Junction field effect transistor based on tungsten disulfide/gallium antimonide and preparation method thereof

A field-effect transistor, junction technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of low defect state density, poor subthreshold swing, high dielectric constant, etc., to suppress interface defects The effect of producing, reducing impact, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

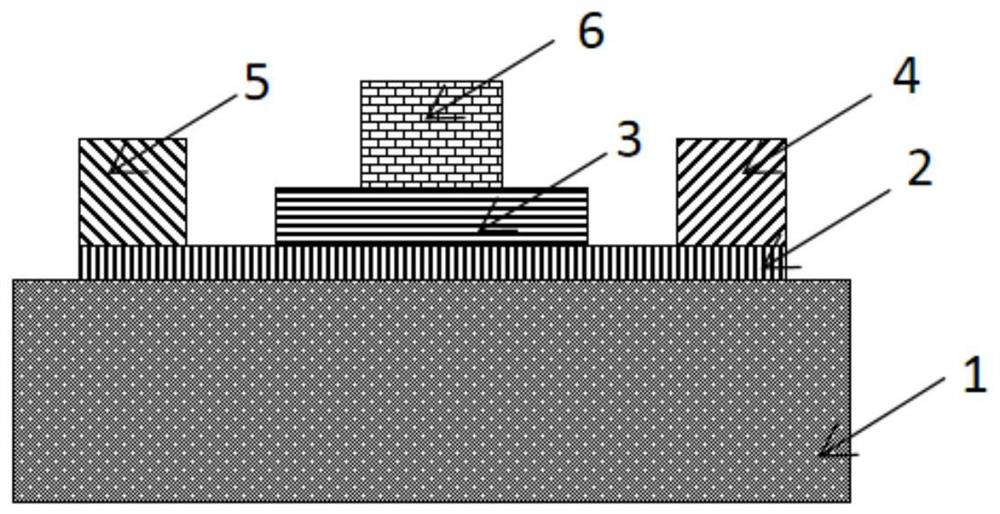

[0038] WS-based 2 The preparation method of GaSb junction field effect transistor, concrete steps are as follows:

[0039] Step 1: Select a thermally oxidized silicon wafer as the substrate, first use ethanol, acetone, and deionized water to ultrasonicate for 5 minutes, then heat-treat the substrate on a heating platform at 300°C for 1 hour, and store it in a dry environment;

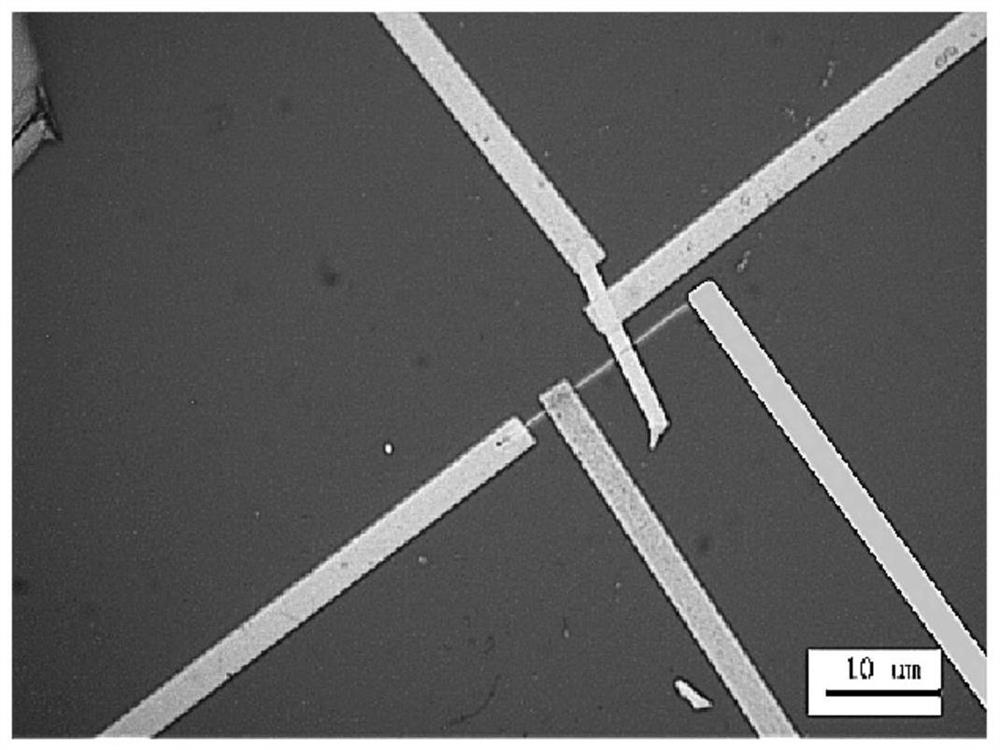

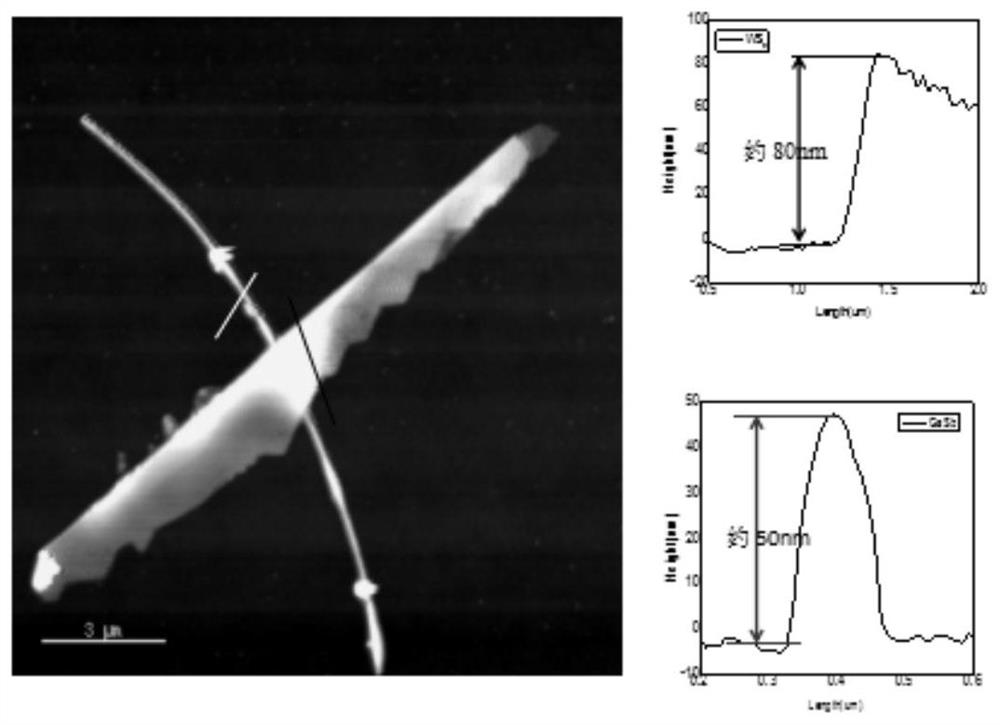

[0040] Step 2: Immerse the P-type GaSb nanowires grown on the glass substrate in anhydrous ethanol for 10-15s to disperse them, drop the dispersed liquid on the surface of the substrate, first spin-coat at 600rpm for 8 seconds, and then spin-coat at 2000rpm Coated for 50 seconds to obtain the desired P-type GaSb nanowires on the substrate surface.

[0041] Step 3: Attach a smooth-surfaced PDMS membrane on the upper surface of the glass slide and prepare the N-type WS membrane obtained by mechanical exfoliation 2 Adhesive tape for thin film samples, stick the tape tightly on the PDMS membrane to make N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com