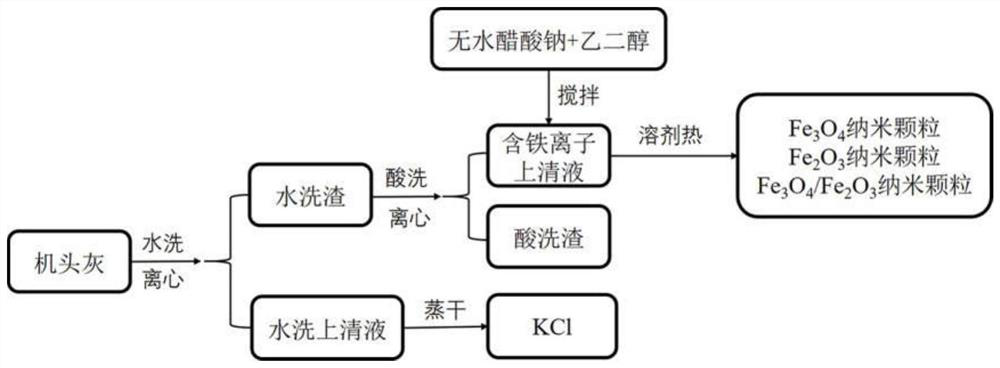

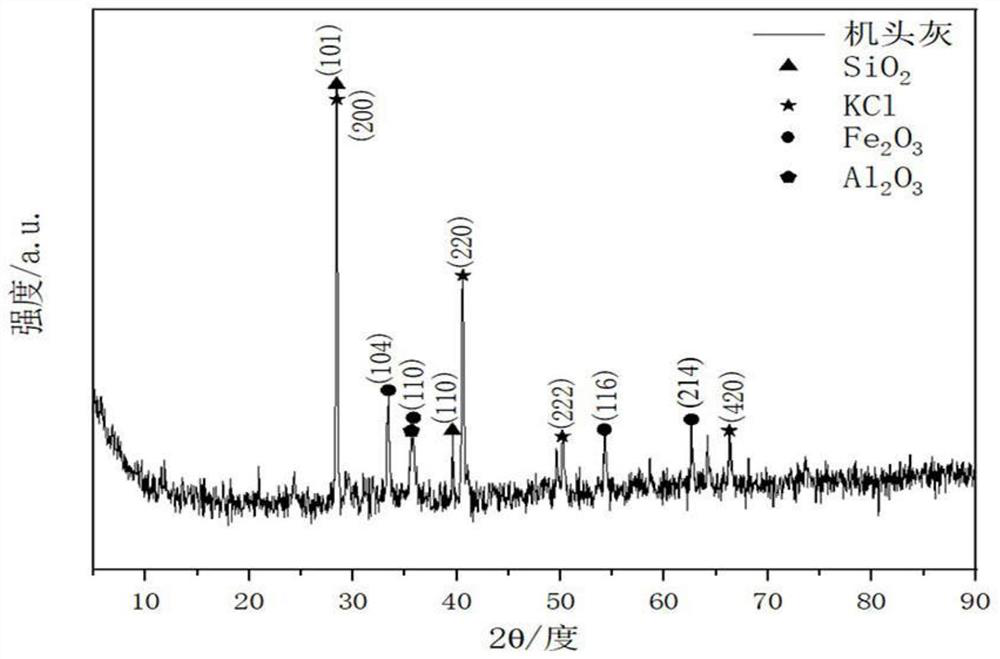

Method for preparing functional iron oxide nanoparticles by taking machine head ash as raw material

A technology of iron oxide and nano particles, which is applied in the field of nano materials, can solve the problems of insufficient development of high value-added products, and achieve the effect of high functional application and added value, good crystallization and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

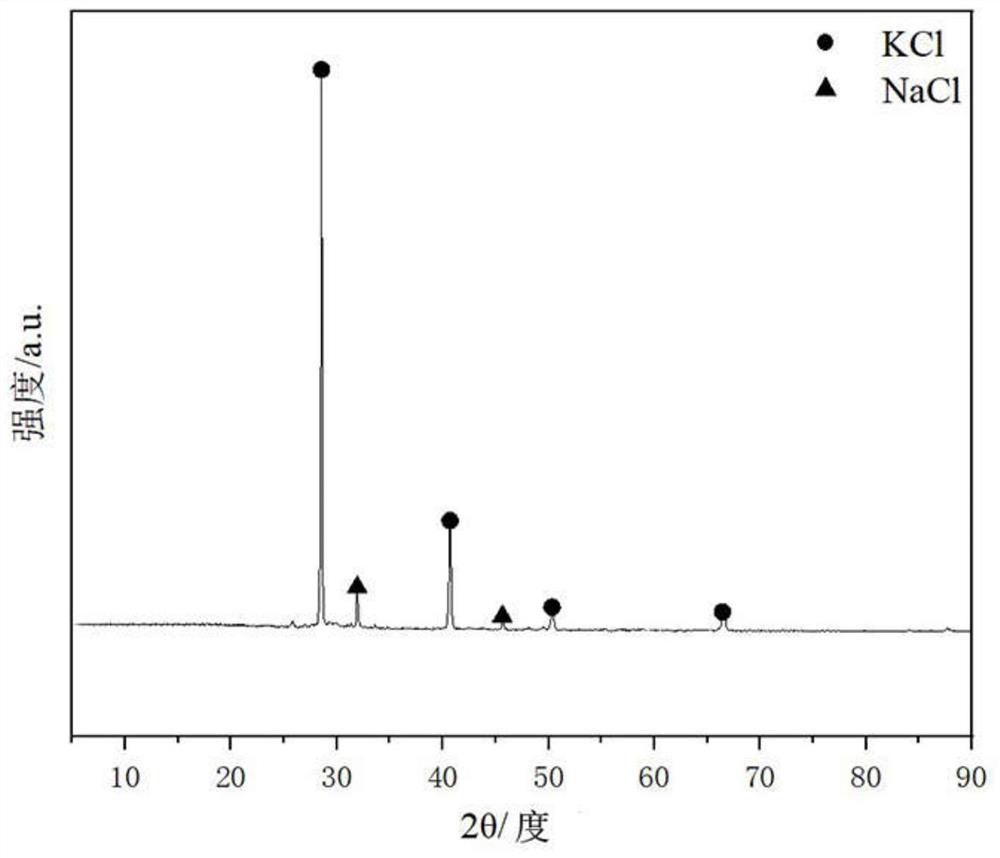

Embodiment 1

[0064] Weigh 5g of machine head ash, add ultrapure water to wash, the solid-to-liquid ratio of machine head ash and ultrapure water is 1:8, stir thoroughly and ultrasonically for 30min, then collect the water-washed slag precipitate by centrifugation at 4000rpm, and evaporate the water-washed supernatant to dryness Collect the powder. Add 4.5 mol / L hydrochloric acid to the washed slag precipitate according to the solid-to-liquid ratio of 1:5, stir at 90°C for 90 min, and then collect the supernatant by centrifugation at 4000 rpm, which is designated as solution A. Use NaOH solution to adjust the pH of solution A to 1.3, add ethylene glycol to make the iron ion concentration in solution A 0.0058mol / L, take a certain amount of anhydrous sodium acetate and dissolve it in ethylene glycol to make the concentration 0.0294mol / L According to the volume ratio of 1:1, mix solution A and sodium acetate ethylene glycol solution, stir at room temperature for 30 minutes until uniform, and f...

Embodiment 2

[0068] Weigh 10g of machine head ash, add ultrapure water to wash, the solid-to-liquid ratio of machine head ash and ultrapure water is 1:8, stir thoroughly and ultrasonically for 30min, then collect the water-washed slag precipitate by centrifugation at 4000rpm, and evaporate the water-washed supernatant to dry up powder. According to the solid-liquid ratio of 1:5, add 3 mol / L hydrochloric acid to the washed slag precipitate, stir at 85°C for 90 minutes, and then collect the supernatant by centrifugation at 4000rpm, and record it as solution A. Use NaOH solution to adjust the pH of solution A to 1.3, add ethylene glycol to make the iron ion concentration in solution A 0.0143mol / L, take a certain amount of anhydrous sodium acetate and dissolve it in ethylene glycol to make the concentration 0.0714mol / L Mix solution A and sodium acetate ethylene glycol solution at a volume ratio of 1:2, and stir at room temperature for 30 minutes until uniform to form a mixed solution B. The m...

Embodiment 3

[0072] Weigh 5g of machine head ash, add ultrapure water to wash, the solid-to-liquid ratio of machine head ash to ultrapure water is 1:6, stir thoroughly and ultrasonically for 30min, and then collect the water-washed slag precipitate by centrifugation at 4000rpm. Add 4.5 mol / L sulfuric acid to the water-washed slag precipitate according to the solid-to-liquid ratio of 1:10, stir at 40°C for 120 min, and then collect the supernatant by centrifugation at 4000 rpm, which is designated as solution A. Use NaOH solution to adjust the pH of solution A to 1.8, add ethylene glycol to make the iron ion concentration in solution A 0.0083mol / L, take a certain amount of anhydrous sodium acetate and dissolve it in ethylene glycol to make the concentration 0.0416mol / L Mix solution A and sodium acetate ethylene glycol solution at a volume ratio of 1:3, and stir at room temperature for 30 minutes until uniform to form a mixed solution B. The mixed solution B was transferred into the reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com