Preparation method of beaded carbon nanofiber-loaded titanium oxide photocatalyst

A technology of carbon nanofibers and photocatalysts, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy shedding, uneven distribution, etc., and achieve sufficient exposure, large specific surface area, and circulation good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

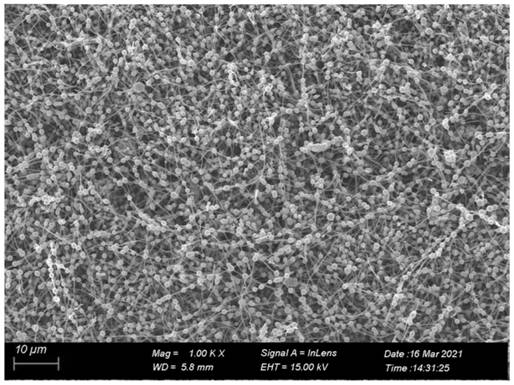

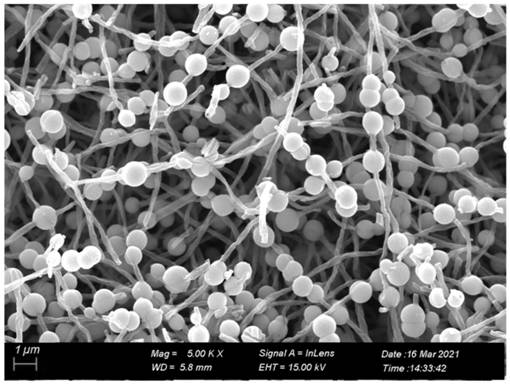

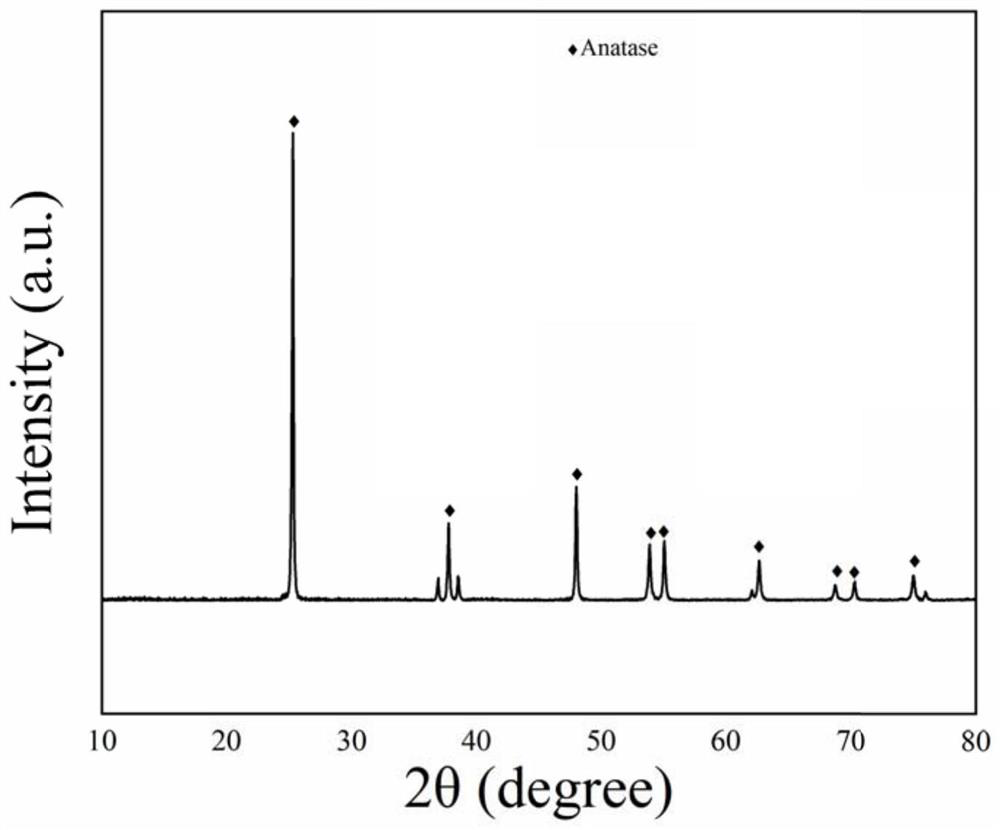

[0050] The preparation method of the beaded, carbon nanofiber-loaded, nitrogen-fluorine co-doped oxygen-deficient titanium oxide photocatalyst that the present invention proposes comprises the following steps and contents:

[0051] (1) First, dissolve 1-2.5g of analytically pure polyacrylonitrile powder with a molecular weight of 100,000-150,000 in 15mL of N,N-dimethylformamide, and magnetically stir for 10-12h at 50-60°C under heat preservation conditions. Obtain a transparent solution that is fully dissolved and uniformly dispersed;

[0052] (2) Then the solution obtained in step (1) is placed in a syringe, and a polyacrylonitrile fiber membrane is prepared by electrospinning, and it is set aside;

[0053] (3) Then mix 1.5-9.6g of analytically pure tetrabutyl titanate, 0.02-0.15g of analytically pure ammonium fluoride, and 3-5mL of analytically pure glacial acetic acid in 40-80mL of absolute ethanol, and stir magnetically at room temperature for 20- 40min to obtain a homoge...

Embodiment

[0062] Example: 1.5 g of analytically pure polyacrylonitrile powder with a molecular weight of 150,000 was dissolved in 15 mL of N,N-dimethylformamide, and magnetically stirred at 60° C. for 10 h to obtain a transparent solution. Then use a 10mL syringe to draw 10mL of the above solution, install a No. 22 flat metal needle, set the spinning parameters as follows: the spinning voltage is 16kV, the spinning temperature is 30°C, and the humidity is 50%. The spacing is 15 cm, the rotational speed of the receiving roller is 60 rpm, and the flow rate of the solution is 0.0015 mm / s; spin to obtain a white polyacrylonitrile fiber membrane for use. Then, add 60mL of absolute ethanol, 4mL of glacial acetic acid, 5.8g of tetrabutyl titanate and 0.1g of ammonium fluoride into a 100mL beaker, stir magnetically at room temperature for 40min and mix well; then transfer to a hydrothermal reaction kettle with a capacity of 100mL, Add about 0.25g of the prepared polyacrylonitrile fiber membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com