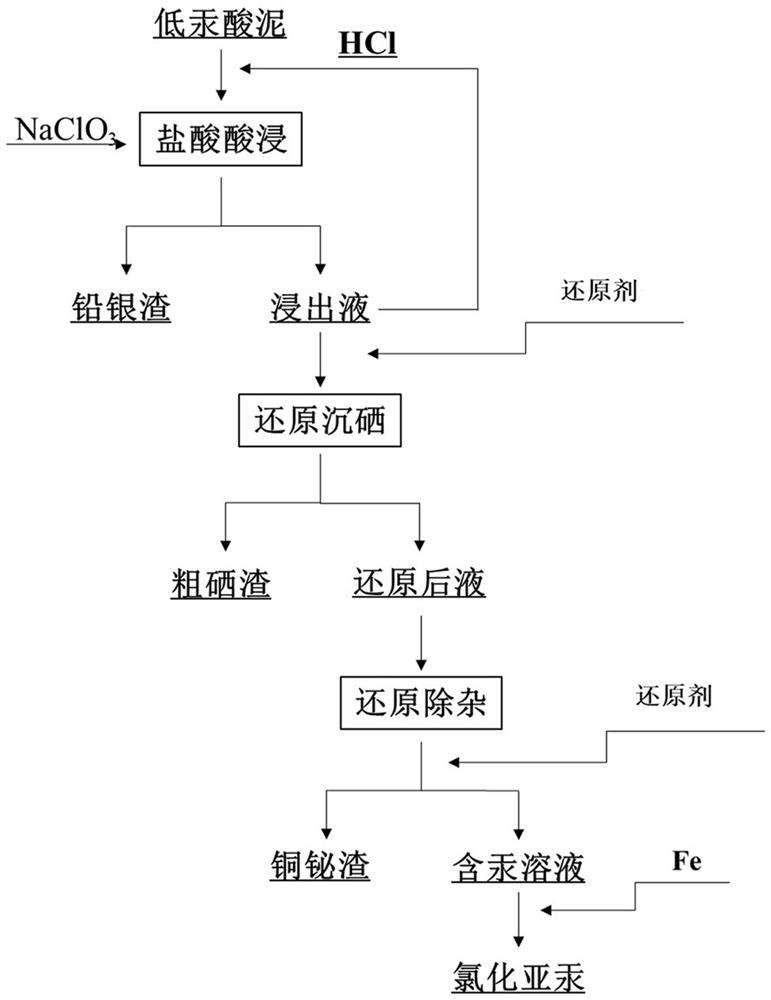

Method for recovering mercury from nonferrous metallurgy low-mercury acid mud by adopting wet process technology

A technology of acid mud and technology, applied in the field of resource technology application, can solve the problems of secondary pollution, mercury vapor entering the atmosphere, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The mercury element content in acid mud is 0.96%.

[0045]Take 50g of low-mercuric acid mud, and after drying, weigh 41.395g of dried acid mud, grind it to a particle size of about 200 mesh, and place the acid mud particles evenly in a beaker. Configure concentrated hydrochloric acid, take 320ml of analytically pure concentrated hydrochloric acid with a concentration of 36% and place it in a 1000ml volumetric flask, take 500ml of UP water and add it to the volumetric flask to dilute the concentrated hydrochloric acid. Configure 1mol / L sodium hydroxide solution to titrate the concentration of concentrated hydrochloric acid. After titration, the concentration of concentrated hydrochloric acid was 127g / L. Add 85ml of concentrated hydrochloric acid into the beaker according to the mass ratio of acid mud to concentrated hydrochloric acid volume ratio of about 1:1.7. According to the dosage of sodium chlorate is twice the mercury content in the acid mud, weigh 8g of sodium ...

Embodiment 2

[0050] The mercury content in acid mud is 0.79%.

[0051] Take 50g of low-mercuric acid mud, after drying, weigh 40.84g of acid mud with a dry weight, grind it to a particle size of about 200 mesh, and place the fine particles of acid mud evenly in a beaker. Adopt the concentrated hydrochloric acid of embodiment 1 same concentration. Add 85ml of concentrated hydrochloric acid to the beaker according to the volume ratio of acid mud to concentrated hydrochloric acid 1:1.7, and add 4g of sodium chlorate to the beaker according to the dosage of sodium chlorate is 4 times the mercury content in the acid mud. The reaction was stirred at a room temperature of 25° C. at a rotational speed of 350 r / min. React for six hours, after complete reaction, let stand to settle. After centrifugation and filtration, the mass of lead and silver slag obtained by filtration was 50.2240g. After drying, the quality of dry lead and silver slag was 40.3801g, and the moisture content was 19.6%. The per...

Embodiment 3

[0056] The Hg content in low mercury acid mud is about 0.5%.

[0057] Acid leaching with sodium chlorate hydrochloride system: firstly dry and grind the low mercury acid mud to a particle size of 150 mesh, add hydrochloric acid with a concentration of 120g / L to the low mercury acid mud, add low mercury acid mud and hydrochloric acid The ratio of the amount is 1(g): 1.7(ml). After adding hydrochloric acid, add sodium chlorate, wherein the amount of sodium chlorate added is twice the mercury content in the acid mud; after adding all the medicines, stir Make the reaction fully, the stirring speed is 300r / min, the reaction time is 4 hours, filter to obtain lead and silver slag and leaching solution; repeat step S1 once to increase the concentration of mercury in the leaching solution.

[0058] Reduction of selenium precipitation: Slowly add a reducing agent to the obtained leaching solution, and the dosage ratio is 1.2:1 (mass ratio) of reducing agent: selenium. The reducing agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com