Recombinant rhamnolipid-producing strain and application thereof

A technology for producing rhamnolipids and bacteria, which is applied in the fields of applied microorganisms and genetic engineering, and can solve the problems of limiting the large-scale application of rhamnolipids, high fermentation costs, and low yields of rhamnolipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

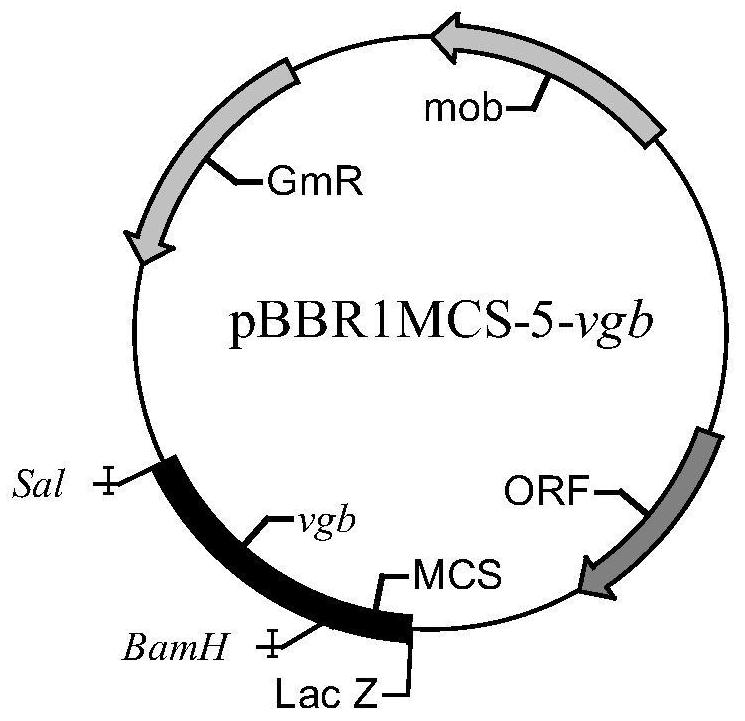

[0023] Example 1: Construction of the plasmid pBBR1MCS-5-vgb expressing hemoglobin

[0024] Using primers vgb-f: CGCGGATCCGGAAGACCCTCATGTTAGA, vgb-r: ATTATCTAGATTATTCAACCGCTTGAGCGTA, the complete vgb gene fragment was obtained by PCR from Hyacinthus faecalis (ATCC 15218), and the fragment was ligated into the cloning vector pMD19-T to obtain the recombinant vector pMD19- T-vgb.

[0025] Use BamHI and SalI to double digest the plasmids pBBR1MCS-5 and pMD19-T-vgb. After digestion, use the kit to recover the large fragment after pBBR1MCS-5 digestion. pMD19-T-vgb cut the gel to recover the vgb fragment, and recover the two fragments Ligated by T4 ligase, the recombinant plasmid pBBR1MCS-5-vgb was obtained (see figure 1 ).

Embodiment 2

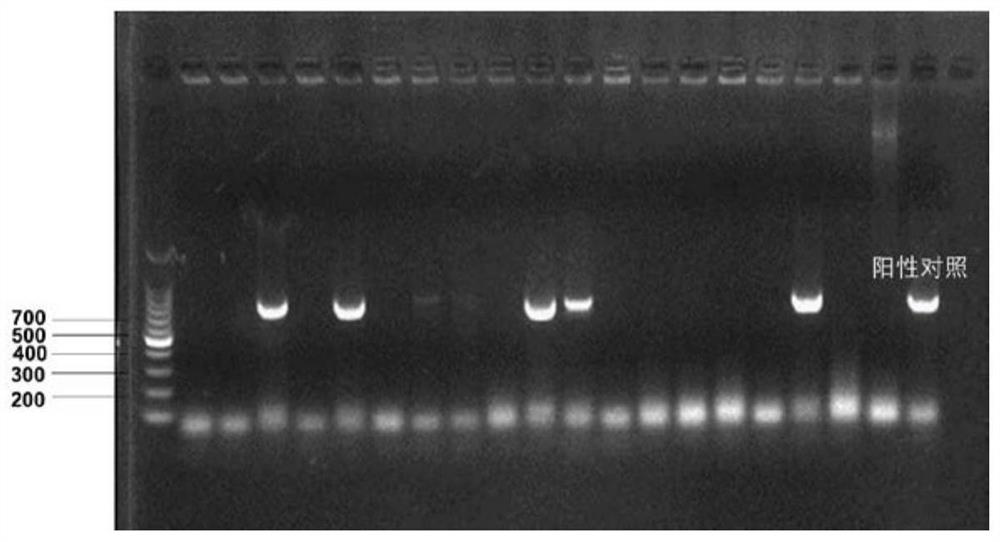

[0026] Embodiment 2: Construction of Pseudomonas aeruginosa engineered bacteria expressing hemoglobin

[0027] The recombinant plasmid pBBR1MCS-5-vgb in Example 1 was transformed into competent Pseudomonas aeruginosa by calcium chloride heat shock method, coated with LB solid plate containing 50 μg / mL gentamicin, and cultured at a constant temperature of 37°C until growth The transformants were verified by PCR to obtain Pseudomonas aeruginosa engineering bacteria expressing VHb. The specific method is as follows:

[0028] (1) Pseudomonas aeruginosa was inoculated into 5 mL of LB liquid medium for activation culture, and the culture conditions were 37° C., 180 rpm. (2) Dip the inoculated loop to pick up the activated bacterial solution, streak it on the LB plate, and incubate overnight at 37°C. (3) Pick out a single colony and inoculate it into LB liquid medium, and culture it at 37°C and 180rpm. (4) Transfer the culture solution obtained above to fresh LB liquid medium at a...

Embodiment 3

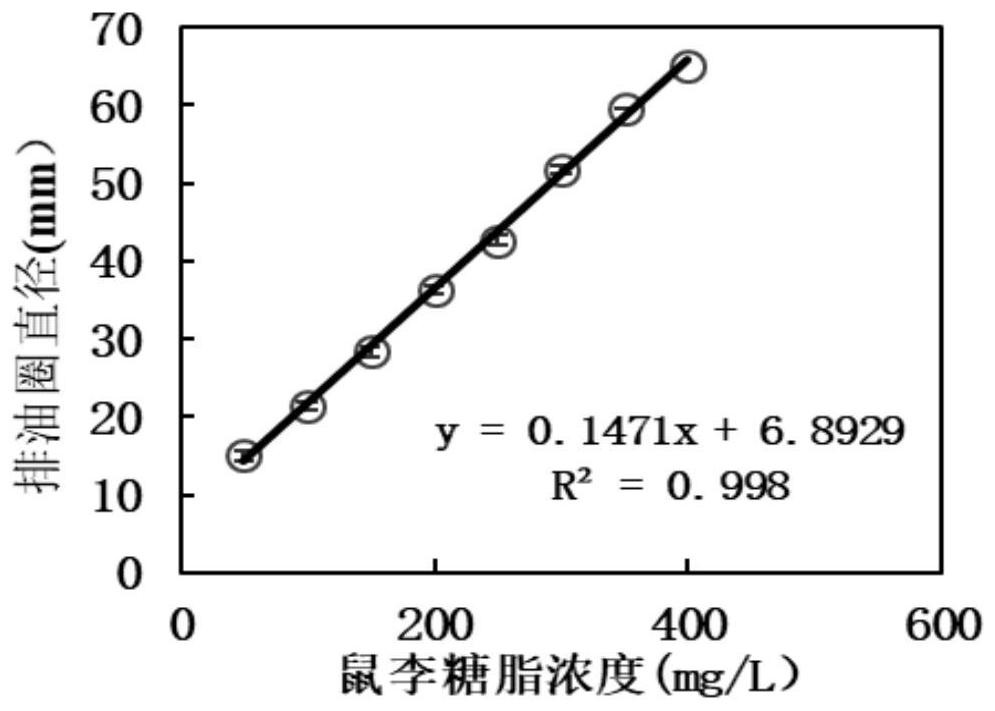

[0029] Example 3: Application of expressing hemoglobin in improving rhamnolipid production

[0030] Inoculate wild-type Pseudomonas aeruginosa and the hemoglobin-expressing bacterial strain obtained in Example 2 into 250mL Erlenmeyer flasks containing 100mL seed medium respectively, and the culture conditions are 37°C, 180rpm; each culture experiment is three parallel repeated experiments . The next day, the seed solution was inoculated into 250mL containing 150mL fermentation medium with an inoculation amount of 3wt%, cultivated for 7 days at 37°C, and the shaker speed was 180rpm. The experiment was three parallel experiments. Type Pseudomonas aeruginosa and engineering bacteria rhamnolipid production.

[0031] The fermentation medium is calculated by weight percentage, and the above seed medium is: 1.2% yeast powder, 2.4% peptone, 1% sodium chloride, and the balance is water; the fermentation medium is 2.5% glycerol, 1% soybean oil , nitrate 0.35%, phosphate 1.7%, sodium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com