A kind of preparation method of magneto-optical glass-based periodic nanoporous magnetic plasmonic sensor

A technology of magneto-optical glass and nanopores, which is applied in the fields of instruments, scientific instruments, and material analysis through optical means, can solve the problems of enhanced interaction, broadened spectrum, reduced spectral resolution, and large sensor volume, and achieves improved Magneto-optical properties of the system, good magnetism and low absorption, and the effect of increasing spectral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

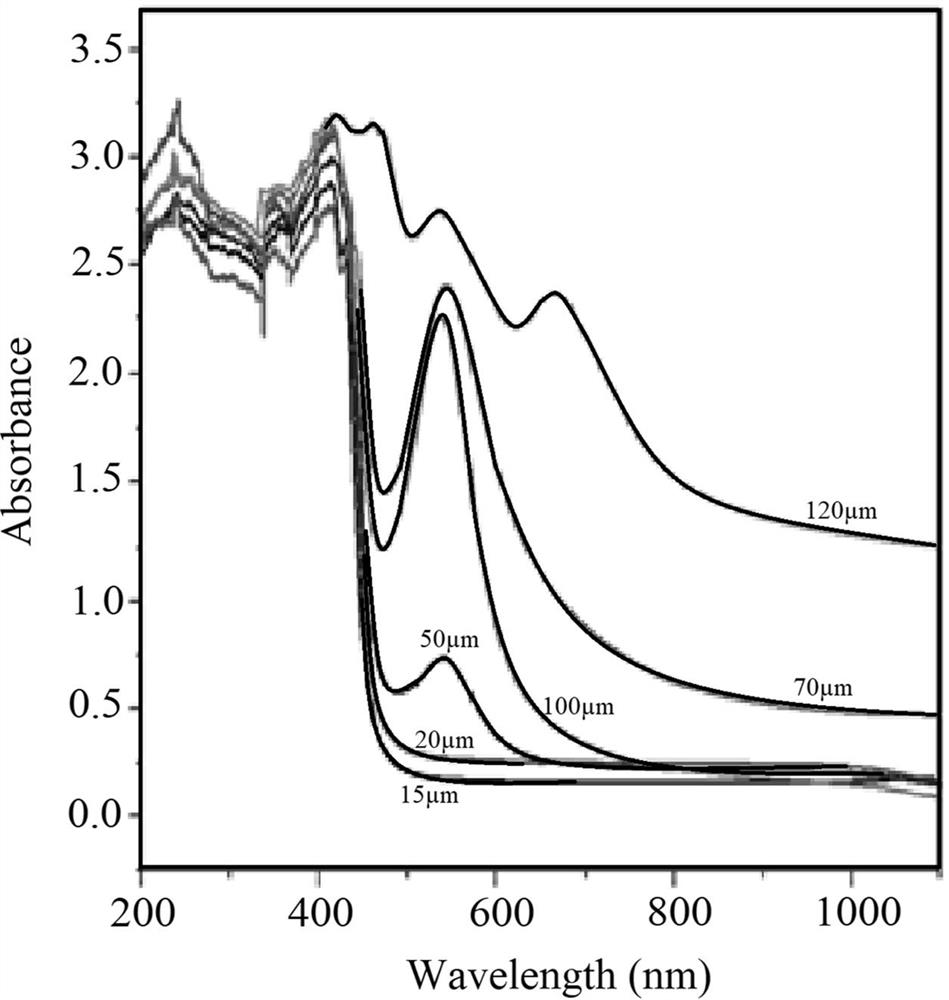

[0029] 1) Preparation of magneto-optical glass prism: according to 35Bi 2 O 3 -45PbO-10H 3 BO 3 -5GeO 2 Molar ratio of -5BaO weighed glass raw material, stirred at 900 ℃ N 2 After being melted for 1 hour, cast into a prism shape, annealed at 350 °C for 3 hours, and optically polished the upper surface of the glass prism to achieve surface roughness 7;

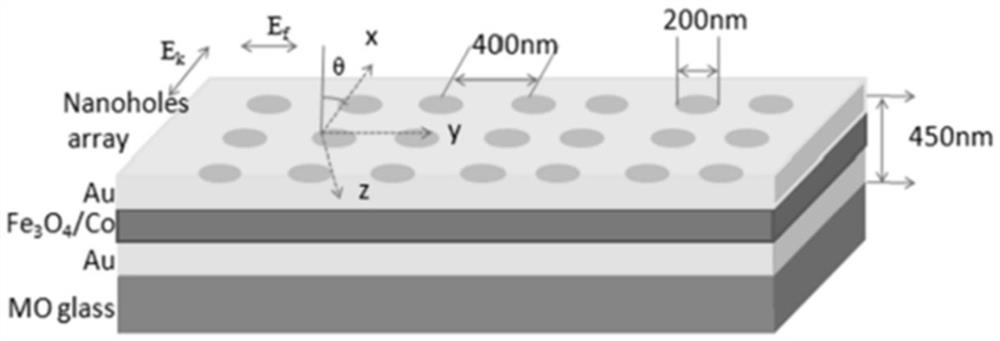

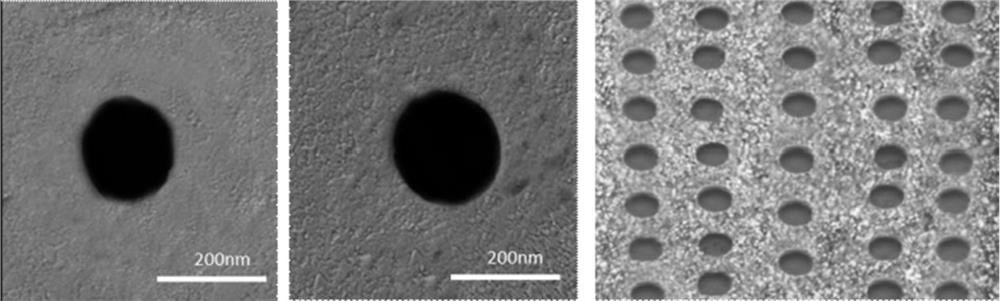

[0030] 2) A multilayer film structure was prepared on the upper surface of the magneto-optical glass prism: the upper surface of the magneto-optical glass prism was cleaned with deionized water and then purged with ammonia gas for 2 minutes. The pressure before deposition was 8.0×10 -5 Pa, then transfer the magneto-optical glass prism to the magnetron sputtering vacuum chamber, fill with Ar gas to make the total pressure reach 0.6 Pa, the power is 60W, and the temperature is 150°C to sputter the gold target, and after 12 hours, it is naturally cooled to room temperature to obtain A gold film with a thickness of 150 nm, th...

Embodiment 2

[0035] 1) Preparation of magneto-optical glass prism: according to 40Bi 2 O 3 -40PbO-10H 3 BO 3 -3GeO 2 -7BaO molar ratio weighed glass raw material, stirred at 950℃ N 2 After being melted for 1 hour, cast into a prism shape, annealed at 300 °C for 2 hours, and optically polished the upper surface of the glass prism to achieve surface roughness 7;

[0036] 2) A multilayer film structure was prepared on the upper surface of the magneto-optical glass prism: the upper surface of the magneto-optical glass prism was cleaned with deionized water and then purged with ammonia gas for 3 minutes, and the pressure before deposition was 6.0×10 -5 Pa, then transfer the sample to the magnetron sputtering vacuum chamber, fill with Ar gas to make the total pressure reach 0.6 Pa, the power is 60W, and the temperature is 120°C for sputtering the gold target. After 12 hours, it is naturally cooled to room temperature to obtain a thickness of 120nm. the gold film, then replace the sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com