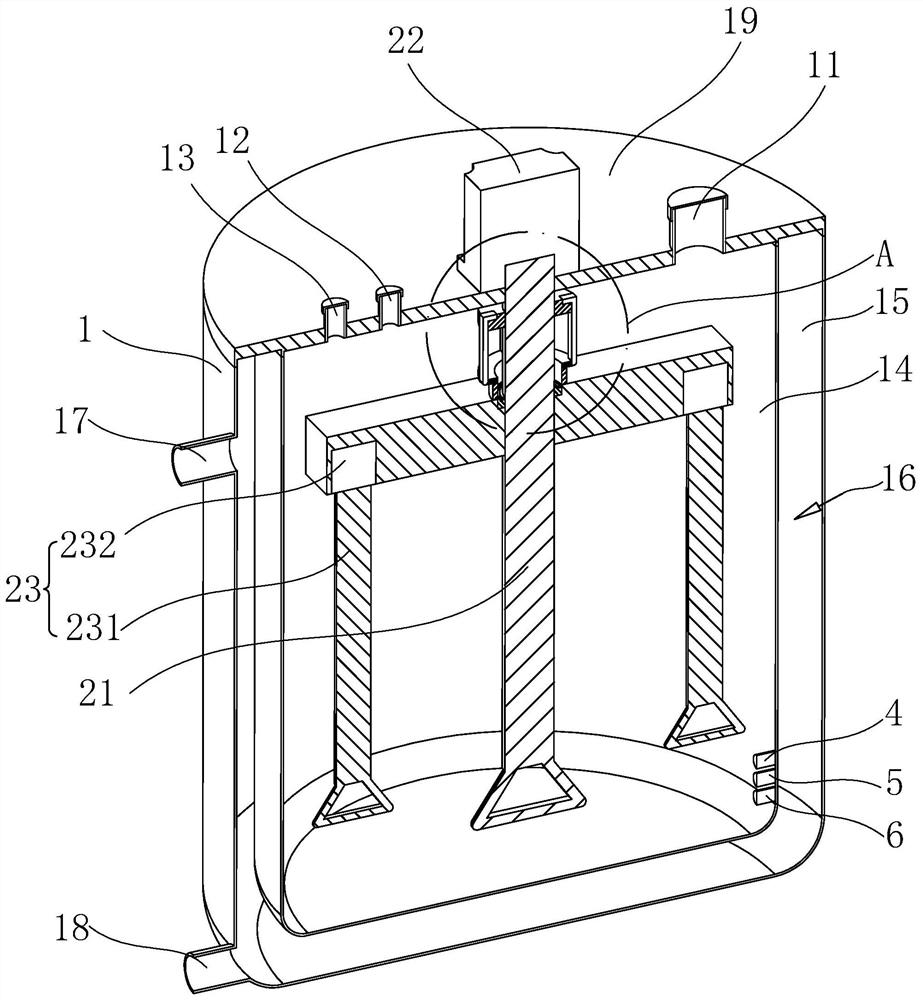

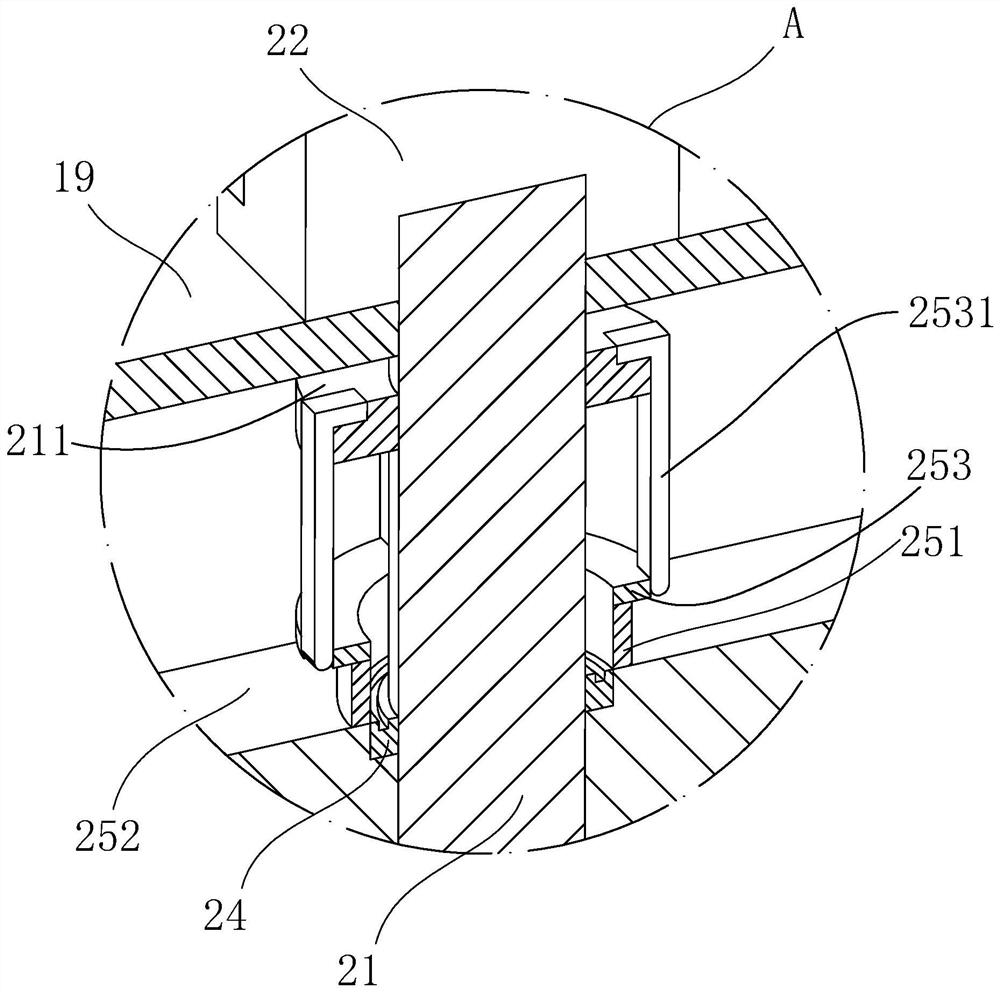

Image

Examples

Embodiment 1

[0054] A multi-bacteria fusion symbiotic fermentation process for disease resistance and growth promotion, comprising the following steps:

[0055] Step (1-1), configuration culture medium:

[0056] Configure medium A: Weigh 3g beef extract, 10g peptone, 5g sodium chloride and 20g agar, add to distilled water, mix well, and add distilled water to make the system 1000mL, adjust the pH value to 7.2, and then in the temperature of 121℃ , and sterilized for 30 minutes under the condition of a pressure of 0.10 MPa to prepare medium A.

[0057] Prepare medium B: Weigh 200g of potato filtrate, 20g of glucose and 20g of agar, add them to distilled water, mix well, and add distilled water to make the system 1000mL, then sterilize for 30min at a temperature of 121°C and a pressure of 0.10MPa , to prepare medium B.

[0058] Configure medium C: weigh 10g peptone, 12g beef extract, 5g yeast extract, 20g glucose, 5g sodium acetate, 2g diamine citrate, 1.0g Tween-80, 2.0g dipotassium hydro...

Embodiment 2

[0065] The difference between this embodiment and the above-mentioned embodiment 1 lies in: the condition parameter changes in the fusion symbiotic fermentation process in step (2).

Embodiment 3

[0067] The difference between this embodiment and the above-mentioned embodiment 1 lies in: the condition parameter changes in the fusion symbiotic fermentation process in step (2).

[0068] The conditional parameters in above-mentioned embodiment 1-3 are as shown in table 1 below:

[0069] The condition parameter table of multi-bacteria fusion symbiotic fermentation in the embodiment 1-3 of table 1

[0070]

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com