Polyhedral oligomeric silsesquioxane (POSS)-containing alpha-amino triethoxy silane as well as preparation method and application thereof

A technology of aminotriethoxysilane and chloromethyltriethoxysilane, which is applied in the field of organosilicon synthesis, can solve the problems of high cost, complicated chemical method, etc., and achieves great application value, simple separation steps, and reaction temperature. Easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

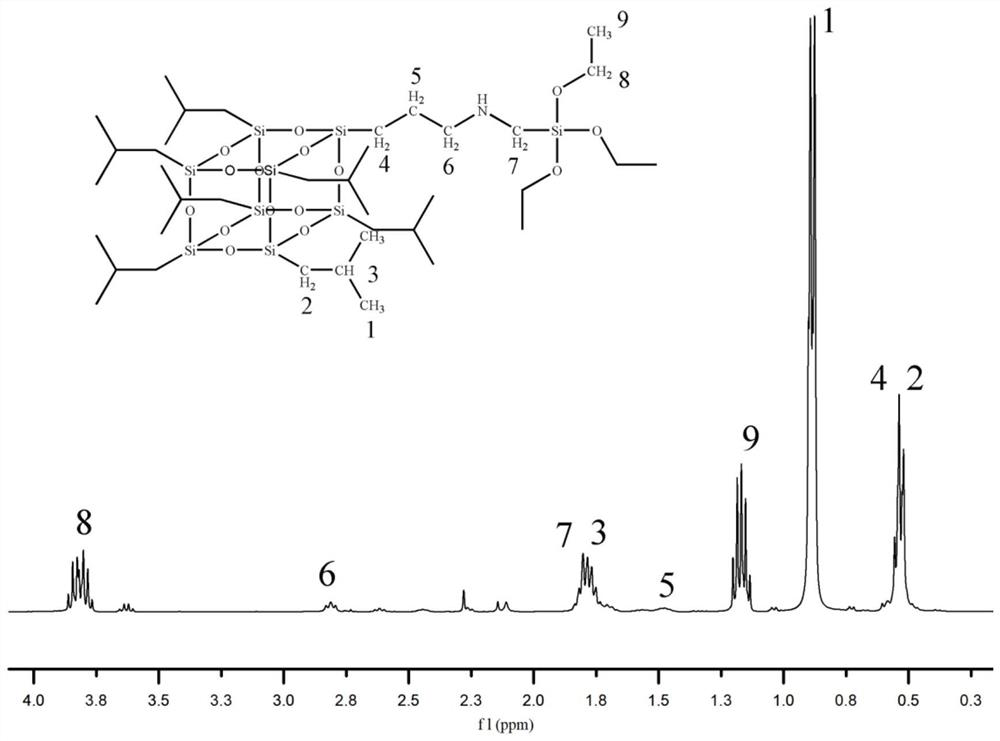

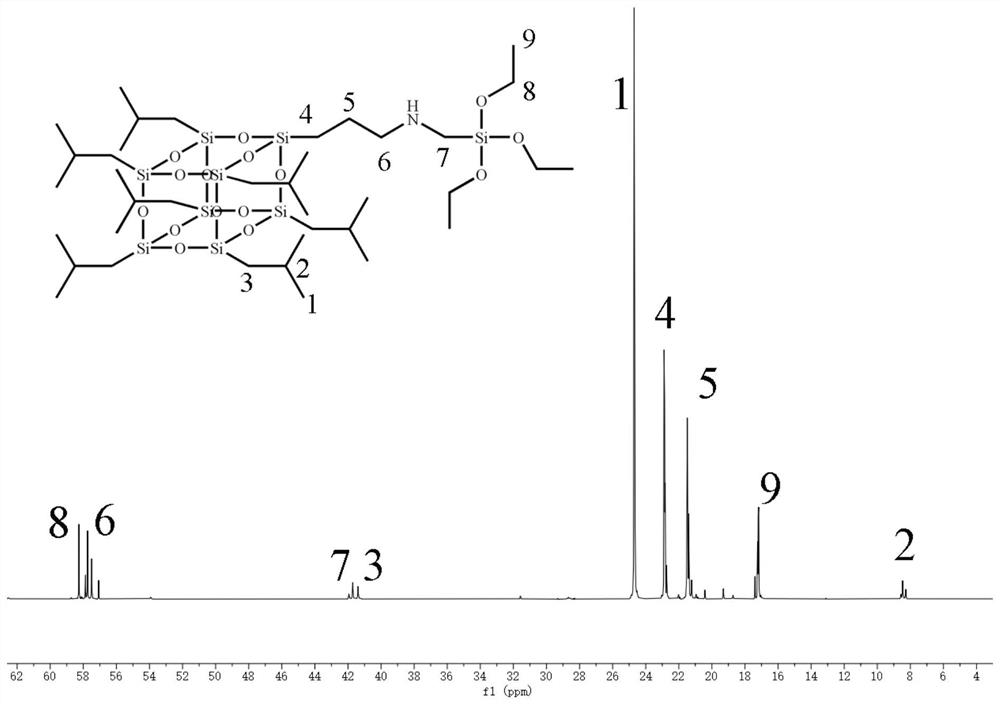

Examples

Embodiment 1

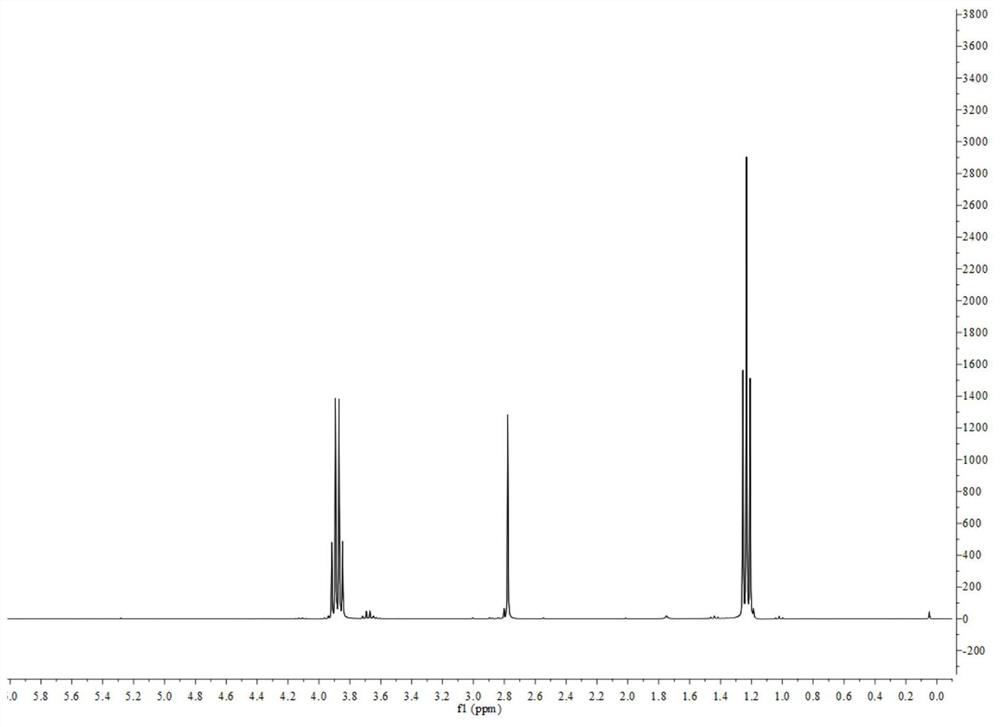

[0069] Preparation of Chloromethyltriethoxysilane

[0070] Add 36.036g of urea and 150ml of petroleum ether into a 250ml three-neck round-bottom bottle, connect a spherical condenser and two constant pressure dropping funnels to the bottle mouth, and put 27.642g of ethanol (after anhydrous treatment) and 30.000g of chlorine under the protection of nitrogen. Methyltrichlorosilane was added to two constant pressure dropping funnels respectively. Under the protection of nitrogen, heat and stir the mixture of urea and petroleum ether to 65°C, then add ethanol and chloromethyltrichlorosilane synchronously at a rate of 1 drop / second; The reaction was stirred at ℃ for 5h. After the reaction, filter the reaction solution to remove insoluble viscous matter; heat the obtained filtrate to 90°C to remove petroleum ether and ethanol, and recover the obtained petroleum ether and ethanol; heat the remaining liquid to 70°C under a vacuum of 10mmHg , the transparent liquid was distilled off ...

Embodiment 2

[0085] The final product of embodiment 1 is used as the crosslinking agent of room temperature vulcanized silicone rubber

[0086] Take three groups of 3g hydroxy silicone oil with a molecular weight of 3000 (hydroxyl content 0.002mol), add 3ml of toluene respectively and stir evenly, then place them in the mold, mix the hydroxyl group in the hydroxy silicone oil with the α-aminotriethoxysilane containing POSS The molar ratios are 1:1, 1:0.5, 1:0.33 respectively, weigh 2.1g (0.002mol), 1.05g (0.001mol), 0.7g (0.00066mol) 1-(3-(α-N -Methyltriethoxysilyl))propyl heptaisobutyl POSS, put into toluene and dissolve respectively, after dissolving in toluene solvent, add dropwise into hydroxyl silicone oil and stir quickly to mix evenly, at 20 ℃, 45% Cross-linking and curing are carried out under humidity.

[0087] The tack-free time of the cross-linked hybrid system was determined by the finger touch method. The surface dry time of the silicone oil in the 1:1 ratio group was 40 min...

Embodiment 3

[0092] The final product of embodiment 1 is used as reinforcing curing agent to epoxy resin E44 reinforcing curing

[0093] Dissolve 3 groups of 2g epoxy resin E44 in the toluene solvent in the single-necked round bottom flask respectively, add 1.6g, 0.8g, 0.533g of 1-(3-(α-N-methyltriethoxysilyl ))Propyl heptaisobutyl POSS, that is, the molar ratios of epoxy resin E44 and α-aminotriethoxysilane containing POSS are 1:1, 1:0.5, 1:0.333, respectively, and the opening of the single-necked round bottom flask Connect the drying tube at the place, then heat to 100°C under magnetic stirring, and react for 24h. After the reaction, the toluene was removed by vacuum distillation (vacuum degree 80 mmHg, heated to 60° C.), and the residue was a white to pale yellow resinous solid. After sampling the three groups of cross-linked cured substances, perform TGA characterization together with the epoxy resin E44 sample cured by 4-4 diaminodiphenylmethane (ie DDM), and compare their thermal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com