Preparation method of marine plant polysaccharide anti-adhesion material

A marine plant and anti-adhesion technology, which is applied in drug delivery, medical formula, surgery, etc., can solve the problems that sodium hyaluronate is easy to cause fever, polylactic acid degrades for a long time, and the human body is easy to cause inflammation, etc., so as to prevent adhesion and facilitate Manipulate, reduce the effect of manipulating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

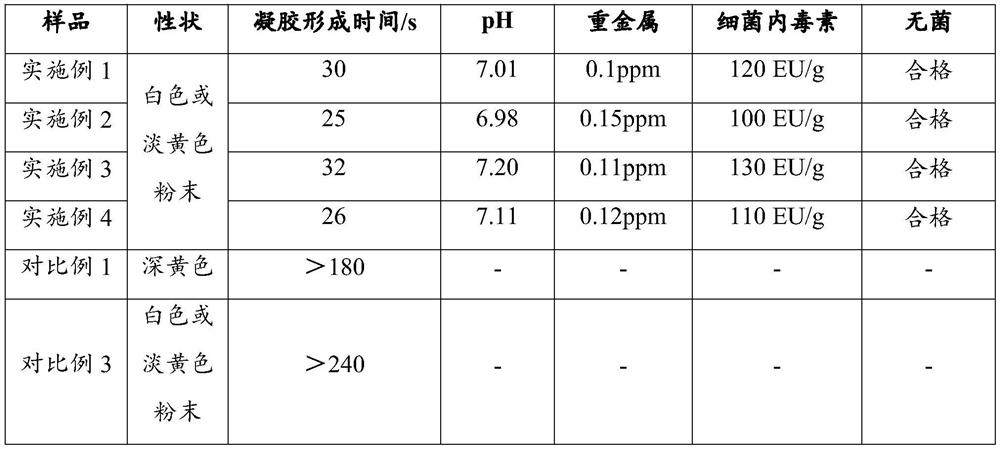

Embodiment 1

[0026] A preparation method of marine plant polysaccharide anti-adhesion material, the specific steps are as follows:

[0027] (1) Dissolve commercially available pharmaceutical excipient grade sodium alginate with a molecular weight of 10,000 in 0.4% w / w sodium chloride aqueous solution to make a solution with a concentration of 2% w / w; add activated carbon, activated carbon and alginic acid The mass ratio of sodium is 3:1, stir at 30°C for 4 hours, centrifuge the mixture at 9000 rpm for 30 minutes, and take the supernatant to obtain sodium alginate solution;

[0028] (2) With stirring at 50°C and 500rpm, add 1% w / w calcium chloride to the sodium alginate solution obtained in step (1) through a 26G injection needle to form gel microspheres, continue to stir for 2 hours, and centrifuge at 9000rpm After 30 minutes, take the precipitate and wash the gel microspheres fully with distilled water;

[0029] (3) Stir and soak the gel microspheres cleaned in step (2) in a lactic acid ...

Embodiment 2

[0034] A preparation method of marine plant polysaccharide anti-adhesion material, the specific steps are as follows:

[0035] (1) Dissolve commercially available pharmaceutical excipient grade potassium alginate with a molecular weight of 30,000 in 0.6% w / w sodium nitrate aqueous solution to make a solution with a concentration of 2% w / w; add activated carbon, activated carbon and potassium alginate The mass ratio of the mixture is 3:1, stirred at 40°C for 3 hours, centrifuged at 10,000 rpm for 20 minutes, and the supernatant was taken to obtain a potassium alginate solution;

[0036] (2) Under stirring at 50°C and 1000rpm, add 5% w / w calcium gluconate through a 20G injection needle into the potassium alginate solution obtained in step (1) to form gel microspheres, and continue stirring for 1.5h at 10000rpm Centrifuge for 20 minutes, take the precipitate and wash the gel microspheres fully with distilled water;

[0037] (3) Stir and soak the gel microspheres cleaned in step ...

Embodiment 3

[0042] A preparation method of marine plant polysaccharide anti-adhesion material, the specific steps are as follows:

[0043] (1) Dissolve oxidized sodium alginate with a molecular weight of 100,000 in 0.9% w / w sodium lactate aqueous solution to make a solution with a concentration of 2% w / w; add activated carbon, the mass ratio of activated carbon to oxidized sodium alginate is 3 : 1. Stir at 50°C for 0.5h, centrifuge the mixed solution at 12000rpm for 15min, take the supernatant to obtain an oxidized sodium alginate solution;

[0044] (2) Add 10% w / w calcium nitrate to the oxidized sodium alginate solution obtained in step (1) through a 24G injection needle under stirring at 30°C at 1500rpm to form gel microspheres, continue stirring for 1h, and centrifuge at 12000rpm After 15 minutes, take the precipitate and wash the gel microspheres fully with distilled water;

[0045] (3) Stir and soak the gel microspheres cleaned in step (2) in a lactic acid solution of pH=4 for 10 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com