A kind of nano-reinforced environment-friendly organic silicon antifouling and antibacterial coating and its preparation method and application

A nano-reinforced, antibacterial coating technology, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of limited source of antifouling agent raw materials, backward extraction technology, poor water solubility, etc. Achieve excellent antifouling and antibacterial performance, improve antibacterial and antifouling performance, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

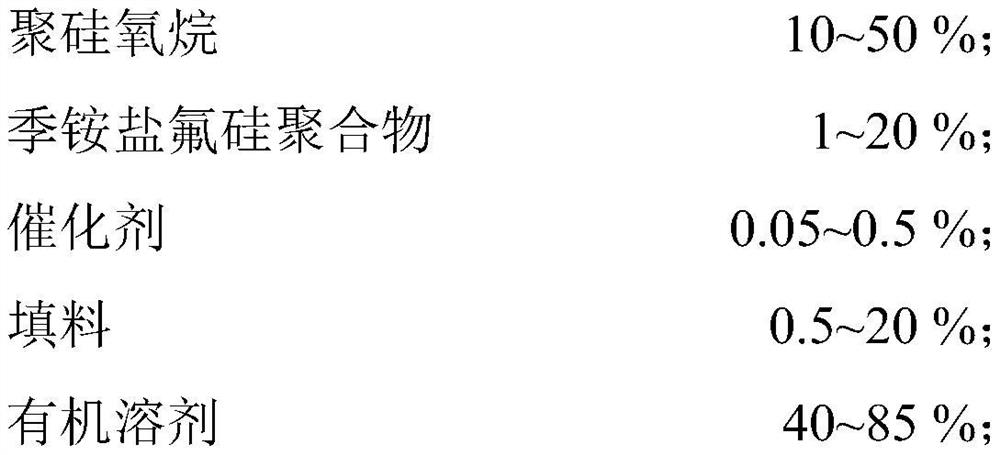

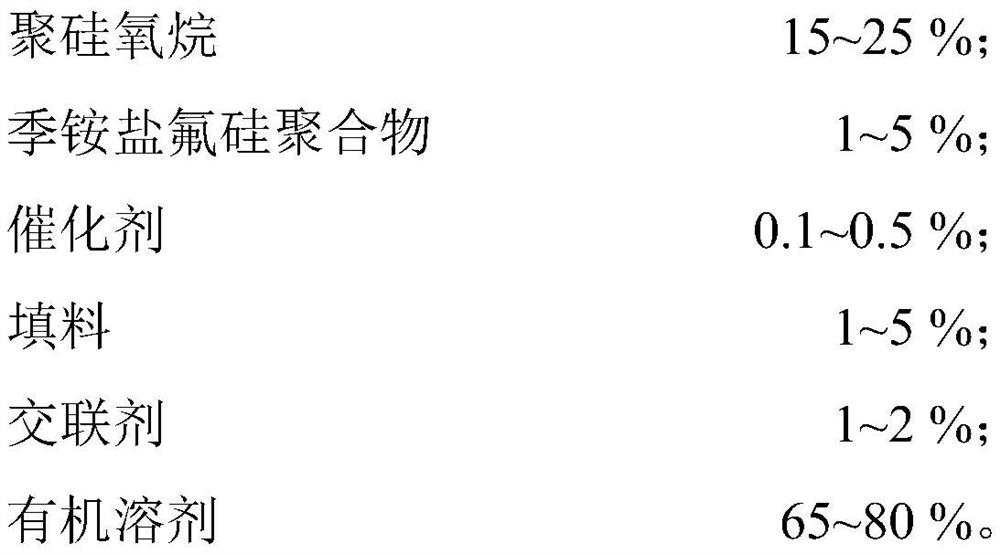

Method used

Image

Examples

Embodiment 1

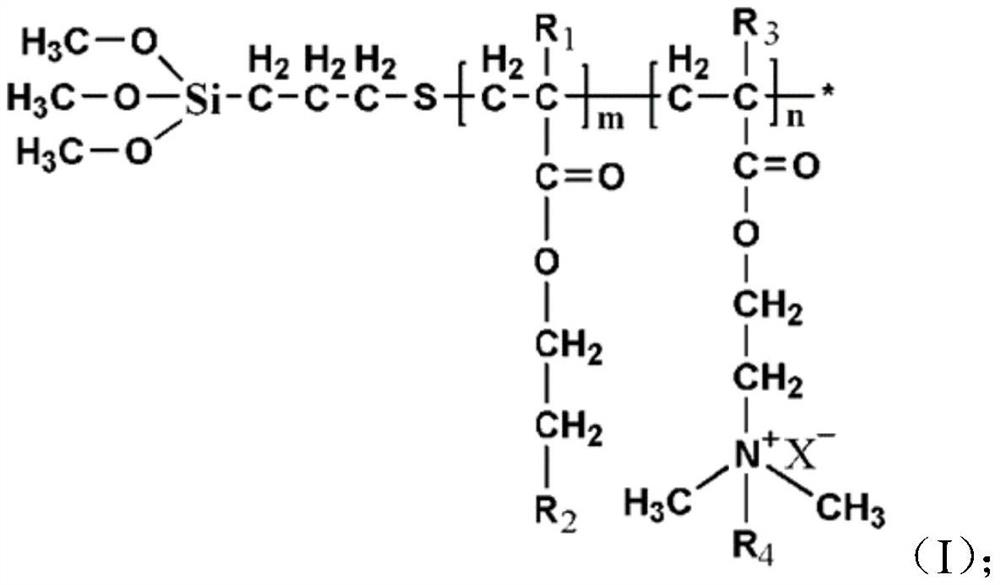

[0063] (1) 0.78g (0.004mol) 3-mercaptopropyltrimethoxysilane, 2.03g (0.0072mol) methacryloxyethyl benzyl dimethyl ammonium chloride, 4.18g (0.01mol) 2- Ethyl perfluorohexyl acrylate and 20g of acetonitrile were added to the container, nitrogen gas was passed through for 15min to remove the air in the reaction flask, 0.1g of initiator azobisisobutyronitrile was added, and the reaction was carried out at 80°C for 12h under a nitrogen atmosphere. Precipitate in alkanes, dry under vacuum to obtain quaternary ammonium fluorosilicon polymer, the molecular weight is 3200g / mol, and the structural formula conforms to formula (I), where, R 1 for H, R 2 for C 6 f 13 , R 3 for CH 3 , R 4 for C 6 h 5 CH 2 , X is Cl.

[0064] (2) 0.35g of the quaternary ammonium salt fluorosilicon polymer prepared in step (1), 2.8g of polydimethylsiloxane with a dynamic viscosity of 40000mPa·s hydroxyl-terminated, 0.5g of nano-titanium dioxide, and 0.15g of tetraorthosilicate Ethyl ester, 0.04g of...

Embodiment 2

[0066] The preparation process is basically the same as that in Example 1, except that in step (2), 0.5 g of nano-titanium dioxide is replaced by 0.5 g of nano-zinc oxide.

Embodiment 3

[0068] The preparation process is basically the same as that in Example 1, except that in step (2), 0.5 g of nanometer titanium dioxide is replaced by 0.5 g of nanometer silicon dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com