Tetracycline purification fiber membrane and preparation method thereof

A tetracycline, fiber membrane technology, applied in the field of water treatment, can solve the problems of affecting stability, poor ductility, poor thermal stability and chemical durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

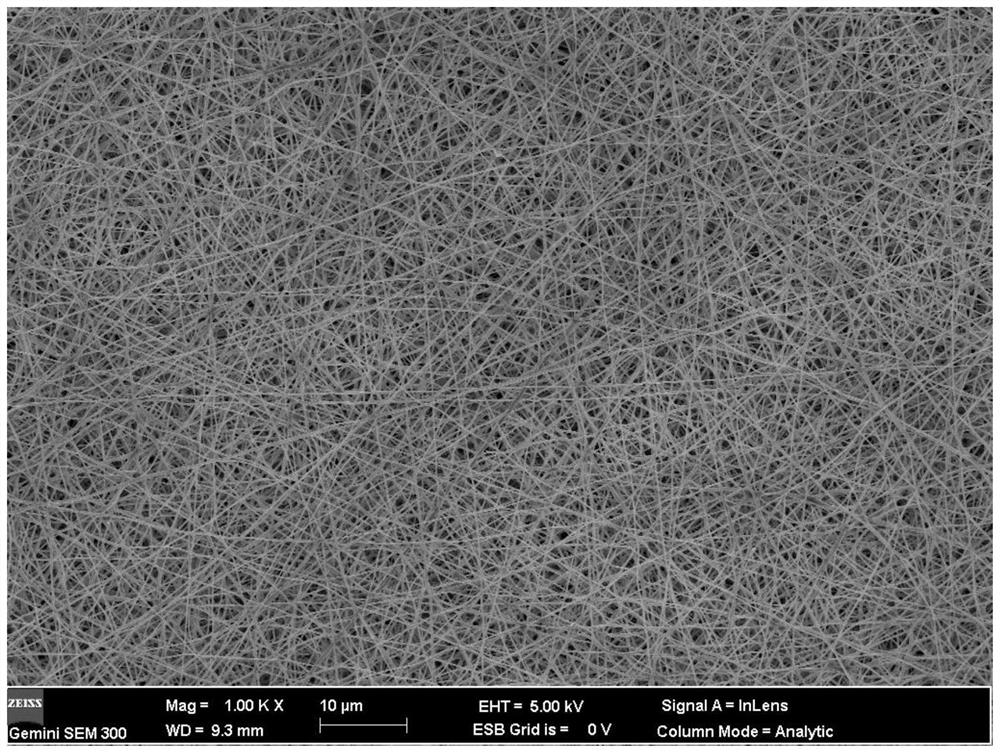

Image

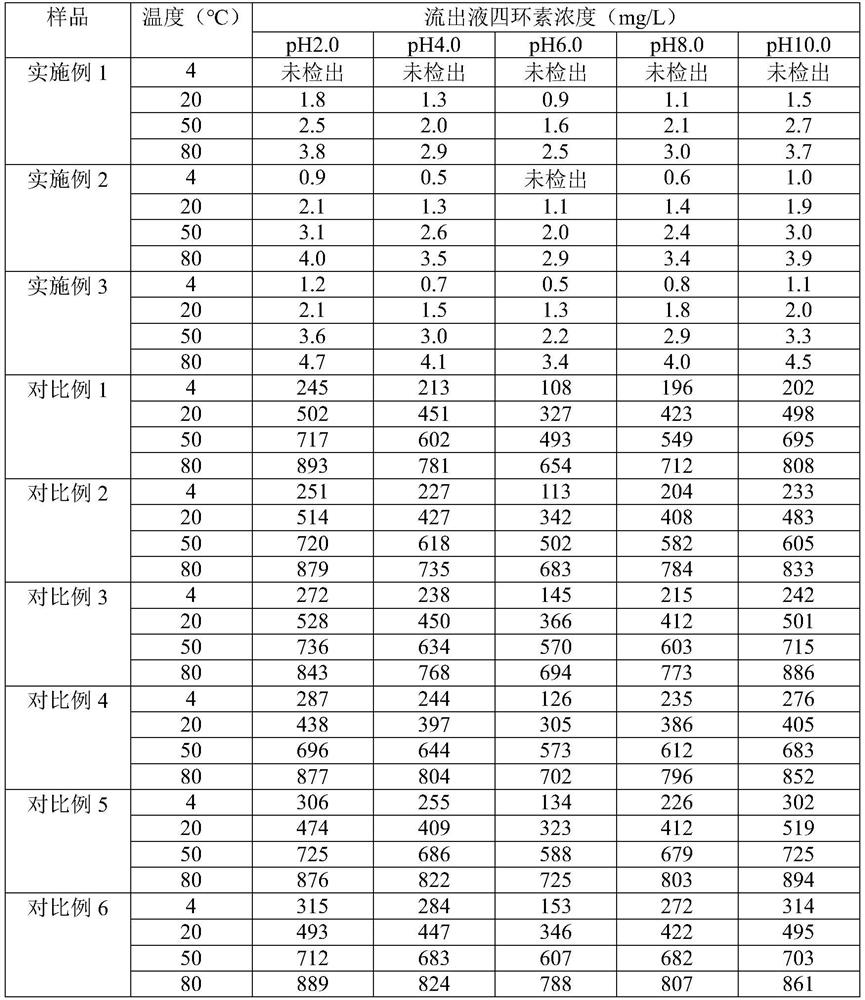

Examples

Embodiment 1

[0023] A tetracycline purification fiber membrane and a preparation method thereof, comprising the steps of:

[0024] 1. Mix 2.45g of chromium triboride, 1.05g of gallium phosphide and 5.25g of erbium(III) perchlorate hexahydrate and put it into a vacuum resistance furnace at 2200°C for 20 hours of heating reaction. The product is soaked in 100mL with a concentration of 19g / L The phloroglucinol ethanol solution was added into a planetary grinder, mixed and ground to obtain particles with an average particle size of 150 nm, and vacuum-dried to obtain a photocatalytic oxidant.

[0025] 2. Add 7g of the photocatalyst oxidant prepared in step 1, 0.8g of dispersant BYK-9076, 0.3g of foaming agent MIBC, and 24g of polymethyl methacrylate into 100mL of acetone and a mixed solvent of DMF with a volume ratio of 1:1 As the shell spinning solution and thermoplastic polyurethane elastomer melt as the core spinning solution, the spinning voltage is 20kV, the shell spinning solution tempera...

Embodiment 2

[0027] A tetracycline purification fiber membrane and a preparation method thereof, comprising the steps of:

[0028] 1. Mix 1.46g of chromium triboride, 1.21g of gallium phosphide and 3.44g of erbium(III) perchlorate hexahydrate and put it into a vacuum resistance furnace at 2000°C for 24h heating reaction. The product is soaked in 100mL with a concentration of 18g / L The phloroglucinol ethanol solution was added into a planetary grinder, mixed and ground to obtain particles with an average particle size of 100 nm, and dried in vacuum to obtain a photocatalytic oxidant.

[0029] 2. Add 5g of the photocatalytic oxidant prepared in step 1, 0.5g of dispersant BYK-W961, 0.2g of foaming agent BK201, and 20g of polymethyl methacrylate into 100mL of acetone and DMF in a mixed solvent with a volume ratio of 1:1 As the shell spinning solution and thermoplastic polyurethane elastomer melt as the core spinning solution, the spinning voltage is 18kV, the temperature of the shell spinning ...

Embodiment 3

[0031] A tetracycline purification fiber membrane and a preparation method thereof, comprising the steps of:

[0032] 1. Mix 4.39g of chromium triboride, 0.81g of gallium phosphide and 8.03g of erbium(III) perchlorate hexahydrate and put it in a vacuum resistance furnace at 2400°C for 18 hours of heating reaction. The product is soaked in 100mL with a concentration of 20g / L The phloroglucinol ethanol solution was added into a planetary grinder, mixed and ground to obtain particles with an average particle size of 200nm, and vacuum-dried to obtain a photocatalytic oxidant.

[0033] 2. Add 9g of the photocatalytic oxidant prepared in step 1, 1g of dispersant BYK-W969, 0.4g of foaming agent BK204, and 26g of polymethyl methacrylate into 100mL of acetone and a mixed solvent with a volume ratio of DMF of 1:1 as The shell spinning solution and thermoplastic polyurethane elastomer melt are used as the core spinning solution. At a spinning voltage of 22kV, the temperature of the shell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com