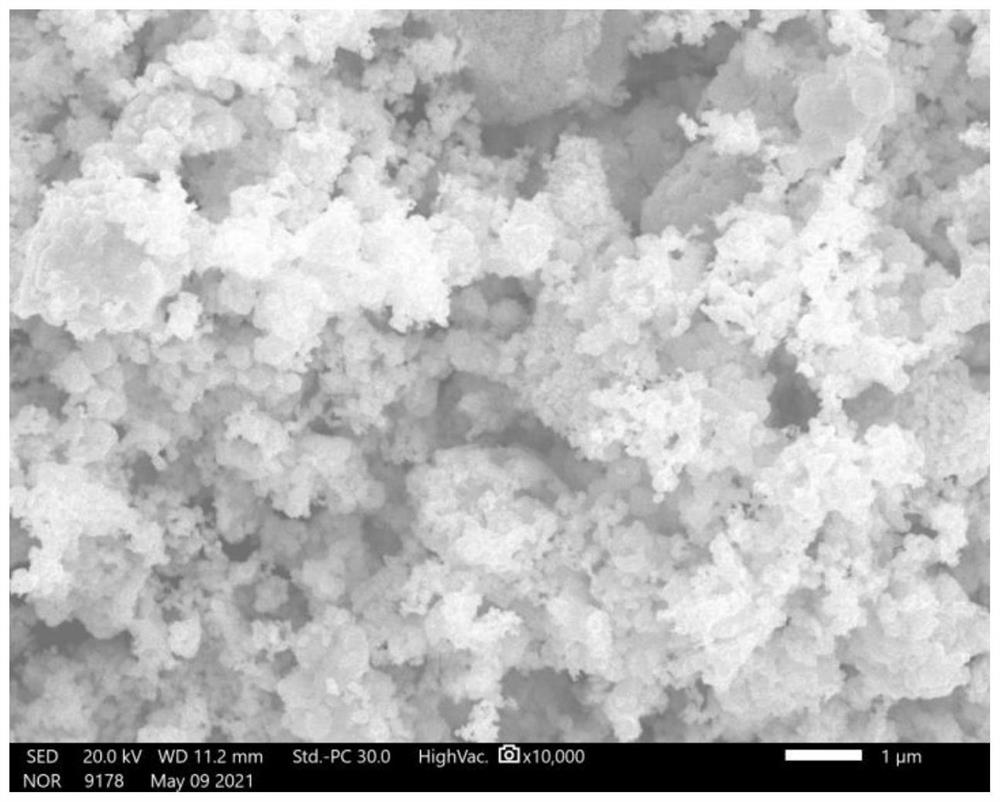

Preparation process of nano cobalt powder

A preparation process, nano-cobalt technology, applied in the direction of nanotechnology, etc., can solve the problems of fast reaction speed, low yield of cobalt powder, high oxygen content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of 1# nano cobalt powder.

[0034] (a) The cobalt raw material is a mixture of cobalt chloride and cobalt oxalate with a molar ratio of 3:1, and the cobalt raw material is dissolved in 5L of a water-alcoholic mixture of ethanol and water with a specific gravity of 0.85 to obtain a pink raw material solution. Add 25wt% ammonia water and solid sodium hydroxide to the raw material liquid to adjust the pH of the solution to 11.5 to obtain an alkalized raw material liquid, then add Hypersperse MDC708 scale inhibitor to the alkalized raw material liquid, the mixture of Hypersperse MDC708 scale inhibitor and cobalt raw material The mass ratio is 0.15:100, and the cobalt salt solution of cobalt chloride and cobalt oxalate with a cobalt salt concentration of 0.3 mol / L is obtained.

[0035] The reducing agent is added into the cobalt salt solution for pre-reaction to obtain a translucent prefabricated cobalt powder seed crystal solution. In this example, the reducing...

Embodiment 2

[0039] Preparation of 2# nano cobalt powder.

[0040] (a) The cobalt raw material is a mixture of cobalt sulfate and cobalt carbonate with a molar ratio of 5:1, and the cobalt raw material is dissolved in 3L of a water-alcoholic mixture of triethylene glycol and water with a specific gravity of 1.05 to obtain a light red raw material solution. Add solid potassium hydroxide to the raw material solution to adjust the pH of the solution to 13.0 to obtain an alkalized raw material solution, then add a dispersant, the dispersant is a mixture of poly-2-butene sodium oleate and sodium phosphate in a mass ratio of 3.5:1 The mass ratio of the dispersant to the cobalt raw material is 2:100, and the cobalt salt solution of cobalt sulfate and cobalt carbonate having a cobalt salt concentration of 0.65 mol / L is obtained.

[0041] The reducing agent is added into the cobalt salt solution for pre-reaction to obtain a translucent prefabricated cobalt powder seed crystal solution. In this exa...

Embodiment 3

[0045] Preparation of 3# nano cobalt powder.

[0046] (a) The cobalt raw material is a mixture of cobalt chloride and cobalt oxide with a molar ratio of 10:1, and the cobalt raw material is added to 4.5L of a water-alcoholic mixture of ethylene glycol and water with a specific gravity of 1.02 to obtain a pink raw material solution . Add solid sodium hydroxide to the raw material solution to adjust the pH of the solution to 9.0 to obtain an alkalized raw material solution, then add polyvinylpyrrolidone, the mass ratio of polyvinylpyrrolidone to cobalt raw material is 0.1:100, and the concentration of cobalt salt is 0.1mol / L cobalt chloride and cobalt oxide cobalt salt solution.

[0047] The reducing agent is added into the cobalt salt solution for pre-reaction to obtain a translucent prefabricated cobalt powder seed crystal solution. In this embodiment, the reducing agent is sodium borohydride, the molar ratio of reducing agent to cobalt raw material is 0.50:1, the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Oxygen content | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com