Chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane and preparation method thereof

A reverse osmosis composite membrane and reverse osmosis membrane technology are applied in the field of chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane and the preparation field of the above-mentioned polyamide reverse osmosis composite membrane, which can solve problems such as immature technical solutions and avoid easy flushing. The effect of drop, improved contamination resistance, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Preparation method of chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane

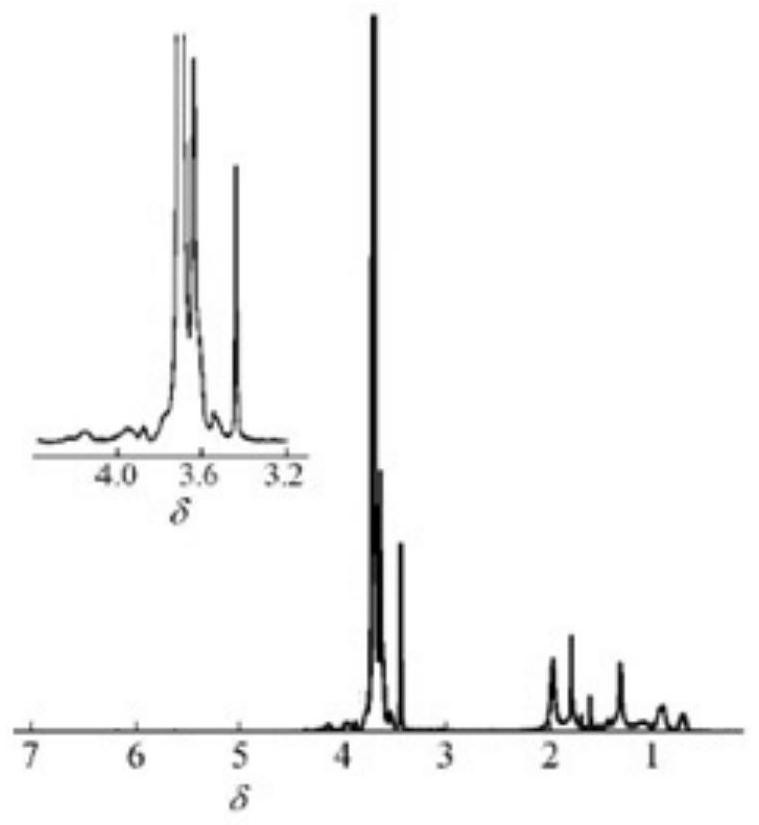

[0068] Preparation of 3-(trimethoxysilane) propyl acrylate-copolyethylene glycol methyl ether methacrylate copolymer: 3-(trimethoxysilane) propyl acrylate and polyethylene glycol methyl ether Methacrylate (weight-average molecular weight 300) is added to a mixed solvent of tetrahydrofuran and chloroform with a volume ratio of 1:1 according to the molar ratio of 1:2, and then the initiator azobisisobutyronitrile of 1 wt% of the total monomer weight is added , and then reacted at 75°C for 24h under nitrogen atmosphere. After the reaction was completed, n-hexane was used as a precipitating agent to obtain 3-(trimethoxysilane)propyl acrylate-co-polyethylene glycol methyl ether methacrylic acid by co-precipitation method Ester copolymer (weight-average molecular weight: 50,000-60,000), and dried under vacuum at 40°C for 24 hours to obtain copolymer powder. The NMR...

Embodiment 2

[0072] Preparation of chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane: except that the concentration of 3-(trimethoxysilane) propyl acrylate-co-polyethylene glycol methyl ether methacrylate copolymer is formulated as 500ppm, In the same manner as in Example 1, a chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane was prepared.

[0073] The obtained chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane has an initial desalination rate of 99.7% and a permeation flux of 34.6L / m 2 / h, after evaluating the chlorine resistance of sodium hypochlorite solution, the desalination rate is 99.3%, and the permeation flux is 36.7L / m 2 / h, the rate of decrease of water flux after pollution is 10%.

Embodiment 3

[0075] Preparation of chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane: except that the concentration of the ethanol solution of 3-(trimethoxysilane) propyl acrylate-co-polyethylene glycol methyl ether methacrylate copolymer is prepared as 1000ppm In addition, the same manner as in Example 1 was carried out to prepare a chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane.

[0076] The obtained chlorine-resistant and pollution-resistant polyamide reverse osmosis composite membrane has an initial desalination rate of 99.7% and a permeation flux of 34.1L / m 2 / h, after evaluating the chlorine resistance of sodium hypochlorite solution, the desalination rate is 99.5%, and the permeation flux is 36.3L / m 2 / h, the rate of decrease in water flux after pollution is 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com