Preparation method and application of H2O2-modified TiO2/mesoporous glass catalyst

A mesoporous glass, H2O2 technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of reduced specific surface area, small particle size, small reaction contact area, etc., to improve reaction contact Area and light absorption capacity, reducing post-processing steps, and solving the effect of low mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

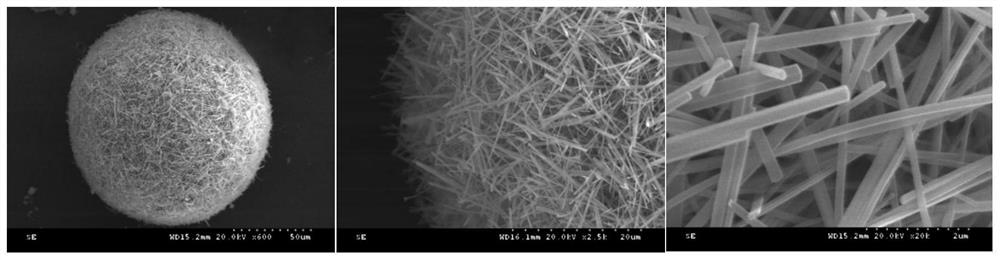

[0040] Put 5 g of glass microspheres and 200 mL of deionized water in a high-temperature and high-pressure reactor, raise the pressure of the reactor to 12.5 MPa, and the temperature is 325 ° C, and keep it in the subcritical state for 2 hours. After the temperature of the reactor drops to room temperature, pass The etched glass microspheres were separated from water by filtration, washed several times with deionized water until pH = 7, and then dried for use.

[0041] Add 0.15mL tetrabutyl titanate to a mixed solution of 13mL hydrogen peroxide and 20mL isopropanol to obtain a yellow transparent solution, then add 0.03g hexadecyl ammonium bromide and 0.65g mesoporous glass carrier, ultrasonically disperse evenly Then add 5 mL of deionized water and 10 mL of isopropanol dropwise into a mixed solution, heat to 50°C for hydrolysis for 1 h, transfer the resulting mixture to a stainless steel autoclave, and conduct a crystallization reaction at 140°C for 4 h. The product is centrifu...

Embodiment 2

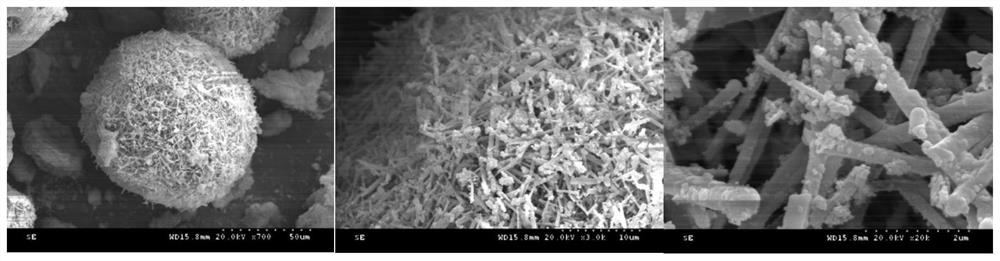

[0043] Prepare H according to the method of Example 1 2 o 2 Modified TiO 2 / Mesoporous glass photocatalytic oxidation-adsorption desulfurization catalyst, the difference is that the addition of tetrabutyl titanate is 0.31mL, and the titanium dioxide loading of the obtained catalyst is 10wt%.

Embodiment 3

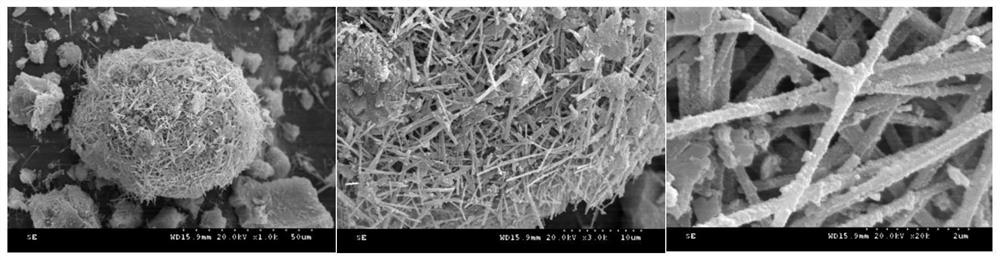

[0045] Prepare H according to the method of Example 1 2 o 2 Modified TiO 2 / Mesoporous glass photocatalytic oxidation-adsorption desulfurization catalyst, the difference is that the addition of tetrabutyl titanate is 0.49mL, and the titanium dioxide loading of the obtained catalyst is 15wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com