A kind of am50a die-casting magnesium alloy with excellent corrosion resistance oxide film and its preparation method

An AM50A, corrosion-resistant technology, applied in the field of magnesium alloy material preparation, can solve the problems of difficult handling, non-self-healing, weak bonding ability, etc., to achieve the effect of expanding application, slowing down corrosion rate, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

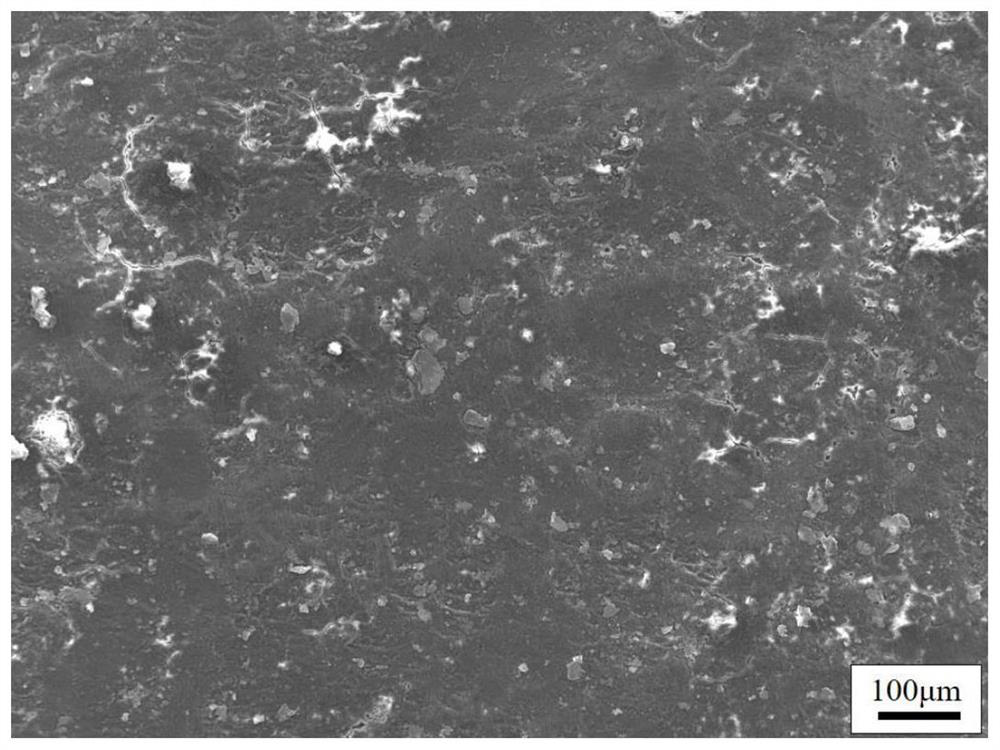

[0031] A kind of AM50A die-casting magnesium alloy with excellent corrosion resistance oxide film, its preparation method is as follows:

[0032] (1) adopt the method for automatic spraying mold release agent, with mold release agent (according to percentage by weight, it is made up of silicone oil 11%, base oil (simethicone) 7%, synthetic / wax (paraffin) 4%, additive ( Fatty alcohol polyoxyethylene ether) 2%, and the rest is ultrapure water) on the die-casting mold of magnesium-manganese alloy AM50A to carry out uniform dispersion spraying (the relevant parameters in the spraying process are: spraying time 2s, spraying distance is 200mm, mold after spraying The temperature is controlled at 220°C), and a high-temperature oxide layer with a thickness of 1.4 μm is formed on the manganese-magnesium alloy AM50A;

[0033] (2) The magnesium-manganese alloy AM50A with the high-temperature oxide layer on the surface in step (1) is directly exposed to the air for surface oxidation, and ...

Embodiment 2

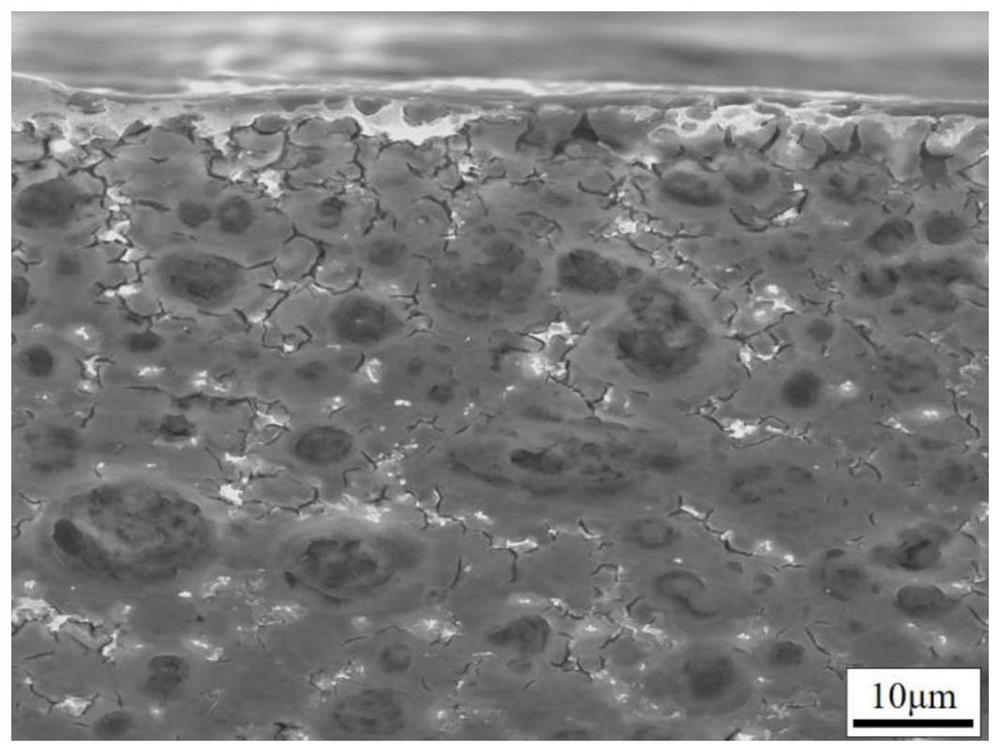

[0035] A kind of AM50A die-casting magnesium alloy with excellent corrosion resistance oxide film, its preparation method is as follows:

[0036] (1) Adopt the method of automatic spraying mold release agent, mold release agent (according to percentage by weight, it is made up of silicone oil 13%, base oil (polydimethylsiloxane liquid) 9%, synthetic / wax (stearic acid ) 6%, additive (fatty alcohol polyoxyethylene ether) 4%, and the rest is water) on the die-casting mold of magnesium-manganese alloy AM50A to carry out uniform dispersion spraying (the relevant parameters in the spraying process are: spraying time 5s, spraying distance is 100mm , the mold temperature is controlled at 140°C after spraying), and a high-temperature oxide layer with a thickness of 2.7 μm is formed on the manganese-magnesium alloy AM50A;

[0037] (2) The magnesium-manganese alloy AM50A with the high-temperature oxide layer on the surface in step (1) is directly exposed to the air for surface oxidation,...

Embodiment 3

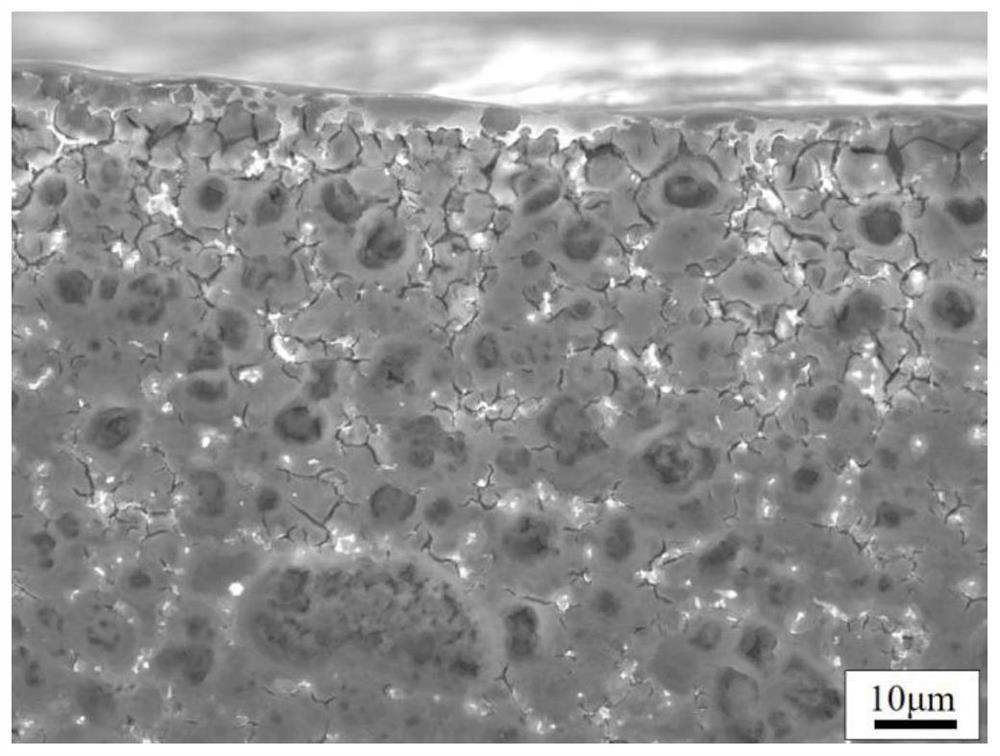

[0039] A kind of AM50A die-casting magnesium alloy with excellent corrosion resistance oxide film, its preparation method is as follows:

[0040] (1) adopt the method for automatic spraying mold release agent, with mold release agent (according to percentage by weight, it is made up of silicone oil 12%, base oil (simethicone) 8%, synthetic / wax (paraffin) 5%, additive ( Fatty alcohol polyoxyethylene ether) 3%, the rest is ultrapure water) on the die-casting mold of magnesium-manganese alloy AM50A to carry out uniform dispersion spraying (the relevant parameters in the spraying process are: spraying time 3s, spraying distance is 150mm, mold after spraying The temperature is controlled at 200°C), and a high-temperature oxide layer with a thickness of 2.2 μm is formed on the manganese-magnesium alloy AM50A;

[0041] (2) The magnesium-manganese alloy AM50A with the high-temperature oxide layer on the surface in step (1) is directly exposed to the air for surface oxidation, and an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com