Preparation method and application of 3D printing monolithic catalyst applied to Fenton-like/persulfate system

A monolithic catalyst, 3D printing technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of reducing metal ions Problems such as activation performance, difficulty in recycling metal ions, and increased demand for metal ions, etc., to achieve the effects of easy recycling and reuse, high structural controllability, and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

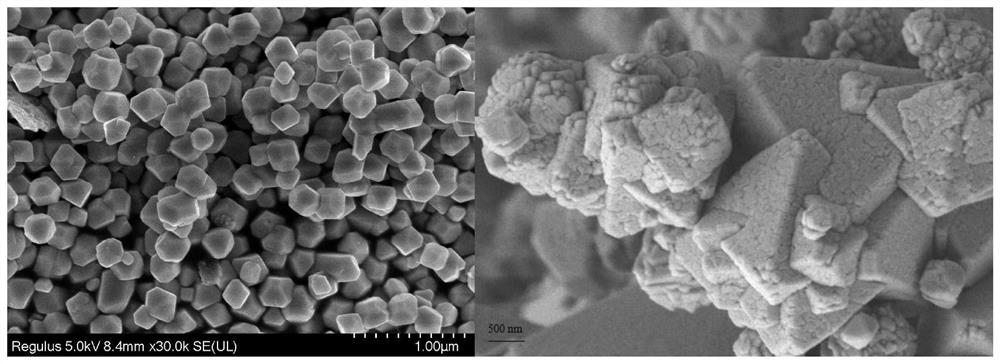

[0034] (1) Put 0.1g of anhydrous copper acetate into 50mL of pure water to obtain a transparent and clear solution. Drop into 8.0mL0.15mol / L N 2 h 4 ·H 2 O solution and stirred. Then the precipitate was separated by centrifugation, washed several times with pure water and absolute ethanol, and dried in an oven for several hours to obtain metal nanomaterials.

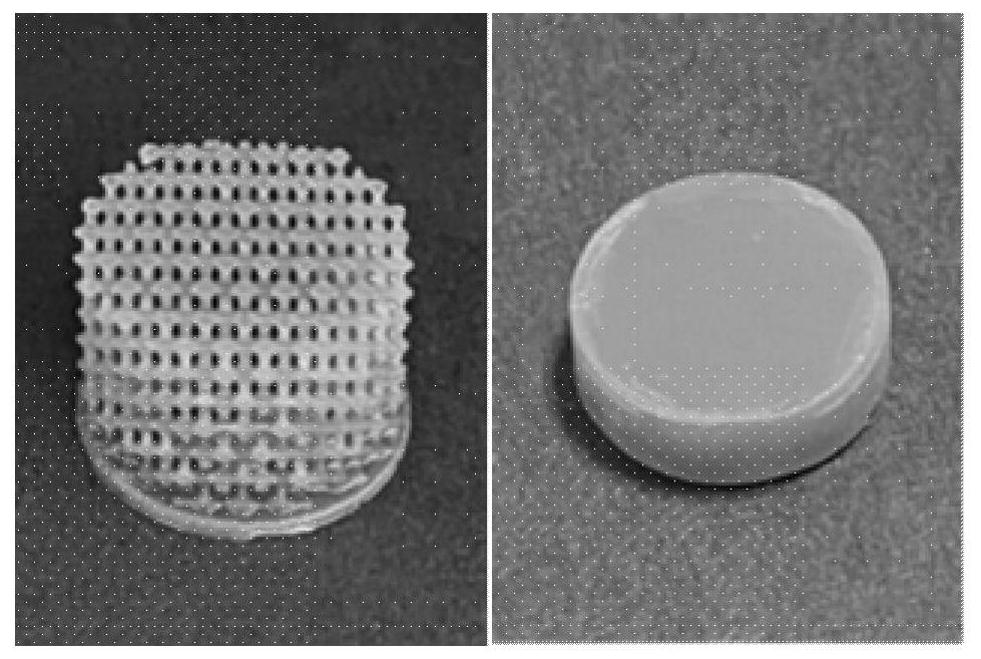

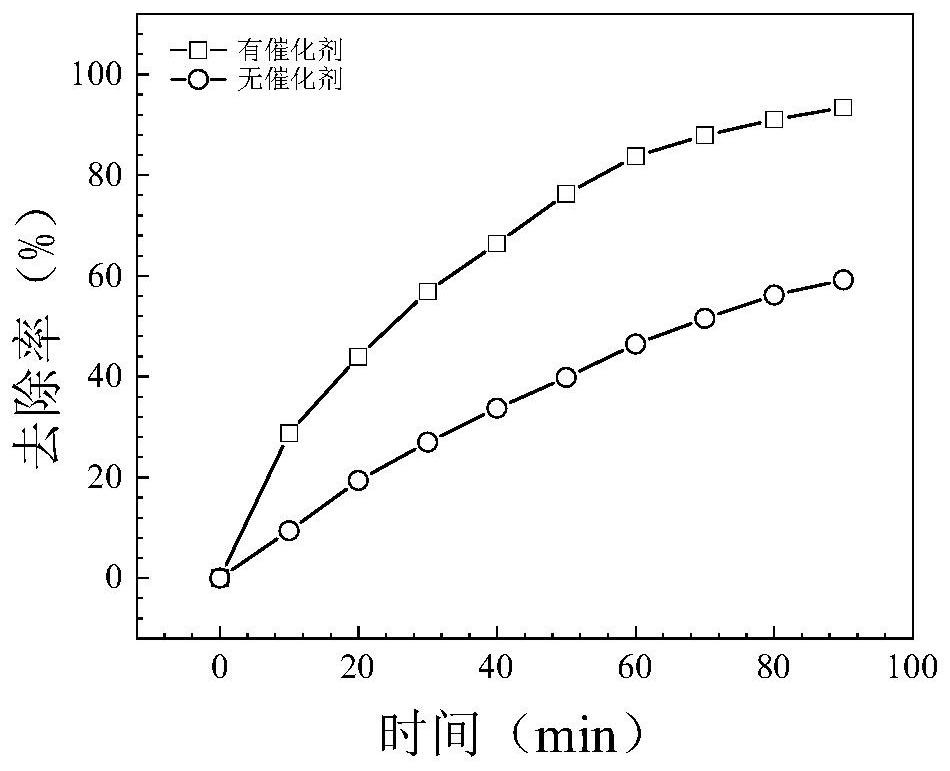

[0035] (2) 80wt% of UV curable resin, 18wt% of polyoxyethylene ether and 2wt% of metal nanomaterials were mixed and uniformly stirred, and the loading amount of metal nanomaterials was controlled to be 0.2%. Pour the mixture into the resin tank of the SLA 3D printer, and load the STL file of the ordered mesh porous cylinder structure into the slicing software, and print according to the set model. Immediately clean the uncured resin on the surface of the finished printed matter with ethanol and pure water, and after drying naturally, use N 2 As a protective gas, after calcination at 200 °C for 2 h, in N 2 Cooled to r...

Embodiment 2

[0038] (1) Put 0.1g of anhydrous ferric chloride into 50mL of pure water to obtain a transparent and clear solution. Add 8.0 mL of 0.15 mol / L sodium borohydride solution dropwise and stir. Then the precipitate was separated by centrifugation, washed several times with pure water and absolute ethanol, and dried in an oven for several hours to obtain metal nanomaterials.

[0039] (2) 80wt% of UV curable resin, 18wt% of isopropanol and 2wt% of metal nanomaterials were mixed and uniformly stirred, and the loading amount of metal nanomaterials was controlled to be 0.2%. Pour the mixture into the resin tank of the SLA 3D printer, and load the STL file of the ordered mesh porous cylinder structure into the slicing software, and print according to the set model. Immediately clean the uncured resin on the surface of the finished printed matter with ethanol and pure water, and after drying naturally, use N 2 As a protective gas, after calcination at 200 °C for 2 h, in N 2 Cooled to r...

Embodiment 3

[0042] (1) Put 0.1 g of anhydrous cobalt chloride into 40 mL of pure water to obtain a transparent and clear solution. Add 8.0 mL of 0.1 mol / L sodium citrate solution dropwise and stir. Then the precipitate was separated by centrifugation, washed several times with pure water and absolute ethanol, and dried in an oven for several hours to obtain metal nanomaterials.

[0043] (2) 80wt% of UV curable resin, 18wt% of isopropanol and 2wt% of metal nanomaterials were mixed and uniformly stirred, and the loading amount of metal nanomaterials was controlled to be 0.2%. Pour the mixture into the resin tank of the SLA 3D printer, and load the STL file of the ordered mesh porous cylinder structure into the slicing software, and print according to the set model. Immediately clean the uncured resin on the surface of the finished printed matter with ethanol and pure water, and after drying naturally, use N 2 As a protective gas, after calcination at 200 °C for 2 h, in N 2 Cooled to room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com