Novel anti-crack fiber and composite material preparation method

A technology of anti-cracking fiber and composite materials, which is applied in the field of anti-cracking fiber, can solve the problems of low hardness and toughness, shorten the service life of anti-cracking fiber, and insufficient corrosion resistance, so as to reduce the difficulty of composite processing, improve corrosion resistance, Effect of improving hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

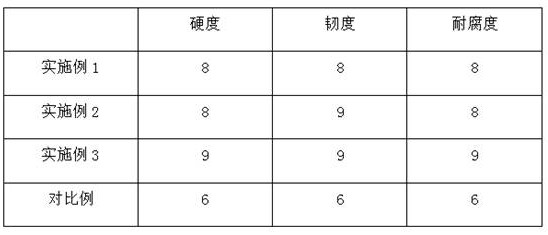

Examples

Embodiment 1

[0023] New cracking fiber formulation comprising: polypropylene, diethyl maleate, styrene, dicumyl peroxide, a polyurethane resin, a reinforcing agent, a silicone defoamer and a colorant, parts by weight of the components are numbers: 82 to 94 parts polypropylene, 17 to 23 parts of diethyl maleate, 6 to 10 parts of styrene, 2 to 4 parts of dicumyl peroxide, 9 to 13 parts of a polyurethane resin, 3-7 parts of a reinforcing agent, 1-3 parts of a silicone antifoam and from 1 to 3 parts of a colorant, a reinforcing agent, asbestos powder, mica, talc and quartz sand are mixed, and asbestos powder, the weight ratio of mica, talc and quartz sand as 5:1:3:2, colorants chosen iron oxide black, titanium dioxide, chrome vermilion, chrome yellow, cobalt blue and either or both.

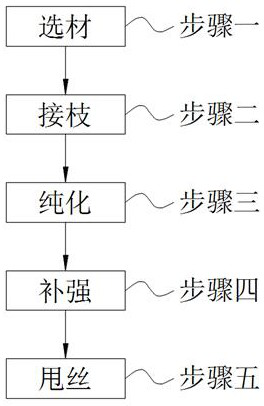

[0024] The method of preparing novel cracking fiber composite material, comprising the steps of: a step, selection; step two, the graft; three step purification; Step four, the reinforcing; Step five, spun;

[0025] ...

Embodiment 2

[0031] New cracking fiber formulation comprising: polypropylene, diethyl maleate, styrene, dicumyl peroxide, a polyurethane resin, a reinforcing agent, a silicone defoamer and a colorant, parts by weight of the components are numbers: 82 to 94 parts polypropylene, 17 to 23 parts of diethyl maleate, 6 to 10 parts of styrene, 2 to 4 parts of dicumyl peroxide, 9 to 13 parts of a polyurethane resin, 3-7 parts of a reinforcing agent, 1-3 parts of a silicone antifoam and from 1 to 3 parts of a colorant, a reinforcing agent, asbestos powder, mica, talc and quartz sand are mixed, and asbestos powder, the weight ratio of mica, talc and quartz sand as 5:1:3:2, colorants chosen iron oxide black, titanium dioxide, chrome vermilion, chrome yellow, cobalt blue and either or both.

[0032] The method of preparing novel cracking fiber composite material, comprising the steps of: a step, selection; step two, the graft; three step purification; Step four, the reinforcing; Step five, spun;

[0033] ...

Embodiment 3

[0039] New anti-crack fibers, formulations include: polypropylene, diethyl maleate, styrene, peroxidated diisopropyl, polyurethane resin, reinforcing agent, silicone defoamper, and colorant, weight parts of each component The numbers are: 82 to 94 parts of polypropylene, 17 to 23 parts of diethyl maleate, 6 to 10 parts of styrene, 2 to 4 parts of diisoppopopus, 9 to 13 parts of polyurethane Resin, 3 to 7 parts of reinforcing agent, 1 to 3 parts of the silicone defoamper and 1 to 3 parts of colorant, the reinforcing agent is mixed by asbestos powder, mica powder, talc powder and quartz sand, and The weight ratio of asbesto powder, mica powder, talc, and quartz sand is 5: 1:3: 2, and the colorants are used in arbitrary one or two of iron oxide black, titanium powder, molybdenum chromium red, chrome yellow and cobalt blue.

[0040] The preparation method of the composite material of the new anti-cracked fiber, including the following steps: step one, material; step two, graf; step th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com