Preparation method of medical titanium alloy

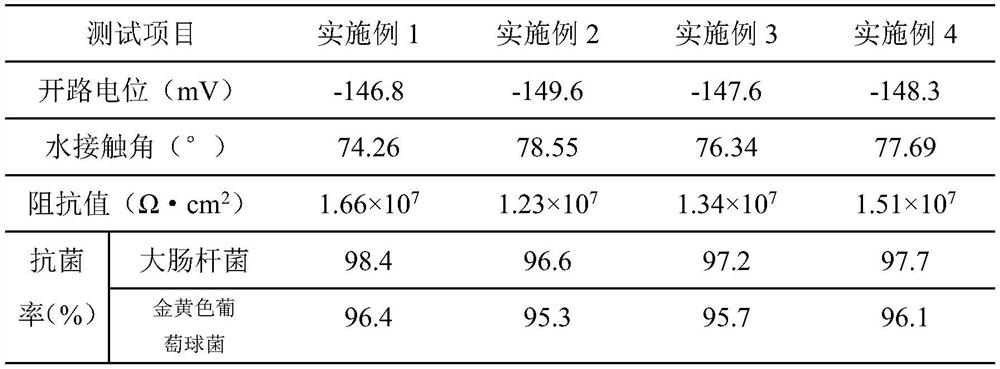

A technology of titanium alloy and titanium metal, applied in the field of preparation of medical titanium alloy, can solve the problems of no antibacterial properties on titanium surface, low bone conductivity, failure of implantation operation, etc., and achieve excellent corrosion resistance, excellent antibacterial rate, good The effect of the hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Method for preparing medical titanium alloys, including the following steps:

[0014] S1: The mass percentage of 72% titanium powder, 22.4% tantalum metal powder, 1.6% iron metal powder and 4% silver metal powder were mixed into the vacuum ball mill, and the ball mill was vacuumped after 3.5 hours. 9Pa, then rush into argon, so repeated three times to ensure no air in the vacuum ball grinding, where the vacuum ball mill ball is rotational speed at 160r / min, the ball milling time is 22 h,

[0015] S2: Place the mixed metal powder obtained by step S1 in the graphite crucible, sintering on the discharge plasma sintering system, first rising from 10 ° C / min to 500 ° C from the room temperature to the sintering temperature, then heat insulation 5min The temperature rise rate is 1.5 ° C / min, and the junction temperature is 880 ° C, the sintering time is 25 min, and the pulse current is opened for 1.5 min every 5 minutes during the sintering process, and the axial pressure o...

Embodiment 2

[0017] Method for preparing medical titanium alloys, including the following steps:

[0018] S1: The mass percentage of 75% titanium powder, 20% tantalum metal powder, 1.5% iron metal powder and 3.5% silver metal powder were mixed into the vacuum ball mill, and the ball milling tank was pumped after 5 h after ball milling. Vacuum to 12PA, then rush into argon, so repeated three times to ensure no air in the vacuum ball grinding; there is a vacuum ball mill ball milling at 220 r / min, the ball milling time is 30 h,

[0019] S2: Place the mixed metal powder obtained by step S1 in the graphite crucible, sintering on the discharge plasma sintering system, raised from the room temperature to the sintering temperature first with the temperature rise rate of 15 ° C / min to 600 ° C, heat insulation 8min The temperature increase of 3 ° C / min to the sintering temperature, the junction temperature is 920 ° C, the sintering time is 50 min, and the pulse current is opened every 5 minutes d...

Embodiment 3

[0021] Method for preparing medical titanium alloys, including the following steps:

[0022] S1: The mass percentage of 70% titanium powder, 23.6% tantalum metal powder, 2% iron metal powder and 4.4% silver metal powder were mixed into the vacuum ball mill, and the ball milling tank was pumped after the ball milling for 4 h Vacuum to 10 Pa, then rush into argon, so repeated three times to ensure no air in the vacuum ball grinding; there is a vacuum ball mill ball milling at 200R / min, ball milling time is 25h,

[0023] S2: Place the mixed metal powder obtained by step S1 in the graphite crucible, sintering on the discharge plasma sintering system, raised from the room temperature to the sintering temperature, then rose the temperature rise rate of 12 ° C to 550 ° C, after holding 6 minutes The temperature rise rate of 2 ° C / min is warmed to the sintering temperature, the junction temperature is 900 ° C, the sintering time is 40 min, and the pulse current is opened every 5 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com