Kitchen waste fermentation method based on pure oxygen fermentation and hydrogen-rich static natural decomposition, and fermentation product and application thereof

A technology of kitchen waste and fermentation method, which is applied in application, microbial treatment, climate change adaptation and other directions, can solve the problems of difficult treatment of high-concentration odor, reduced decomposition power, energy loss, etc., so as to save the odor control link. And the effect of capital investment, activity and enzyme production capacity improvement, and effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

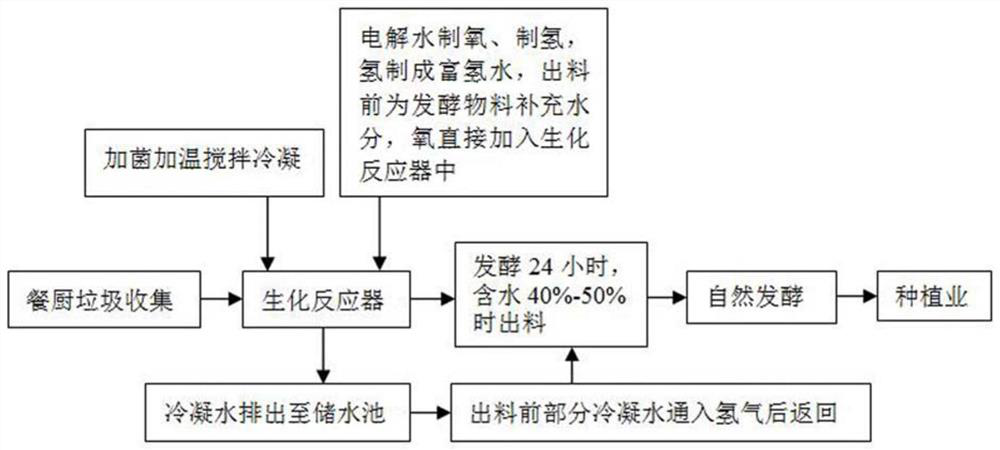

[0041] A food waste fermentation method based on pure oxygen fermentation and hydrogen-rich static natural decomposition, the steps are as follows:

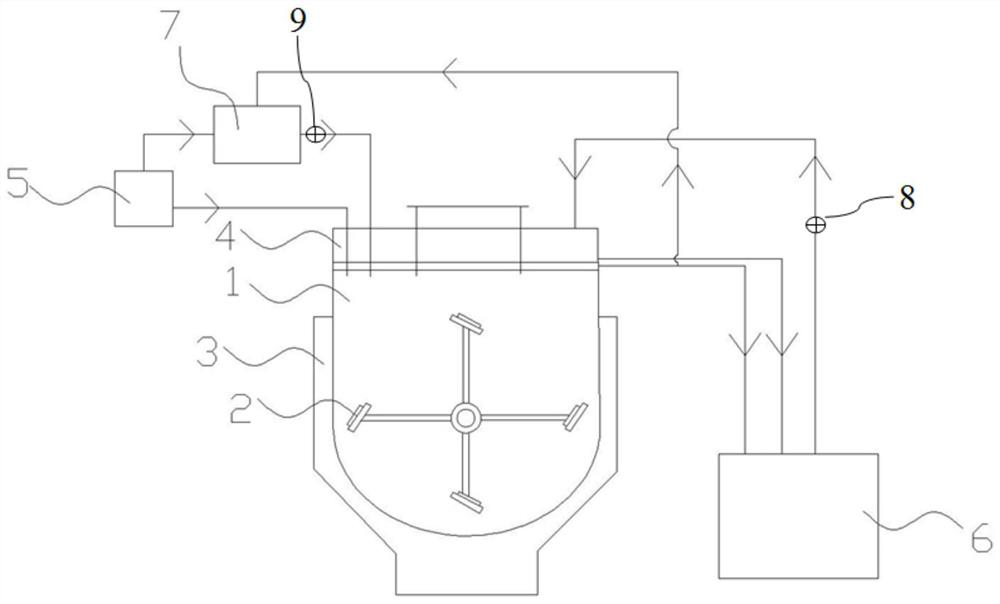

[0042] see figure 2 and image 3 0.4 tons of food waste without crushing, rinsing, extrusion, dehydration, desalination and degreasing, and with a moisture content of 80% were directly put into biochemical reactor 1 with a capacity of 1 ton, and then 5 wt.% of high-temperature-resistant Wo For strain No. 4, turn on heater 3, agitator 2, condenser 4, and electrolytic water oxygen production and hydrogen production device 5 for aerobic fermentation. The temperature of fermentation is controlled at 65°C, and the speed of agitator 2 is controlled at 10 rpm , the oxygen production capacity of the electrolytic water oxygen production and hydrogen production device 5 is 2L / min, the hydrogen production capacity is 4L / min, and the discharge of condensed water is 6.3 kg / hour. The prepared hydrogen is injected into the condensed water sto...

Embodiment 2

[0044] A food waste fermentation method based on pure oxygen fermentation and hydrogen-rich static natural decomposition, the steps are as follows:

[0045] see figure 2 and image 3 , put 0.8 tons of food waste without crushing, rinsing, extrusion, dehydration, desalination and degreasing, with a moisture content of 70% directly into biochemical reactor 1 with a capacity of 1 ton, and then add 10% of the total weight of food waste The high-temperature-resistant Werner No. 4 strain is used, and the heater 3, agitator 2, condenser 4 and electrolytic water oxygen production and hydrogen production device 5 are turned on for aerobic fermentation. The fermentation temperature is controlled at 60°C, and the speed of the agitator is controlled at 15 rpm. / min, the oxygen production capacity of the electrolytic water oxygen production and hydrogen production device 5 is 3L / min, the hydrogen production capacity is 6L / min, the condenser is a water-cooled air-cooled composite condense...

Embodiment 3

[0047] A food waste fermentation method based on pure oxygen fermentation and hydrogen-rich static natural decomposition, the steps are as follows:

[0048] see figure 2 and image 3 , put 0.5 tons of food waste without crushing, rinsing, extrusion, dehydration, desalination and degreasing, with a moisture content of 60% directly into the biochemical reactor 1 with a capacity of 1 ton, and then add 8% of the total weight of food waste The high-temperature-resistant Werner No. 4 strain is used, and the heater 3, agitator 2, condenser 4 and electrolytic water oxygen production and hydrogen production device 5 are turned on for aerobic fermentation. The fermentation temperature is controlled at 62°C, and the speed of the agitator is controlled at 12 rpm. / min, the oxygen production capacity of the electrolytic water oxygen production and hydrogen production device 5 is 4L / min, the hydrogen production capacity is 8L / min, and the discharge of condensed water is 6.25kg / hour, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com