Method for preparing fluoride-free MXene by adopting electrochemical etching method

An etching method and electrochemical technology, applied in the field of preparation of inorganic non-metallic materials, can solve the problems of increased equipment requirements, high hydrothermal temperature, cumbersomeness, etc., and achieve the effect of short etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

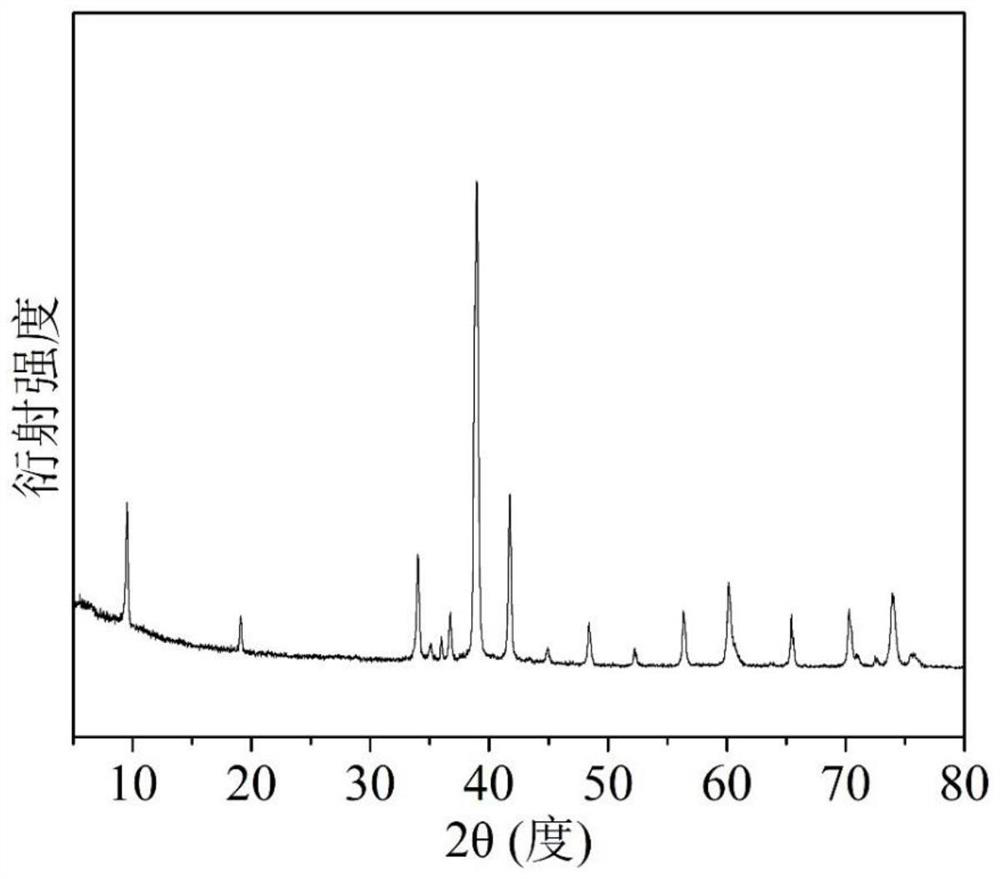

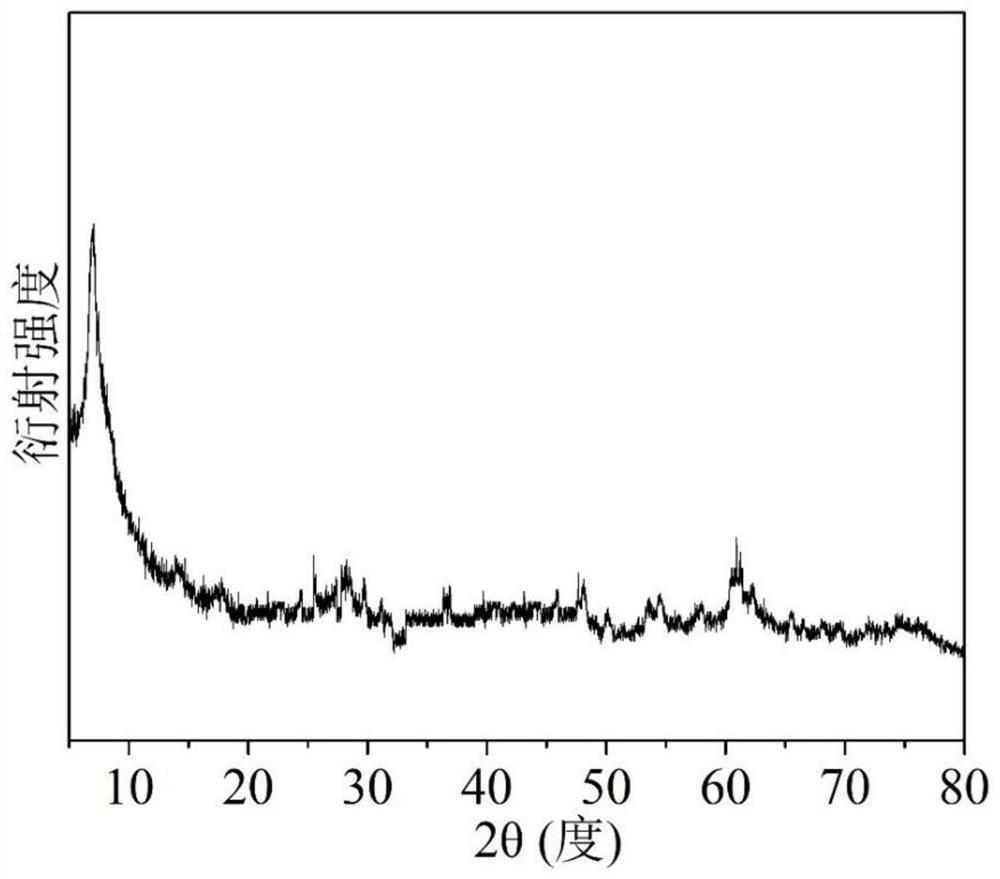

[0019] (1) put two pieces of Ti 3 AlC 2 The block (3cm×1cm×0.5cm) was used as the working electrode and the counter electrode respectively, immersed in a mixed aqueous solution of 0.8M LiOH and 1.0M LiCl, and a voltage of 5.5V was applied, and the solution was kept under stirring for 5h;

[0020] (2) Collect the black precipitate in the solution by centrifugal washing at 3500rpm, and then sonicate for 30min under ice-water bath and inert gas protection conditions;

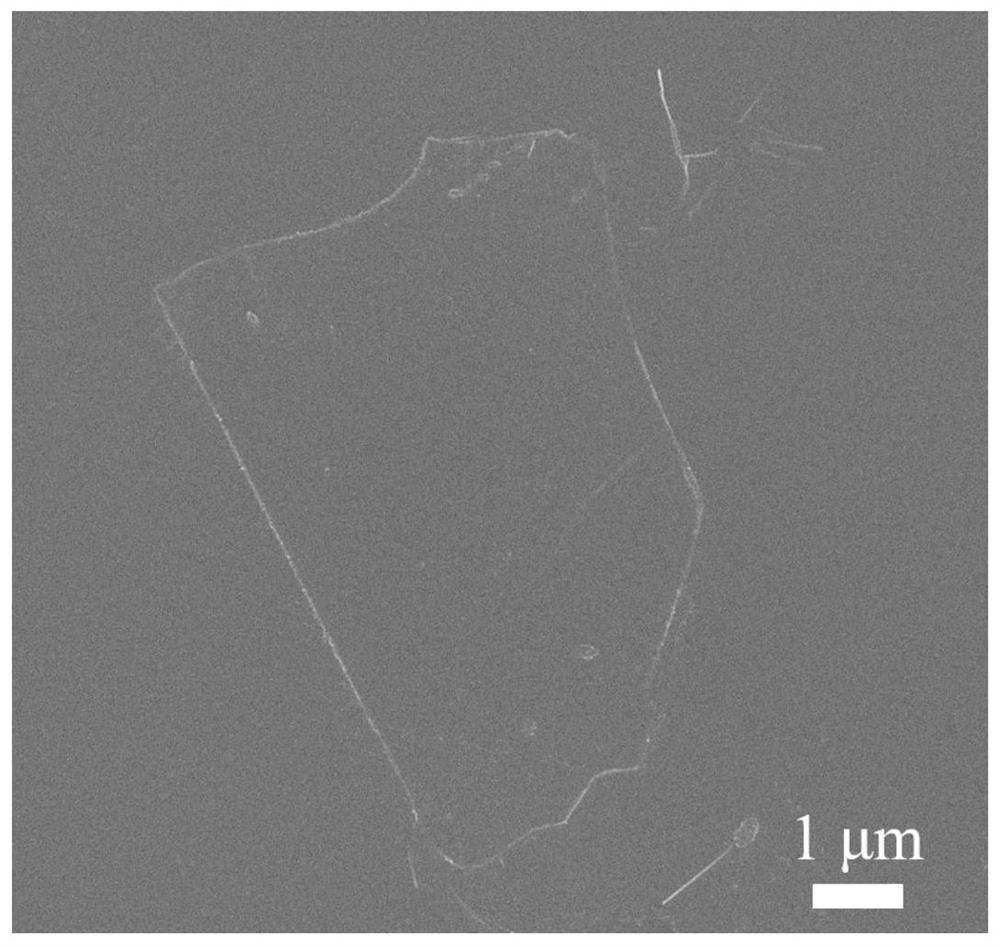

[0021] (3) Centrifugal washing at 3500 rpm for several times until the supernatant turns black, and then freeze-dry the black supernatant to obtain few-layer or single-layer MXene.

[0022] The above step (2) and step (3) can be repeated.

[0023] Assembly and testing of supercapacitors: the few-layer or single-layer MXene prepared in this example was used as the active material, mixed evenly with carbon fiber and nanocellulose at a mass ratio of 7:2:1, and then a flexible film was obtained by vacuum filtration ...

Embodiment 2

[0028] (1) put two pieces of Ti 3 AlC 2 The block (3cm×1cm×0.5cm) was used as the working electrode and the counter electrode respectively, immersed in a mixed aqueous solution of 0.2M LiOH and 1.0M LiCl, and a voltage of 5.5V was applied, and the solution was kept under stirring for 5h;

[0029] (2) Collect the black precipitate in the solution by centrifugal washing, then sonicate for 30min under ice-water bath and inert gas protection conditions;

[0030] (3) Multiple centrifugation and washing until the supernatant turns black, and then freeze-dry the black supernatant to obtain few-layer or single-layer MXene.

[0031] The above step (2) and step (3) can be repeated.

[0032] The assembly and testing of the supercapacitor refer to Example 1. At 1, 2, 4, 8 and 10mA / cm 2 The discharge specific capacitances at current densities are 92.9, 83.1, 71.4, 58.4 and 53.6 F / g, respectively.

Embodiment 3

[0034] (1) put two pieces of Ti 3 AlC 2 The block (3cm×1cm×0.5cm) was used as the working electrode and the counter electrode respectively, immersed in a mixed aqueous solution of 0.4M LiOH and 1.0M LiCl, and a voltage of 5.5V was applied, and the solution was kept under stirring for 5h;

[0035] (2) Collect the black precipitate in the solution by centrifugal washing, then sonicate for 30min under ice-water bath and inert gas protection conditions;

[0036] (3) Multiple centrifugation and washing until the supernatant turns black, and then freeze-dry the black supernatant to obtain few-layer or single-layer MXene.

[0037]The above step (2) and step (3) can be repeated.

[0038] The assembly and testing of the supercapacitor refer to Example 1. At 1, 2, 4, 8 and 10mA / cm 2 The discharge specific capacitances at current densities were 175.0, 155.6, 138.1, 115.8 and 106.6 F / g, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com