Block lignin-silicon dioxide composite aerogel

A composite aerogel and silica technology, applied in aerogel preparation, silicon compound, colloid chemistry, etc., can solve the complex operation, limited application range, poor strength of modified silica aerogel felt, etc. problems, to achieve the effect of simple preparation method, high near-infrared reflectivity, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

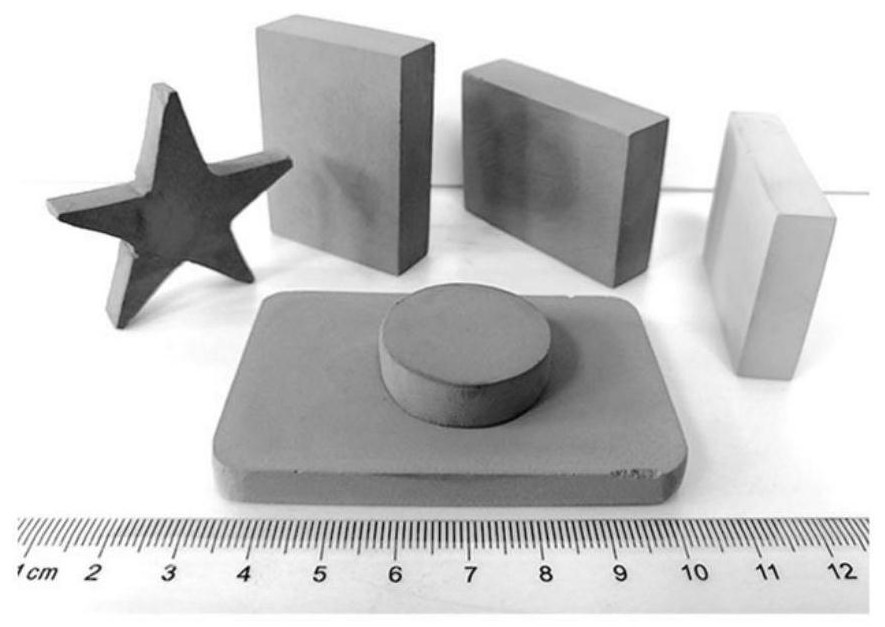

[0052] Blocky lignin-silicon dioxide composite airgel, the preparation method of which comprises:

[0053] Dissolving lignin, cross-linking agent and catalyst in polyol, and chemically cross-linking to construct lignin pre-crosslinking network to obtain pre-crosslinking lignin liquid;

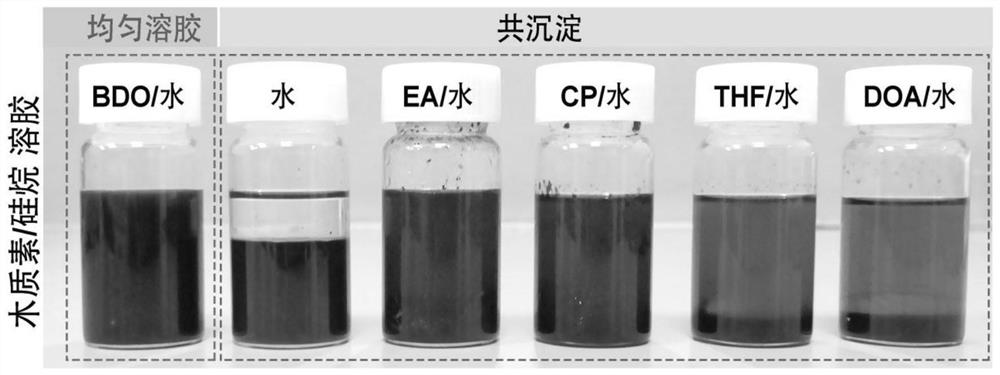

[0054] Add silica precursor, silane coupling agent and deionized water to the pre-crosslinked lignin liquid to carry out hydrolysis and polycondensation reaction to obtain lignin / silica cogel network;

[0055] Fully contact the lignin / silica cogel network with a neutral or acidic aqueous solution to carry out hydrophobic self-assembly of the lignin network and in-situ mineralization of the silica gel. After the reaction is sufficient, dry and anneal to obtain a block In the lignin-silicon dioxide composite aerogel, the aqueous solution is a solution that cannot or hardly dissolves lignin.

[0056] The polyol is a good solvent for lignin, which can well dissolve or disperse lignin and lignin pr...

Embodiment 1

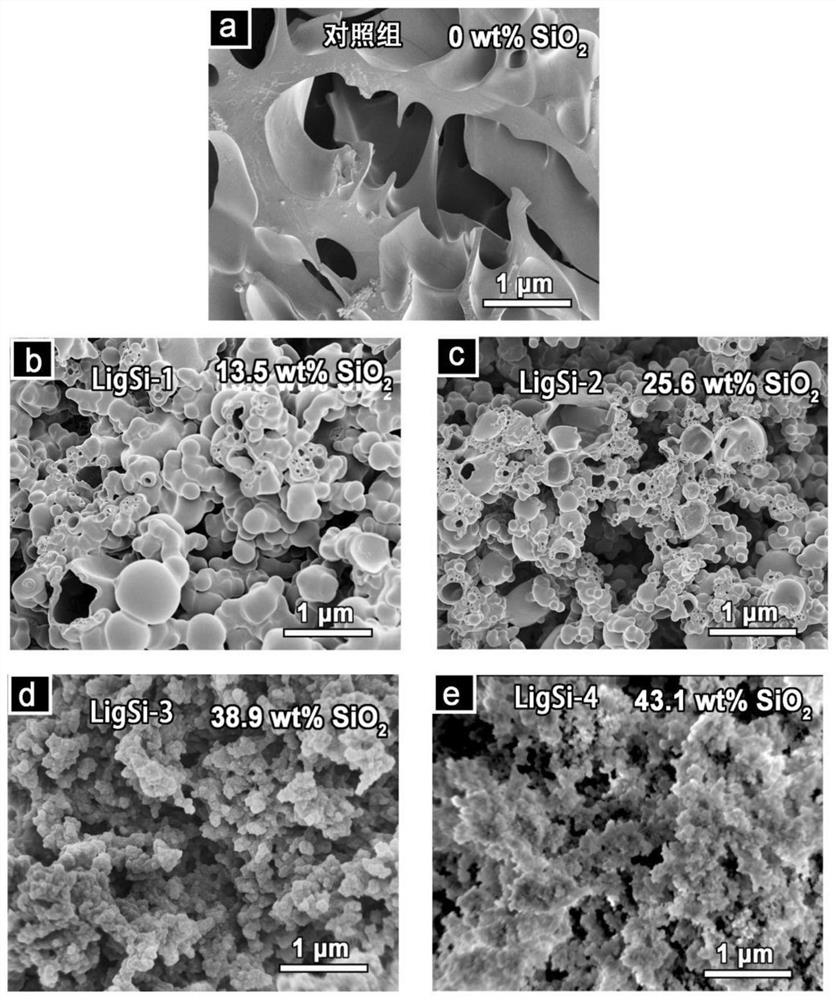

[0083] Example 1: Preparation of three-dimensional bulk lignin / silica composite airgel (LigSi-1)

[0084] The lignin is enzymatic lignin derived from corncobs (Shandong Longli Biotechnology Co., Ltd.), the cross-linking agent is propylene glycol diglycidyl ether (PGDE), the solvent is 1,4-butanediol, and the catalyst is triethylamine , Methyltrimethoxysilane (MTMS) is selected as the silica precursor, and 3-aminopropyltrimethoxysilane (APTMS) is selected as the silane coupling agent.

[0085] Dissolve 2 g of enzymatic lignin in 11 mL of 1,4-butanediol, then add 3 g of PGDE and 0.1 g of triethylamine, and stir at 60 °C for 1 h to form a pre-crosslinked lignin network. Add 1 g of deionized water to the above solution and stir at room temperature for 1 h, then add 2 g of MTMS and 0.5 g of APTMS in turn, and continue stirring for 20 min to promote the dissolution and hydrolysis of silane in the solution, and then the obtained homogeneous sol Transfer to a polystyrene container, a...

Embodiment 2

[0088] Example 2: Preparation of three-dimensional bulk lignin / silica composite airgel (LigSi-2)

[0089] The lignin is enzymatic lignin derived from corncobs (Shandong Longli Biotechnology Co., Ltd.), the cross-linking agent is propylene glycol diglycidyl ether (PGDE), the solvent is 1,4-butanediol, and the catalyst is triethylamine , Methyltrimethoxysilane (MTMS) is selected as the silica precursor, and 3-aminopropyltrimethoxysilane (APTMS) is selected as the silane coupling agent.

[0090] Dissolve 2 g of enzymatic lignin in 19 mL of 1,4-butanediol, then add 3 g of PGDE and 0.1 g of triethylamine, and stir at 60 °C for 1 h to form a pre-crosslinked lignin network. Add 1.7 g of deionized water to the above solution and stir at room temperature for 1 h, then add 6 g of MTMS and 1.5 g of APTMS in turn, and continue stirring for 20 min to promote the dissolution and hydrolysis of silane in the solution, and then the obtained homogeneous The sol was transferred to a polystyrene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com